-

ARA air conditioning installation instructions

https://www.zcar.com/threads/1972-240z-with-ara-air-conditioning.356474/

-

Fuel Line Blockage - New Cleaning method

-

DIY FOAM Build

- Parts for Sale: SIX 45mm velocity stacks

View Advert SIX 45mm velocity stacks Selling for a friend who accidentally bought these for his 40mm carbs. These are for 45 mm throats 50mm height Fit Weber, Mikuni, and SK Racing / OER $300usd shipping included Advertiser 240260280 Date 10/07/2021 Price $300 Category Parts for Sale- Tuning With An Air/Fuel Gauge

tvs is often referred to as tps. Not sure on afm sticking. It would certainly reduce air flow if the flap stuck.- COVID-19

- Tuning With An Air/Fuel Gauge

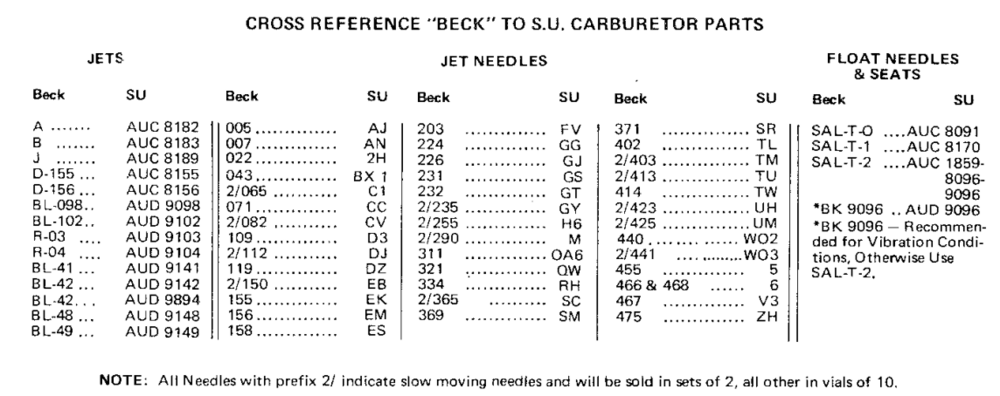

Only TVS is connected to the pedal.... look there- Mystery SU Needles -- "369"

Life and rediscovering synths... yes I was deeper into them than datsuns.- Mystery SU Needles -- "369"

- 1970 240Z SN 556 on CL in Austin TX Area

556 for sale again... up from the $1,800 above. https://www.ebay.com/itm/165013655212?hash=item266b948eac%3Ag%3A-GIAAOSwz1NgndTv&LH_ItemCondition=4- What is your most valuable 'made-it-myself' tool?

You kids and your late model modern cars!- What is your most valuable 'made-it-myself' tool?

- What is your most valuable 'made-it-myself' tool?

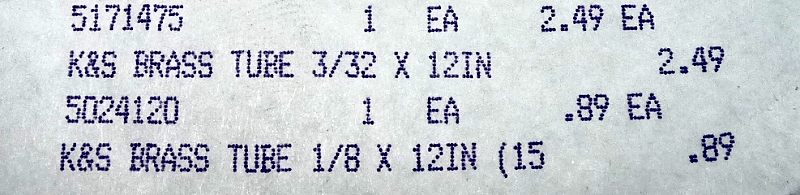

It is for aligning the nozzle sleeve (that holds the jet) to the centre of the piston. If you disassemble the bottom of the carb, you will find the nozzle sleeve has freedom to be repositioned within the nozzle sleeve set screw:- What is your most valuable 'made-it-myself' tool?

I think @zKars can fill 10 pages!- What is your most valuable 'made-it-myself' tool?

- Parts for Sale: SIX 45mm velocity stacks

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.