-

1971 HLS30-14938 "Lily" build

Thanks Jim! Thanks for the input Garrett. I was using google exactly that way and couldn't find it...

- Looking for Turn Signal Switch Upgrade

- Extremely Confusing Brake Travel

-

1971 HLS30-14938 "Lily" build

I hate the modern search engine! Useless! Shows you it thinks you want instead of what you asked for... There is a thread on the forum, not an ancient thread, that shows how to replace the window sweeps on the the chrome door trim. I was going to reread it to see how he dealt with some issues I'm having but I can't find it now :( Can somebody help? Maybe the librarian?

-

1971 HLS30-14938 "Lily" build

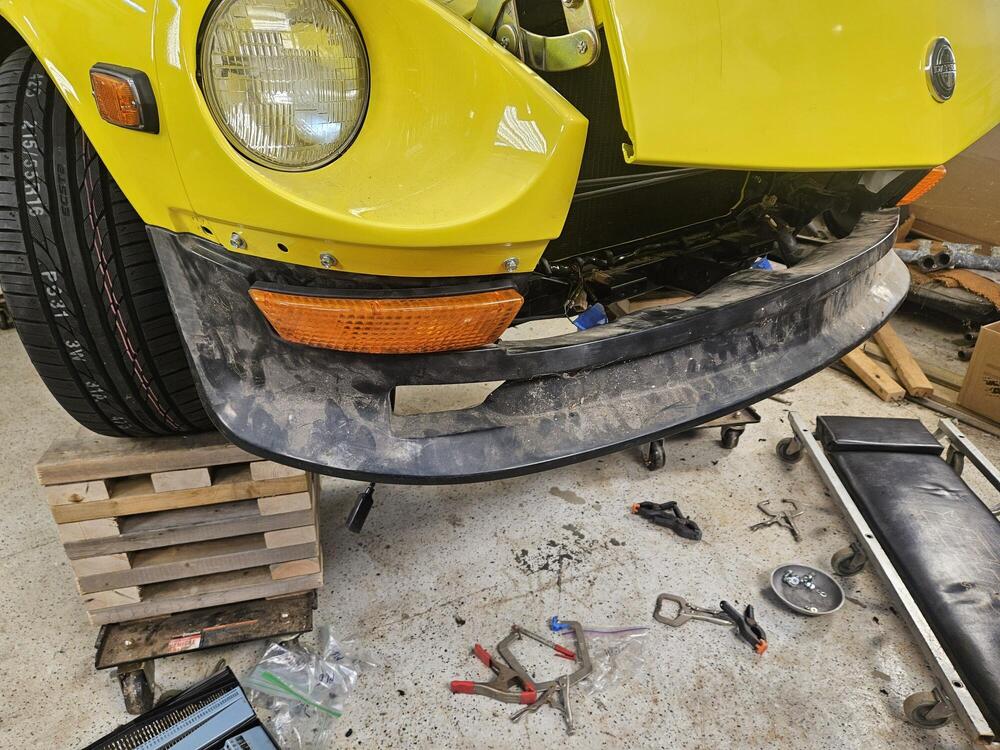

I did a quick alignment on the front wheels today I mounted the air dam up to the car and test fit the turn signals I worked on the chrome trim sweeps for the door glass but I need some pictures of how they mount. Even with the rear of the door shell? Rubber trimmed inside of the chrome frame? I assume I will have to trim the rubber in place otherwise you might trim the front angle in the wrong place

-

Clear Tail Light Lenses for 1979–1981 Datsun 280ZX

How about making lens for other Datsuns?

- Looking for Turn Signal Switch Upgrade

-

Z's on BAT and other places collection

I like stock cars but I also like modified cars. I like it when hybrid cars use a driveline from the same manufacturer. If I didn't have so many projects I would consider taking that one on...

-

1971 HLS30-14938 "Lily" build

The door latches I used Tail light chrome pieces. They weren't very flat. So I heated them slightly to reshape them. I did cause some wrinkling in the finish on the one that was pretty warped. I probably should have sent them back and exchanged them but for now it's fine Bought some washer to hold the trims on Installed Some butyl to hold the lens in The center post of the chrome is supposed to be long enough to go all the way through the back and get another star washer. The posts on my repops aren't long enough for that. So hopefully the lens don't fall out Felts for the bottom lens drains Shop dog More Belmetric Lights in place Finishers Badges, because everyone knows badges make cars run better!! ;)

-

Z's on BAT and other places collection

https://bringatrailer.com/listing/1972-datsun-240z-366/

-

Guy's wanting my 240

Yeah, I like that Turbo 930

-

Euro / JDM taillight wiring

So factory operation of the JDM tail light?? Reverse is reverse Turn signal is turn signal and flashers Both upper red lamps are parking lights? Only one upper red lamp is brake light? Maybe the outboard one?

-

Z's on BAT and other places collection

My suspicion is the lighter plate is for the very early cars. The later iterations were heavier

-

Euro / JDM taillight wiring

Can anyone post up a JDM or Euro version of the wiring diagram for the tail lights to identify wire colors? @kats @jonbill @HS30-H

-

vin number

I do not believe that information is available. The Marti report came about when Ford was going to dispose of all the build sheets from that era. Somebody aquired them and saved them. When you get a marti report they are finding the proper build sheet and providing the info, for a fee. IIRC

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber