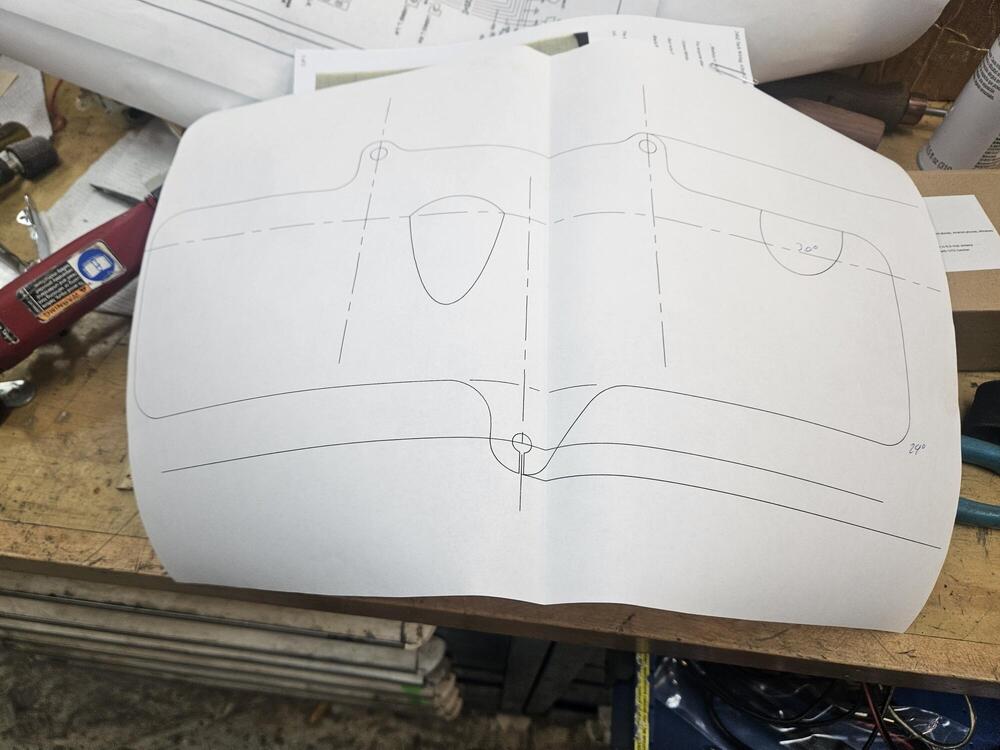

If you follow me on social Media, you might have noticed that I spent the last 10 days in Japan with my fellow S30.world friends for a very special once-in-a-lifetime experience. I'll post multiple detailed stories on this website soon, but I still need to process it all in my brain and go through thousands of photos. What I can show you already is what I brought home from Japan, aside from all the business-cars and fresh S30.world clothing (not pictured): First, a set of Papers with the "Nissan logo": Those are the ones that Nissan dealers usually put in new cars to protect the carpets. We had them at our Car show in Japan to protect the floor from tire-marks. As we had a lot of them leftover in the end, I thought i stuff two in my suitcase :-) I also got various stickers. From the old NISMO logo stickers, which I bought in the Nissan HQ Gallery in Yokohama, to a handwritten Kanji-version of my name, to various stickers of the event, and a sticker that me a local Honda dealer gave when we checked out their cars. Some went of course directly onto my new "Hall of Fame": I was also very fortunately to buy one of the very last RS-Mach "Ura Mach" steering wheel from the maker himself. I have planned a detailed story on this blog about the Mach steering wheels, so stay tuned, if you want to know more. He sold all the remaining ones he had on this very day and doesn't plan to make new ones. I also came home with a lot of Magazines and catalogues. From the Protec catalogue to the Nostalgic hero (showcasing the new NISMO DOHC head, which we would be able to check out the next day), to the nice Motorfan Fairlady special edition which I was gifted by Endo-San, To the new Motor magazine 70th anniversary edition by Editor Morita-san, which joined us during the first days of our trip. At RS-Watanabe we got gifted with a nice bag that also included a lovely box with their iconic Watanabe 8-spoke wheel as a miniature keychain version. Lovely! From Morita-san i was gifted the lovely pin in exchange for a document I gave him and from Jeff we got gifted some ZCon keychains and a group Z sports car club Bolt tray. The bolt-tray went directly on my car lift: Then we also got gifted a set of reproduction rubber plugs for the drum brake drums from a good friend and Endo-san handed out NOS spare bulbs in original packing, which will be excellent to put in the glovebox :-) In a local toy-store we found a box full of mini 240Z's for 90 cents a piece, so I got a bunch of them as a gift for customers :-) From one of the Japanese participants of the show, we got gifted these lovely 70ties scanned magazine covers from two Japanese 1971 "Autosport Young" magazines, which assemble to a nice poster when you put them together. Aside from the naked lady, you see all the Nissan Fairlady Z Works race drivers in front of one oft their racing cars. I framed it and hung it in a nice place in the garage: We also got gifted some copies of hand made sketches by Tamura-san, one of the original designers of the S30 car, plus a nice photo from a LHD prototype car: Then I also got this. I understood that this is some kind of rating chart and something very special, somehow linked to Sumo battling, but still have to find out what exactly it means. Another cool thing was this S30.world Japan expedition Lego kit: Which, when you assemble it, turns into an S30 under a Japanese Torii gate with the S30.world logo on it: I was lucky my suitcase didn't burst. I would have loved to buy more stuff, there was definitely no more room for that, and that's fine for my wallet too :-) Expect more updates from our Japan trip soon!

Subscriber

Subscriber 15Points11,182Posts

15Points11,182Posts Subscriber

Subscriber 10Points1,975Posts

10Points1,975Posts