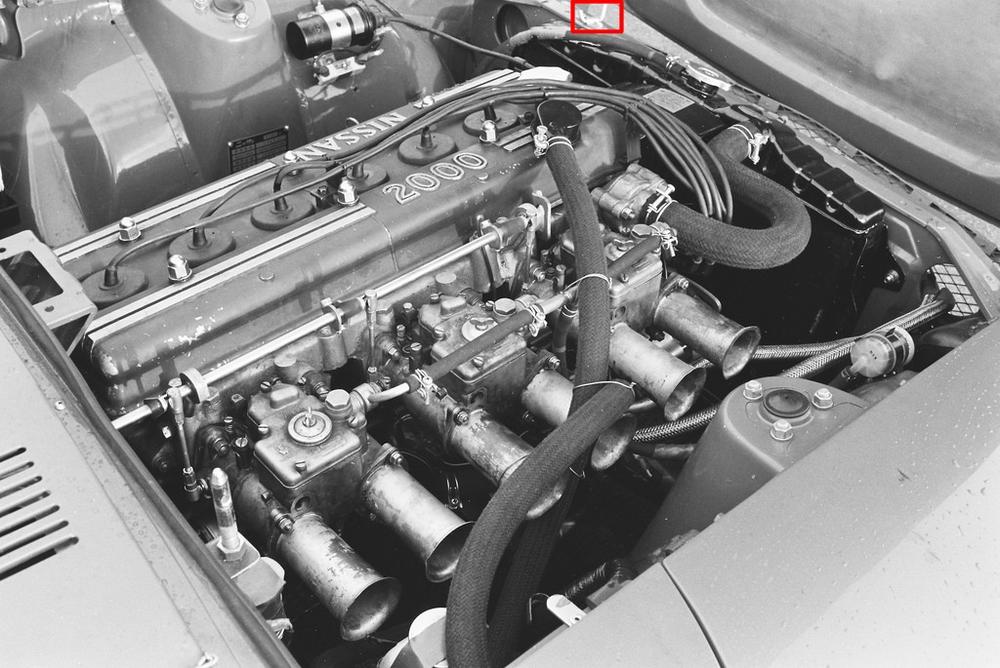

Interesting clip. Too bad there's not another one available that illustrates the flow around the back of the car, where the other half of the Z's issues reside (front-end lift being the issue at the front).

I spent almost 15 years of my engineering career with a Canadian company that was one of the four world leaders in wind tunnel design in the day (the others were Sverdrup in the USA, TLT in Europe, and Meidensha in Japan). For reference, my company (DSMA International -- now reborn as Aiolos Engineering) designed and built the Porsche wind tunnel in Weissach back in the late 1980's and later designed the Williams Grand Prix Engineering wind tunnel in the early 1990's. We also worked for Volvo, SAAB, Honda, Ford USA and Europe, GM, Chrysler, Hyundai, BL Cars, as well as for clients in the aerospace and fuel/lubricants sectors. Those were interesting days.

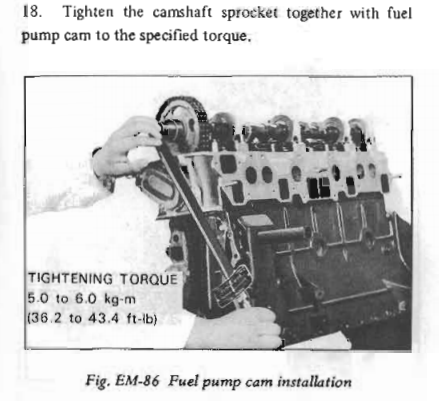

The picture of the old Nissan wind tunnel shows a rather old-fashioned design (even for its time) with an open circuit layout (affects efficiency), a small test room cross-section (affects accuracy), and the absence of an in-floor measurement 'balance' (floor/ground effect ignored, yaw measurements complicated or ignored). In terms of absolute accuracy for Cd measurements, it probably couldn't do much better than +/- 3 to 4 %. By contrast, a modern tunnel delivers +/- 1% or less. Nissan replaced this tunnel with a much larger and more capable, closed-return circuit design sometime in the late 1970's or early 1980's (it was in place and operational when I visited circa 1988).

Production car aero development was in its infancy at the time when the Z was being designed. The oil embargoes in the early 1970's were what really made the industry get serious (Americans will remember the 55-mph national speed limit as another component of the 'energy crisis' days, while Nissan captured the spirit of the times with its marketing slogan, 'Datsun Saves'). There was major industry investment made in the acquisition of modern, high-accuracy/capability wind tunnels throughout the 1980's, as well as for accommodating the cost of aero test/development hours into new-model development budgets. It's all become pretty formulaic now, but that's because of all the ground-breaking work that was done in those new wind tunnels throughout the 1990's. I remember that one of the important issues that designers were trying to sort out was how to optimally locate and size the extractor vents to enable effective cabin air flow-through. As all of us Z owners know, this was something that Nissan hadn't really got a handle on when the Z was being developed!

Subscriber

Subscriber 4Points1,333Posts

4Points1,333Posts