Leaderboard

-

conedodger

Free Member930Points12,616Posts -

Captain Obvious

Free Member459Points10,111Posts -

siteunseen

Free Member379Points15,164Posts -

Patcon

Subscriber

Subscriber 368Points11,171Posts

368Points11,171Posts

Popular Content

Showing content with the highest reputation since 12/06/2024 in all areas

-

Z's on BAT and other places collection

12 pointsDear all, My name is Chris Visscher and I am the owner of S30.world. For the past 10 years, I have focused a significant part of my life on increasing the appreciation of the Datsun 240Z/Nissan Fairlady Z, which we all cherish. With my partner Gustav combined we did about a total of 60 restorations to date. I would like to thank everyone here for their feedback. We are removing the white 240Z with VIN HLS30-15662 from the masterpiece program. You are right, the underside of the car has been completely repainted, and that should not be the case. The press release states that it is factory correct. You are right, it should say: as close as possible to when they left the factory. I am the last person to admit that a complete factory-correct restoration is impossible. All I can say is that we did our very best and made special rubber mats (for the 1969 cars), special air ducts(for the 1969 cars), a fuel tank for each of the different years, the insulation mats under the paint on the bottom, behind the dashboard , etc.etc etc I myself have dismantled many cars that were produced from October 1969 to the end of 1970 and compared all the parts with other project cars. So I have done everything to gain experience. In addition, we have different first paint cars starting with #2xxx and #19xxx that we have used as examples. We will certainly have made mistakes, but I can tell you that we have done everything we can to do it as well as possible. I am proud of the result and I hope you are too! I'm also very proud about the team we put together from all over the world. JAPAN, USA, UK, SWISS, GERMANY, AUSTRALIA, HUNGARY. They are all giving there free time to get appriciation for the S30 to another level. S30.world - The platform . Please read about it. If you want to help us and the community and have further feedback on the cars or the website, please email it to chris@s30.world, I appriciate it very much! Thank you in advance for your help.12 points

-

The Development Story & Specification Of The European Spec Datsun 240Z

Here's another great S30.world article, this time focusing on the development of the 'Euro' spec Datsun 240Z, exploring the circumstances which necessitated its creation and the people behind it. It includes some - precious! - original hand-written development note documents which we are privileged to have access to after all this time, thanks to our fellow member @kats Very nicely put together and written up by another of our fellow members here Nils @JDMjunkies.ch Tip of the hat to Florian at S30.world too. This is a topic not often acknowledged let alone discussed, and yet it is a fascinating window into a significant part of the S30-series Z's family tree. Recommended reading: https://s30.world/articles/european-spec-datsun-240z11 points

-

Z's on BAT and other places collection

10 pointsGood morning and greetings from Germany/Europe. After reading along here for a long time, I am now introducing myself as the ‘marketing guy’ from S30.world. Even if this might be a mistake, because I'm speaking up as a "newbie" and will surely get 40 knives rammed into my back. But I'm willing to take that risk. So please forgive me if my language isn't perfect and I don't know most of the people here in the forum. I think the community here has been connected for a very long time and it's difficult to let someone outside the USA into the "inner circle". But let me at least try, and I hope that a certain amount of friendliness in all directions will certainly do everyone good. As Chris already wrote, we are busy every day doing our best and put a lot of effort into understanding and paying attention to every detail as best we can. Of course, the fact that our team is located all over the world also plays a major role in this. We are in the Netherlands, Hungary, Switzerland, Australia, England, Japan, the USA... This is very important because the S30 series was not developed solely for Japan, nor solely for the USA, nor solely for Europe. The entire S30 family is a globally designed car. And every export market is different (even though, as we know, the USA makes up a large proportion of exported cars). But not many people know that European cars are significantly different from those in the USA. The fact that cars in Portugal are also VERY different from cars in the rest of Europe is also an interesting story. But why is that? What impact do laws in Australia have on cars in the USA, for example? What do changes to cars in Japan have to do with cars in Europe? Why are there still 260Zs and no 280Zs in Europe and other export countries in the years 76-78, while in the USA it is the other way around? These are all questions whose answers are connected like a tight net. So you should never look at just one export market. That would not be the whole story. We, as a group of people spread across the globe, gather our knowledge and try to answer questions. (For example: who knew that between 1969 and 1978 there were 10 different factory hubcaps for the Zs?) We are simply passionate nerds who not only restore cars, run a museum and reproduce parts, but are also on the hunt for all these undiscovered mysteries. I think it matters less which words in our press release are "allowed" from this forum – because surely it is also our goal to appeal to people who haven't owned a Z for 50 years, but are new to the topic. Above all, it's about sharing all our experience (people are already laughing about the fact that I was born in a Datsun. My family has been driving Datsuns since the early 1970s, and the first car I ever sat in was a 1973 Cherry E10, a model that wasn't even available in the USA) and to create a place that inspires all Z fans worldwide. I therefore invite all sceptics to visit our museum in the Netherlands and take a look at the cars. It's certainly exciting to see how they are built. Incidentally, we are very grateful if anyone on location notices that, for example, a screw is the wrong colour or a hose does not have the correct number. But please don't judge something like that just because you see photos on a computer screen. Come and visit, you are invited, and I am sure that we are all nice people who share the same hobby.10 points

-

The OG 240Z - Reanimation Project

10 pointsProof I made it! This is at the judged show. I wasn't ever able to register though because I think it was full. But the zcon organizers liked the car and told me to park it on the show field anyway. Im honored!!10 points

-

Little Shop trick to share. Installing Sun Visors and interior mirror

Some of you have dealt with this little annoyance, and I have found a perfect solution. When doing a full restoration, or at least the full interior, you often have to replace the head liner and the A pillar vinyl, as well as the vinyl trim that goes across the top of the windshield where the sun visors and rear view mirror mount. While I won’t discuss the pain of installing these items, what I have found is even more of a pain, is finding the nine M5 threaded holes to put the visor and mirror mount back in. All that fresh painfully installed lovely vinyl, and 9 secret little holes you have to find to poke holes through. Get out the pokey thingy of your choice and start poking until you find them. If you put some kind of thin foam behind the vinyl like you’re supposed to, those damn holes are just a nightmare to sleuth out. Not any more! I put some nice long M5 grub screws in the nine threaded holes, THEN do the upholstery. Then finding the tips of them sticking out is easy! Make little “X” slits to expose them, grab your M3 hex key, back them out and screw in the visor and mirror mounts. Five minutes each! Easy peasy.10 points

-

Z's on BAT and other places collection

Hello, everyone. I am also a member of S30 World. I’m very happy to be a member of the team. Thank you Carl. Carl recommended me to Chris’s big project. In addition, I definitely thank Alan for promising to join the team because I am a member. Chris visited my house in 2018. I was very impressed that he was very sincere about all the variations of our car. And his dream was to establish and enrich the museum with cars that have received great restoration work. It’s all because of the Classic Zcar Club. We have been learning a lot from the people here. I’m making a lot of friends here. We are all connected in a simple way. Z. We know that there are no cars that have been restored 100% correctly. The S30 World is trying to restore the car close to 100% correct. Chris’s great passion is outstanding. Many enthusiasts have been involved in his project. It’s like magnets on the fridge. I think all the posts here are worth reading to make our beloved cars more beautiful. I think people who post here are like magnets too. As Florian said, we are simple. We want to enjoy the S30 more and spread the joy of our cars to the world. If you see the car at the S30 World Museum, you will surely like it. We need to correct the “100% correct” word into the appropriate word. But all the black painted floors and other little things are repaired in good faith, so even if we don’t fix it, you’ll like it. Oh, stay tune, I will report an interesting things regarding S30 World soon. Kats9 points

-

I was Surprised...

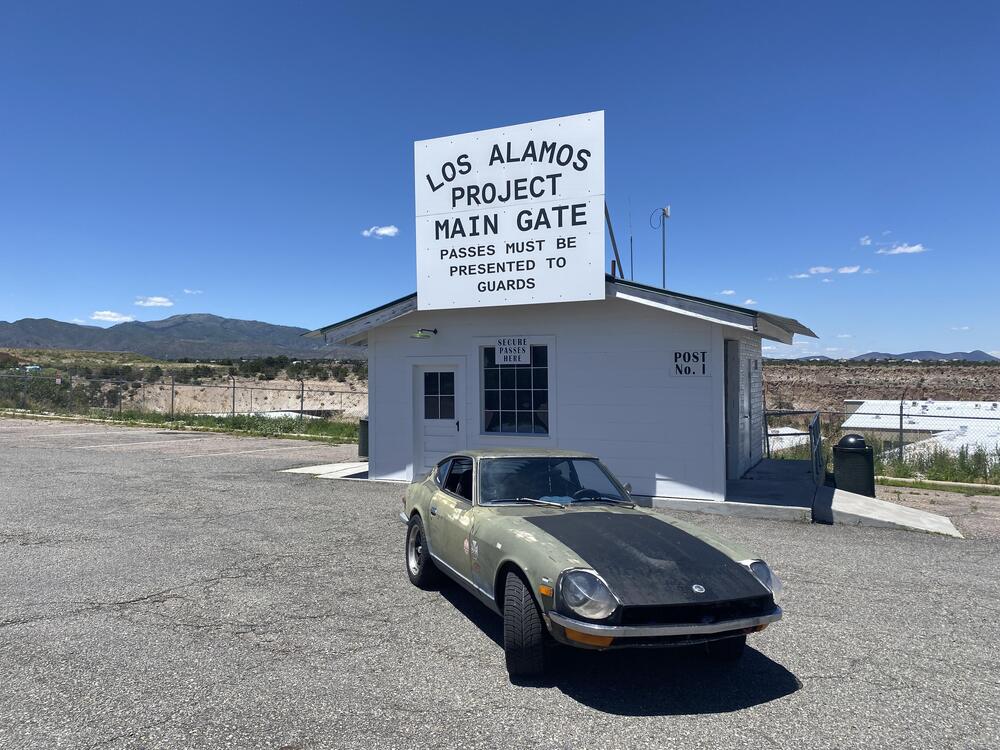

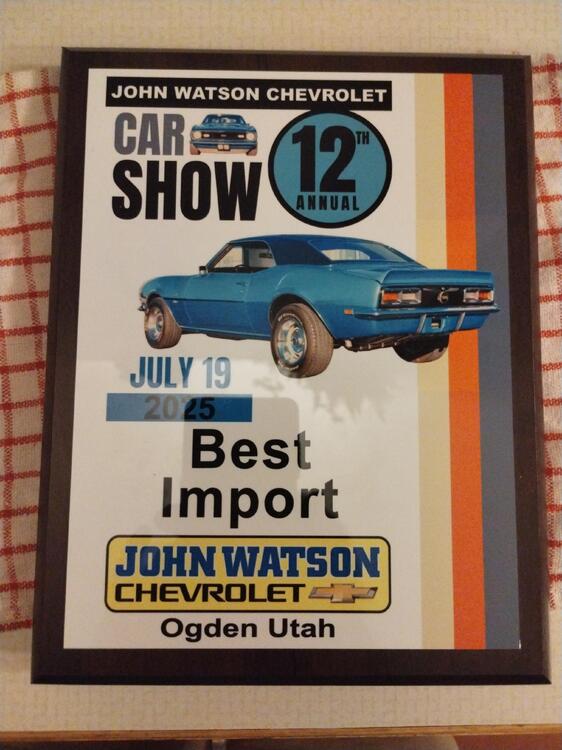

9 pointsTook the Z to a show at a local Chevy dealer. When I pulled in the dealership owner said "We never see these cars, I want you parked at the entrance".9 points

-

1971 HLS30-14938 "Lily" build

9 pointsWe checked the timing. It was about 14 with 32 or so all in Here are my mechanics Morgan is home from school for a few weekends and her boyfriend Mark was here too. They're all good with tools and willing to help9 points

-

Not dead...yet (Hi from Blue)

9 pointsHi Gang, It has been a rough ride for the past few years. I stepped back from a lot of fun things to get through. Dropping Z hobby and online activities were just part of the change. I am starting to get my strength back and tuned some carbs a few weeks ago. This was my first car activity in a few years. I am slowly coming back. I have been a hermit and reclusive. I did not keep in touch with so many good friends. I apologise. I did start to come out of the funk a few months ago and updated Jim Arnett. We had a nice chat. I also promised to update the group. Don't feel special as I also withdrew from many of my good friends here in my area. Strange how things change.... but they are changing back. In a nutshell, during the depressing covid time, Janet, my better half, got cancer and went through hell...surgery, chemo then radiation. She got better then it came back. More surgery finally took care of that #$$%%. She is good now. Once she got better, I got cancer. We were like a sorry tag team looking after each other. I did radiation with concurrent chemo from last Nov though Dec. I am finally getting strength back and starting to feel normal. All is good and last PET scan (just 2 weeks ago) finally shows no evidence of disease. Many more other horrible things seem to happen during this time but hopefully it is all behind us. I'll check back to this thread in a week. Please PM me if you wish to catch up. We can exchange phone numbers. It will be nice. kind regards and apologies to all. Philip9 points

-

Repaint Refresh of HLS-02446 3/70

9 points9 points

- Happy Anniversary To Me!

8 pointsPut on your party hats and toot your horns. Join me in celebrating the 54th Anniversary of the day I bought my 1971 240Z. Today, it sits in my driveway proudly showing its age. Unfortunately, I'm also showing my age and have a little more trouble getting in and out of it and working the pedals than I did in 1971. Great car, great fun, 54 years of great road adventures!8 points- Z's on BAT and other places collection

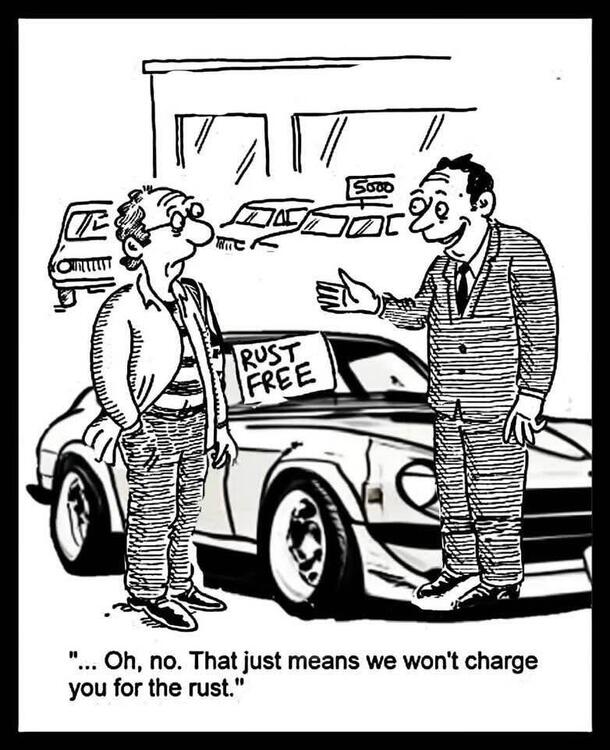

I've been very lucky on many fronts in my life. My luck started with being born in this country and continued through being born into my family. However, for this screed I'll stick to the Z world. I started getting paid, $125.00/week, to be a mechanic at a dealer in 1970, talk about luck. I very quickly realized that paying close attention/noticing things were important aspects to becoming successful at my craft. When I opened my now closed shop in 1980 a trickle of unmodified original owner Z cars started to flow through, talk about luck. It didn't take me long to understand the importance of documenting as many details as possible. The results of my appreciation are a large stack of photos of the many fine details of 240/260/280 construction. I also have many sloppy pages of notes describing the fine points of construction and differences between model years. My goodness, I even have several pages of notes describing, in detail, the fasteners used to secure a 240 timing chain cover for production date X. Every time a serious customer approached me for a restoration I would ask, in detail, exactly what he/she wanted the finished product to look like. Before they had a chance to answer I would describe what an original Z looked like from the factory and I'd often show them a few pictures from my collection. The answer was always not just no but HELL NO! They wanted pretty. What does pretty mean? Modern, often 2 stage, paint that has been wet sanded and buffed to near perfection. Powder coated suspension and all the other bits and pieces of modern restoration required to satisfy a customer. To see 2 of my last 3 Z car restorations visit my site and click on Customer Profiles. When a 240 left the factory there was orange peel in the paint in random places. Have to mention that this particular problem improved markedly in about 1975 or so. However, there was often a serious problem with the clear coat discoloring when 2 stage paint was used starting about the same time. The paint on the bottom was applied very unevenly and often contained dirt in random places. Most of the grommets that were glued in place had glue running down from the grommet. The suspension pieces were painted a sloppy and uneven satin black. There was overspray on some of the exterior engine components that were in proximity to the engine block. The list goes on from there. Please don't misunderstand me, I'm not criticizing Datsun, that was the way cars were often manufactured back in the Olden Days. I can all but guarantee that if a real factory-like restored Z showed up at a convention a trophy would not be forth coming. Now to address the hyperbole that has crept into the world of Z restoration. "Frame -off Restoration", "Rotisserie Restoration", "Factory Restoration", etc., etc., etc. There are some new ones now like "Magnificent" and so forth. The situation is often made worse with fancy photography and lighting. This is what happens when marketing geniuses get involved. Remember the Z Store Program? H@#$, now I'm often confused and don't understand what they're talking about. ALWAYS look at the car you're considering or send someone like me to have a look before making that offer. I understand that I've only lightly covered this subject but there you have it for better or worse.8 points- Found this and it would be funny if it weren’t so true

8 points- The OG 240Z - Reanimation Project

8 pointsWell I made it! Got in late and just laid low. Had a beer with my local Z buddy from home. We met along the way for the last leg near Nashville. Man was that a long trip. But we made it!!!!!! I'm not sure which surprised me more with the success... Me, or the car!!😃8 points- Z's on BAT and other places collection

If a sermon could save even one soul it would be worth preaching. I think you'd find - if you gave it the benefit of the doubt - a smattering of eager listeners in "this crowd" who would appreciate the chance to hear what you have to say. If we don't deserve it, then who does? You might look at the current exchanges on this forum and see members eagerly conversing with what appears to be an Artificial Intelligence 'bot, but over the years some of us have drilled pretty deeply into the story of these cars, the people and circumstances behind them and into their very fabric. I can think of few other open source platforms where this has been made available in the English language. Hopefully (!?) much of that still exists here and is - with effort - searchable for those who are curious and/or passionate enough to know. At the very least, put it out there before you can't. Pro Bono. Thanks.8 points- [2025] What Did You Do To/with Your Z Today?

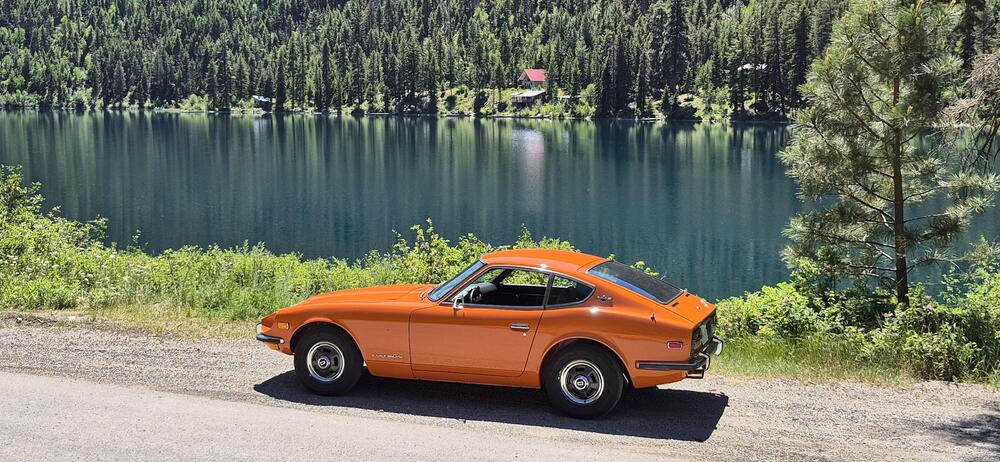

Went on my first road trip of the year with my BC Z club friends. About a dozen of us left from the Vancouver area, I joined from Chilliwack and we made our way to the BC Okanagan. Our original plan was to take the Coquihalla Highway to Kelowna, but a large sinkhole closed that route. We ended up taking the more scenic Hope-Princton Highway. For me it was a 436 mile (700km) return trip. My1970 Zed performed flawlessly, even in high mountain terrain and temperatures in the mid 30's C, (93 F), Our first stop was in Princton, for fuel, and to meet up with a few more Z club members. Here's a pic of a few of us in Princton. Our end destination was Kelowna, where Kelowna Nissan generously us hosted for a welcome event. They put on a great BBQ and offered up some Nissan swag. With other club members that met up with us along the way, there was close to twenty Zeds. The Zed to the left of me is fellow forum member @Chickenman, with his 1976 280Z. Thanks Richard, for the "way home" route ideas. The next morning, quite a few had decided to stay an extra day and enjoy the awesome wineries in the surrounding area. I and others, make the trek back, with most taking the faster, more direct Coquihalla route, as sink hole repairs had been made. I like to take the road less travelled, so I did a solo drive on a longer but more scenic route. This route included highway 5A from Merritt to Princton, that runs beside a seemingly endless series of beautiful lakes. Another bonus was that I was almost the only car on the road, with that route. 🙂 All in all, it was a great weekend. I'm looking forward to the next road trip.😎8 points- Darn Tire Jockeys

8 pointsToo funny! 😂 I routinely see cars with large rusted holes in them. They seem to work fine. Also in my state there are zero vehicle inspections! No smog, no emissions, no brake light check etc. It doesn't seem to create carnage on the roads. What does seem to create great issues is the invention of the smart phone! Which some drivers can't seem to put down long enough to get to where they're going!8 points- My two swiss S30Z Fairlady Restoration build thread

Today i got something very special, which i found in the USA: A box with "Maintenance of the Datsun 240Z Sports" Service slide films. Let me explain: The Box contains 7 small, numbered plastic cans. Each can has a dia film of colour photos (aka "Slides"). The booklet was Printed in November 1969. So it is from the very beginning of the 240Z. Additionally, there is a booklet which is called "Slide narration" the booklet contains the text to each slide. My understanding is that this was used to train workshop employees. Whoever trained them got a bunch of coloured slides which show how to maintain the 240Z in a workshop, and a book which shows what to mention for each slide. The purpose of the whole kit is also mentioned in the foreword on the first page of the booklet: I have never seen such a box before and think it's quite cool. It's basically a Service manual in colour photos. Some photos appear to be actually the same as in the black-and-white printed Factory Service manual. There are some awesome photos of Nissan works employees working on the cars. I still have to read it all and look through the photos. There are also many graphics and drawings shown, which I have never seen before, and most probably were made specifically for training purposes. I'm already looking for a dia scanner to digitalize them all and if I find time, I will share some of them with you. More updates in the coming days. I have planned some work and there is a sea-freight crate from Japan waiting for me to be picked up.8 points- New, short video of my restored 240Z

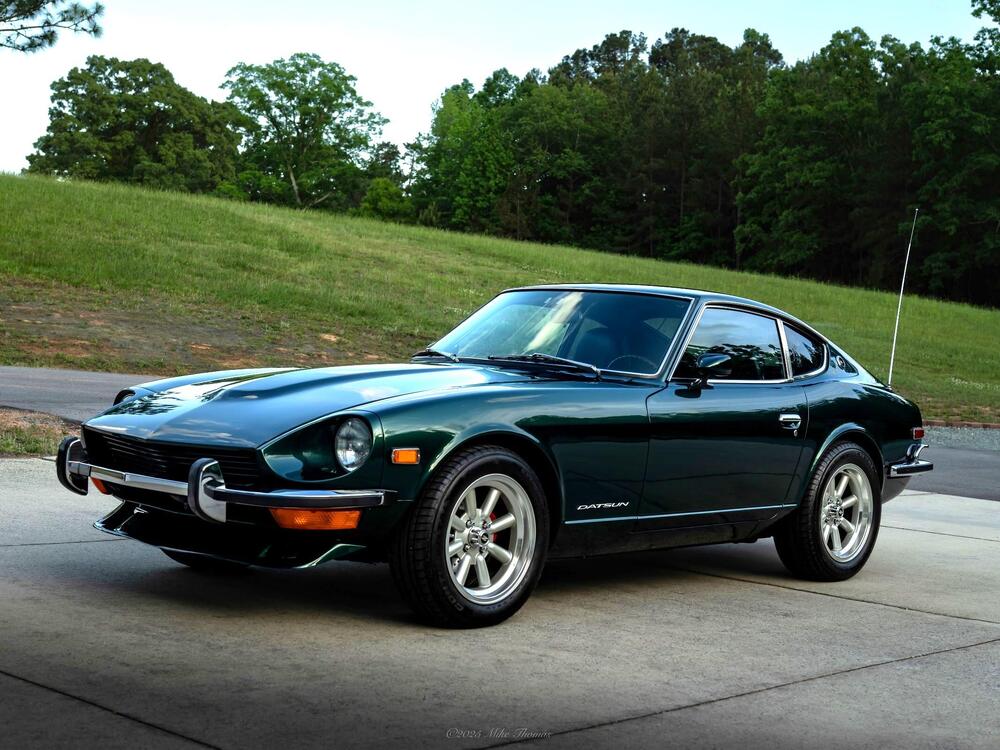

7 pointsA work colleague of mine and I spent about an hour yesterday getting some video of the 240z I restored (got it on the road on Dec 31 last year). Unlike me, he has skills and talent for editing and creating videos. Have a look! https://www.youtube.com/watch?v=nQ3ieeuqjwI7 points- Repaint Refresh of HLS-02446 3/70

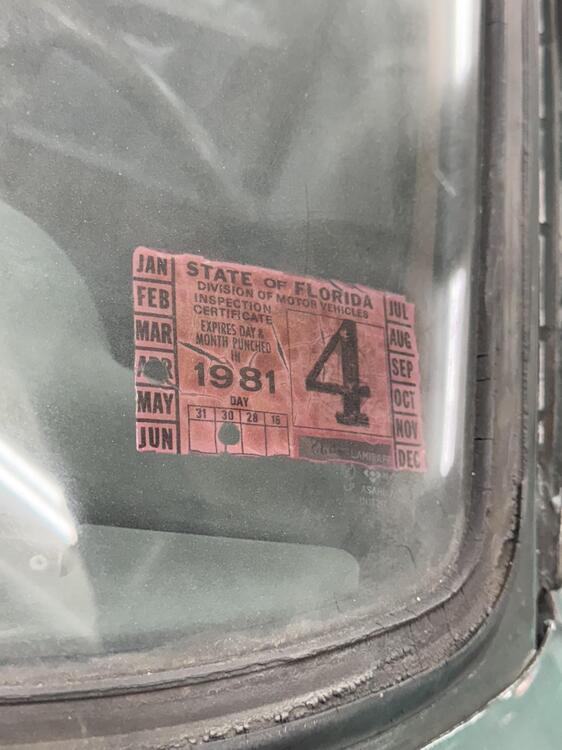

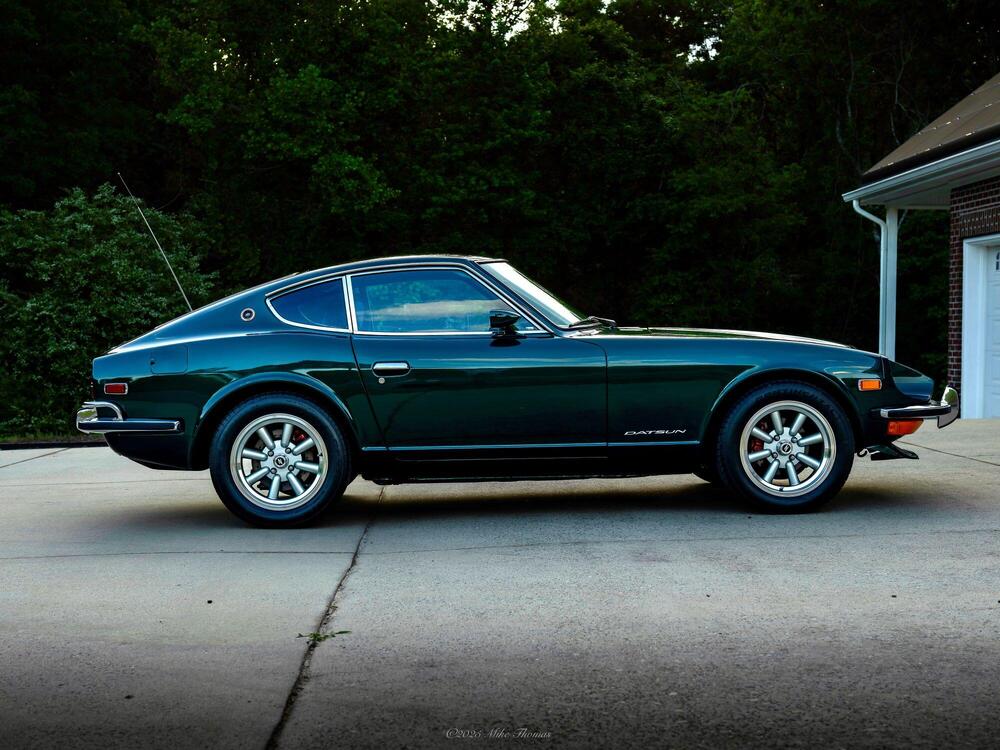

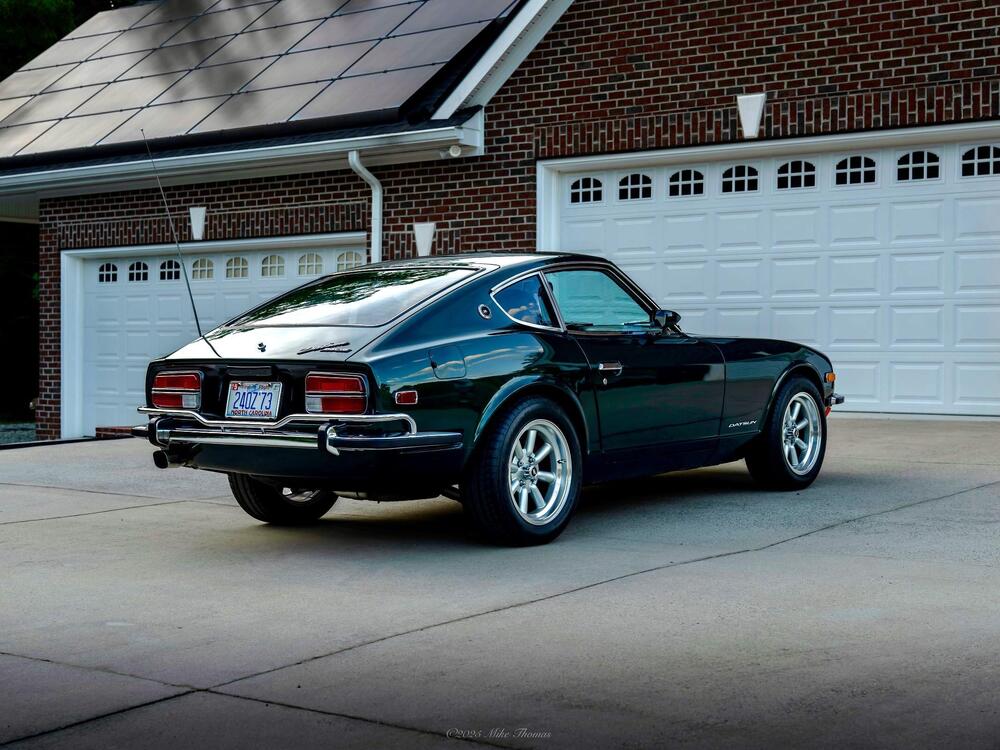

7 pointsPulled out this car after a long slumber. I purchased over 20 years ago in Orlando area from original purchaser family. Windshield shows last inspection in April 1981… Original windshield, 4 side windows dated 12/69. Hatch glass 3/70. Interior all there. Hoping to do a light refresh/clean of interior,drop the suspension, clean and paint. Engine needs to be rebuilt….”matching numbers”. Dog legs being replaced small rust area under drivers seat between alignment “flap” from rear body and floor 2”x2”. Green Tan…. My favorite combo… Wet blasting hood revealed surprisingly…. A virtually perfect hood..!!!!7 points- 240 with e12-80 plug gap

7 pointsI'm taking a year off from life. 99% of the bad ones are from pushing to fast to get back to work. Not me, I enjoy being at home.7 points- The OG 240Z - Reanimation Project

7 pointsSo I'm home. The bottom line is that the car fared better than I did. Remember in the beginning, I was worried about two things... My radiator and my back? Well the radiator didn't get any worse, but my back did. By halfway through the day at the people's choice show, I was hurting. I'll survive, but it's unpleasant. The radiator... I had talked to a couple people about the troubles I was having and they put it out on the Z network that I was looking for a radiator to get me home. Well as a result of that networking, there was a guy coming to the people's choice show that was going to bring me a radiator. We found eachother at the show, and I snagged a rad. He wasn't sure of the condition, but was optimistic about it. Said it looked good, and as far as he knew, it was in good shape. That night, @madkaw and I swapped radiators after the banquet. Out in the parking lot, draining the fluid, pulling mine out and tossing in the replacement. Now remember that my back is pretty much shot at this point, so when I say "we changed the radiator", I really mean "he changed the radiator". So when he wasn't looking, I snapped a pic of madkaw working on my car: Bottom line? We had to do the job twice, cause the replacement rad I got from the guy at the show leaked horribly and wouldn't hold coolant. Sigh. So, we drained again and put my original back in. It holds coolant fine, but has a couple clogged tubes. I'll just have to watch the temps on the way home and adjust my speeds and load accordingly. My original radiator works fine until I'm going up a long hill on the interstate at 70 on a hot day. Thankfully as I drove north, the ambient temps dropped some and I was much better off. By the time I got to Maryland, the temps had dropped enough that I was able to maintain 70-75 on the interstates without worry. Thanks to everyone along the way that helped with the trip and glad for the chance to meet some of the forum guys!! @madkaw @Ninjaneer11 @zed2 @Parman @inline67 points- The OG 240Z - Reanimation Project

7 points- Datsun 240Z Ashtray Snuffer Plate Reproduction In Stainless Steel

eBay UKDatsun 240Z Ashtray Snuffer Plate Reproduction In Stainle...Datsun 240Z Ashtray Lid Insert / Cigarette Snuffer Plate – Reproduction Part High-quality reproduction of the original Datsun 240Z ashtray snuffer plate, designed to match the look and fit of the f... Datsun 240Z Ashtray Lid Insert / Cigarette Snuffer Plate – Reproduction Part High-quality reproduction of the original Datsun 240Z ashtray snuffer plate, designed to match the look and fit of the factory part found in 1970–1973 models. Precision-cut metal complete with M3 bolts and nuts for easy installation. Fitment: Datsun 240Z (1970–1973) Material: Stainless steel Slotted snuffer design, includes M3 bolts and nuts Ideal for restoration projects or replacement of missing, broken or corrodedl parts7 points- Took some pics of my 240z side-by-side with my 2025 400z

Hello everyone, Just added the 2025 400z to my garage and wanted to share some cool pics next to my 1973 240z (which I have owned for 20yrs). With 50yrs of Datsun/Nissan Technology between both cars, there still is the purest of styling and lines that's the signature of the "Z's" that is very much recognizable. Anyway .. hope you all enjoy a few of the pics. Many thanks , Mark7 points- air cleaner housing connections

7 points7 points- 1971 HLS30-14938 "Lily" build

7 points- My two swiss S30Z Fairlady Restoration build thread

Today I was able to pick up the long-awaited sea-freight shipment from Japan with some parts I bought as long ago as June last year. I almost forgot what I bought back then, so I was excited to see what i got. The shipment originally included parts which were not for myself, so when the shipment was ready to be loaded on the boat, and then these items popped up for a good price, i just bought them blindly to use the opportunity of almost free shipping. This set is what i think an original Nissan factory adjustable suspension. I still have to check the numbers and all the details. But ut looks like it could be an original nissan set. The other (rear suspension) set looks like a reworked original strut. It has some Nissan stamps on it and obviously got repainted at some point, but it was quite cheap and looked close to factory (not like these modern designs), and it came with multiple boxes of what appears to be original Nissan suspension parts, so I added it to my delivery. The third item was a real win. a set of genuine Mikuni JP PHH44 Carbs. The price was very low, because it looks really rough. But if you studied the details thoroughly, you would see the inside is in pretty damn good shape. All the original parts are included, and the plating is still nice on most parts. And it came with an old school heat shield (not sure if original Nissan) plus a set of two modern style heat shields. Both still unused. The price was a real bargain for what you pay for those these days. And it seems to my untrained eye, that all it needs is cleanup and set of fresh gaskets. but we'll see.. Not from Japan but also delivered today was this used DiaFilm scanner which I bought online recently. So I gave it a try to scan those first original Nissan Maintenance training slides, which I bought recently I still need to figure out that colour correction and other stuff, but the first results are promising. and those slides are really, really cool! My goal is to digitalize them all.7 points- [2025] What Did You Do To/with Your Z Today?

5 weeks since surgery and it's still pretty sore. Really depends on what I do. Therapy one day, rest the next and then back for more. I'm doing a lot at home with a recumbent bike and weight bench with a leg lift I bought years ago to hang clothes on. Now they're my nemeses just like the upstairs garage apartment I've loved for so many years. The doctors say I'm halfway, 12 weeks is their recommendation for release but say it could take up to a year to feel like it never happened. Haven't taken a pain pill in 2 weeks, not saying I wouldn't take one the size of a Frisbee right this minute but the OTC Aleve plus herb(s) are working great. Happy New Year Mark and Kathy!7 points- Harmonic balancer Rubber shows deterioration

6 points- 1971 HLS30-14938 "Lily" build

6 pointsLast weekend we worked in the shop some Here is a seam in the leather fender covers. I made this with contact adhesive and clamps. I picked the padding out in the seam area so it was just leather to leather. We took Lily down off the cubes. A lot less sketchy than the way I put her up there. Still had to have a 6x6 on the jack saddle at this point Rolled her outside and it promptly rained... My windshield leaks and I will add some sealant under the weatherstripping soon. I also ordered tool covers for behind the seats from Zcardepot. They don't have the hinges. So they may not work for me... Since I don't have the old covers6 points- [2025] What Did You Do To/with Your Z Today?

My Zed club had it's last group drive for the year, yesterday. My car gal girlfriend was my navigator, as we drove the twisty roads thru Glen Valley in North Langley. Great day.6 points- My two swiss S30Z Fairlady Restoration build thread

Recently, I was able to obtain something rare, which I've been searching for five years, or so now. But let's start in the beginning. In 1937, Nissan registered a daughter-company called "Nissan Auto Sales Co. Ltd." as a sales division spin-off. In 1957, the same company registered the "NISSALCO" trademark, with the aim to develop and produce service tools for Nissan factories and workshops. They produced all kind of mechanical and electronic testers but also accessory parts for Nissan Car owners. Here is a picture from the Nissan Cherry assembly line, with a NISSALCO sign above every test bench: Today, the company is still existing, but under the "ALTIA" Name. In the early 70ies, they developed a Special service tool box for the Datsun 240Z sports. ST0929-0000. And yesterday, I finally got one, after many years of searching for it. The toolbox comes with a selection of Special tools for the 240Z. And this box came with a lot of extra tools inside. You can lift out the upper case, and then you have access to the lower level. Mine included also the Booklet that comes with it. So first, I had to get all the parts out and go through them. Luckily, i collected some of the Datsun / Nissan / Kent-Moore Special tools books over the years. And the box (even though without any part number or information) and some of the tools are also listed in the US-service manual: Sadly, I quickly realized that my purchase came with a lot of additional tools which do not exactly belong to the S30, but random Datsun's, and some original tools from the box are missing. It seems that the previous owner also recreated some missing tools. Overall, it's still a good starting point. After cleaning the box out, hammering the metal straight and fixing the locks. it started to look good. I wanted to keep the patina, but still clean up all the parts. so i gave them a quick wash in the parts cleaner: And then put the original parts back in: Assembled (some tools are not correct): And closed: The set also included this nice Nissan wooden tool box, with the lovely lock: I still have to figure out yet what this is used for, but i just love the looks of it: I'm also working on to restore the original manual that came with it: But it appears that the last few pages are missing and the back cover. But still better than nothing. It also has a very strange format, where each page is only printed on one side and then folded to have a print on both sides, which is a bit weird. That's it for now. I will try to keep finding the missing tools and pages. If you know something, I'm happy to hear from you. Expect some more tools related stuff in the coming days, but i also hope to work on the car itself again, in the next days. Stay tuned!6 points- Z's on BAT and other places collection

I just wanted to chime in, since I'm also a member of S30 World, a later edition, so not in the group photo with Takeo Miyazaki, which took place when the museum opened. However I am thrilled to have been asked to join in and represent the Australian part of the team, as mentioned Chris' goal is to ensure we have a global perspective on these cars and I've been the local train spotter in the Australian market for many years now, having got into my first S30Z back in the late 90s and joined this website in year 2000 I believe? I am also the owner of a couple of low vin # Australian delivered cars - which have their own unique differences. Even though I've been passionate about the S30Z for 25+ years, I still have things to learn, especially when it comes to cars delivered to markets outside Australia. I think we are all still learning, which is why the S30 world project and website is important, to help educate, discover and document. I'm also thrilled that through the restoration work Chris has spearheaded new parts have come to market to provide quality OEM-like reproduction bits and pieces (eg: fuel tanks and door seals just to name a couple). I was fortunate enough to see the quality of work first hand back in 2017, a local Australian had his car in display at the Nissan Datsun Nationals in Sydney. (attached photos). I've seen many 'restored' cars over the years and this was indeed top notch! Obviously not a 'factory style' restoration, but a superb finish none the less. The quality of finish achieved on cars completed since then has only improved! On a personal level, I feel the S30Z series have been greatly under appreciated for many years, however it would appear that more and more are starting to appreciate these cars these days and I'm very happy to see more cars getting quality restoration work performed at this level.6 points- The OG 240Z - Reanimation Project

6 points- The OG 240Z - Reanimation Project

6 points- The OG 240Z - Reanimation Project

6 pointsWait... I'm supposed to have straps under the seat bottom? So THAT'S what those stiff crusty things hanging down were supposed to be!!6 points- The OG 240Z - Reanimation Project

6 points6 points- The OG 240Z - Reanimation Project

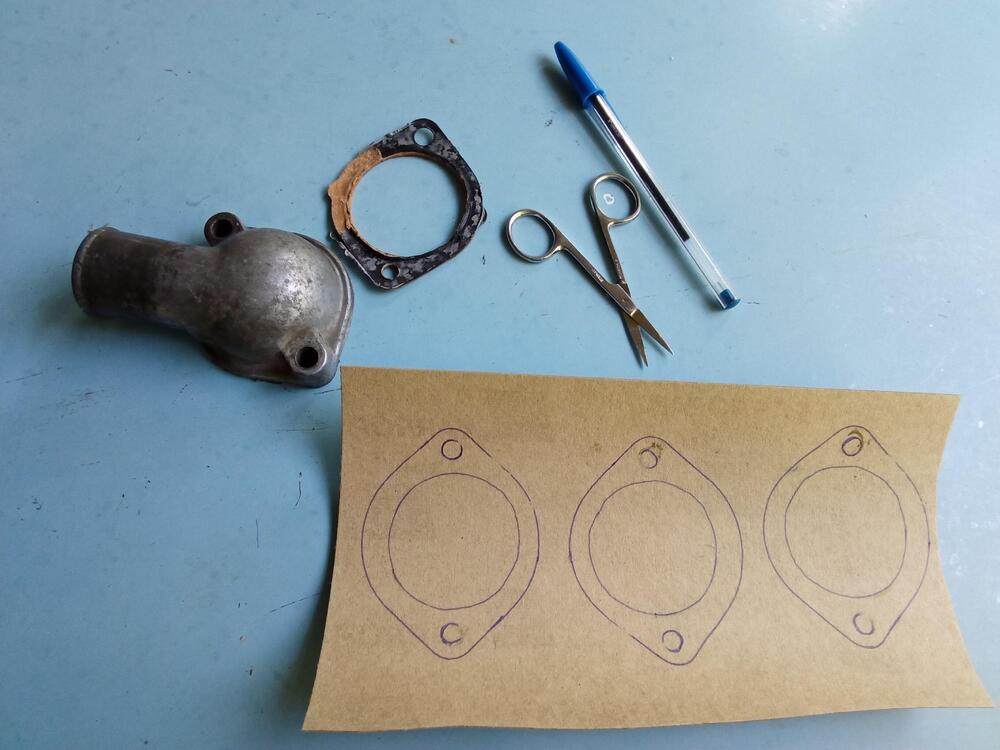

6 pointsTodays event... I put a160 degree thermostat in. Didn't expect it would help anything, and it didn't. But just for completeness, I had to. So cut some gaskets from sheet with the scissors that came from the first aid kit and the hole punch borrowed from the hotel lobby desk. Haha!6 points- [2025] What Did You Do To/with Your Z Today?

6 points- The OG 240Z - Reanimation Project

6 pointsThe way my insurance policy is with Hagerty's if it catches on fire I'm breaking out the weenies and marshmallows and enjoy the bonfire. But my luck some dumbass would stop and put it out before a total loss.6 points- After 8 years of setting I got my 240Z back on the road

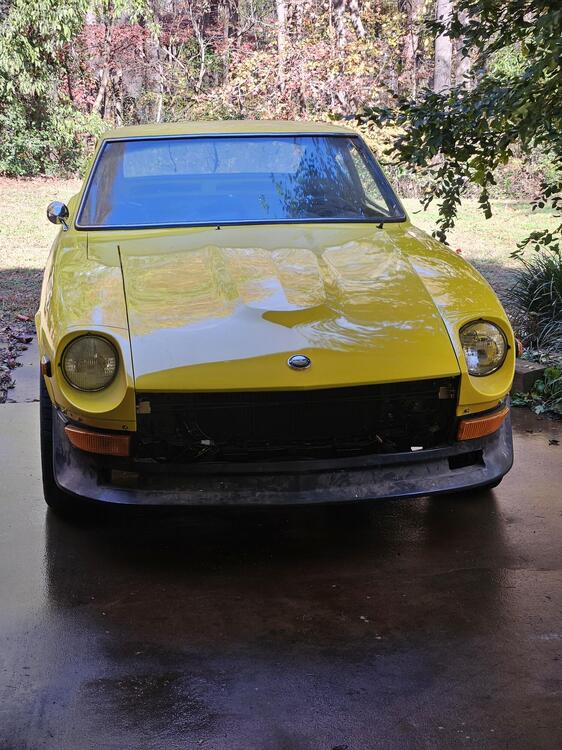

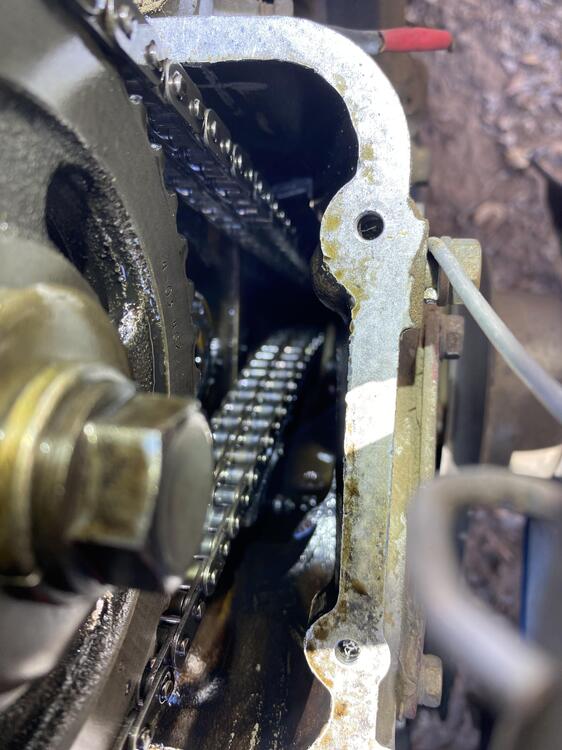

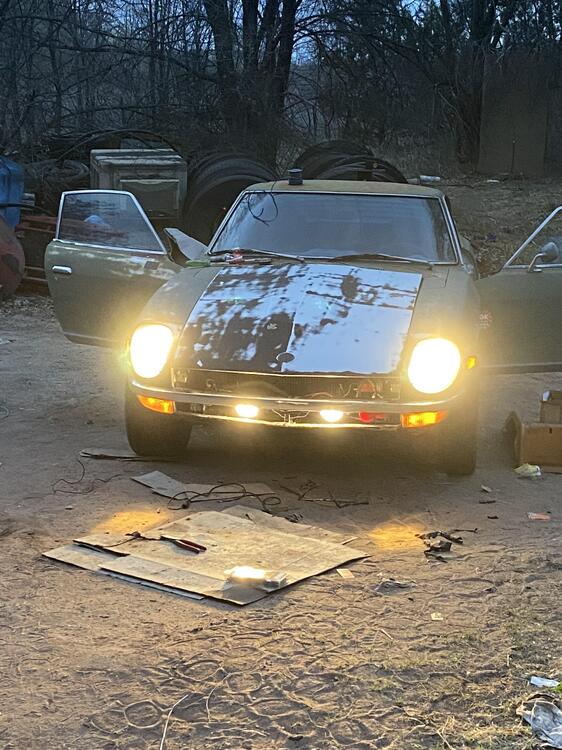

So just a little progress of working on my 1972 240Z that I’ve resurrected twice now since I’ve owned it from 2005 or so ..it’s been a long project and not perfect but it was my daily driver . This is where it sat for 8 years untouched next to my 1988 Toyota pickup in December 2024 All loaded up for the 1500 mile return trip in my 1986 f350 diesel I pulled from a field for 500 bucks a year earlier Once I got it home I got it running pretty easy but noticed an immediate problem in the form a rattling noise from the timing cover to discover a broken tensioner and missing bolts . After that issue was fixed I decided it was time to install my big brake kit I got from a junk yard 260z about 15 years ago .. don’t know who made the brackets but the calipers and rotors are from a 90’s corvette .. 12 inch rotors too ..don’t worry about the wheel studs they have been replaced since It also needed the carbs tuned As you can see they were way off plus I discoved the carbs were loose too ..explained why the erratic idle lol I just had to get a star road shift knob Radio was full or rodent crap and figured why not add a wide band afr gauge from auto meter in its place along with my driving light switch ..I still haven’t cleaned the marker off Also had to make my own headlight relay upgrade to run flosser h4 90/100watt ralley lights It’s an L28 with N47 head from a 1979 280ZX upgrades include 45dcoe triple Webbers . Msa 3 into 2 headers msa stage 3 schneider cam along with schneider valve springs Holley blue fuel pump . Kameari Racing distributor and fidanza light flywheel with centerforce clutch . Also running a single grove dampener . I will get the engine rebuilt in the future and get it up to 10.1 cr so maybe I’d get more out of the mods I have ..but still runs great and sounds amazing .6 points- Z Restoration Progam

6 pointsA little late jumping into this conversation. I have been "out of contact" on holiday which I do every so often going internet dark for a few days in my effort to get away from it all. Often, I travel to Europe but I just returned from several days in coastal Maine and that northern wilderness. We were hiking and boating. Reading up on this discussion, I thought I would chime in on some of the issues mentioned. Nissan contracted with four private restoration shops during the Vintage Z program. Pierre Z in Hawthorn, California completed by far the most restorations, however Classic Datsun Motorsports of Vista, California, Datsun Ally of Signal Hill, and Old Car Service of Huntington Beach were also involved. Datsun Ally and Classic Datsun Motorsports prepared two cars each. I don't know how many Old Car Service prepared. Engines were rebuilt and provided by AER Manufacturing in Arington, Texas as transmissions came from Williams Technology of Summerville, South Carolina. Pierre Z rebuilt the units for the first restoration only as Nissan contracted thereon. They were assembled units, crate shipped, including everything except carburetors, generators, cooling fan and hoses, and exhaust manifold to the best of my knowledge. Part management was coordinated through Pete Evanow of Nissan N.A. and there were documents related to car assessment, part orders, and quality control however these were internal project documents related to the management of the project cars and not released with any of the cars. I actually have part order documents for cars that were never restored. Concerning CAD plating: The yellow / gold coloring that we associate with "CAD" is a chromate conversion coating applied over the plated metal, yielding the familiar gold color. A similar appearance can be achieved with a similar chromate conversion over silver zinc which is far less toxic and not easily discernible from a cadmium base electroplate. Cadmium electroplating on its own is not yellow. I believe that what we see on cars today is yellow chromate zinc. True cadmium electroplating is not easily found or inexpensive. We all seem to call it "CAD" but that's probably a term we use for the color and not AS 9100 certified or ASTM A165, SAE AMS 2400 specification. Finally, Nissan N.A. didn't just decide to restore a bunch of 240Zs; they schemed up an ad campaign to keep the Z legend in North America alive while Nissan discontinued their current model Z with only the promise to deliver a new design some time in the future. The goal was not to create 'restorations' but deliver complete, running examples of the original car with 12,000 mile warranties. They had to rely on private repair businesses to accomplish their goal with a parts inventory that could not sustain the project. But they pulled it off! Cudos to the businesses and people who contributed to the effort. The cars are quite valuable now, and it is always exciting to see one because the story behind it is one of the best automotive sales campaign stories. Especially after the blunder of dropping the Datsun brand, I opine. So, I did the research project / compendium in 2005. I have a huge digital file of stuff as well as a fairly good library of literature. I have a vhs video that Pierre gave me in 200? that has Mr. K's visit during the restoration program. I don't have any printed , bound copies at the moment. I hear some interest for copies of stuff I have. I'm going to get some copies of the compendium made. Stay tuned.6 points- 1971 HLS30-14938 "Lily" build

6 pointsThe door latches I used Tail light chrome pieces. They weren't very flat. So I heated them slightly to reshape them. I did cause some wrinkling in the finish on the one that was pretty warped. I probably should have sent them back and exchanged them but for now it's fine Bought some washer to hold the trims on Installed Some butyl to hold the lens in The center post of the chrome is supposed to be long enough to go all the way through the back and get another star washer. The posts on my repops aren't long enough for that. So hopefully the lens don't fall out Felts for the bottom lens drains Shop dog More Belmetric Lights in place Finishers Badges, because everyone knows badges make cars run better!! ;)6 points- Restoration of BringaTrailer 240z - HLS30-35883

I was able to get everything back together on the car yesterday. The new yoke (with a new bushing in the back of the transmission) was a very snug fit. After double checking I torqued everything, I was able to take the car on a test drive. What a big difference! I got up to about 80 on some interstate and the severe vibration, which previously could be felt with a hand on the transmission tunnel, and seen in the blurring rear view mirror, was gone. Now, I can get back to the small list of things that I have to do to finish this car: install inside rear tail light trim panel install front right kick panel clean and glue in tool compartment liners repaint tail light trim panels (for better color match) install NOS glove box hinge/inside panel install rear hatch trim panel repair and install factory radio, or install guts of a new radio in the old radio case6 points- SN 00042 Restoration; The Older Twin

6 pointsGuess I'll put it here as this is, at least to this old buzzard, the path of least resistance After almost 190,000 miles and a bit of bearing noise I decided to give the 5 speed in my 78 280 the business and @ the same time address all of the related issues. At the risk of glazing the eyes of my audience I promise to be brief. I had the rear engine plate powder coated - yes, I know it was clear zinc plated from the factory but I wanted to see what my very excellent powder coater could do and the results are very satisfactory - removed 4 pounds from the stock 24 pound flywheel, had the now lightened flywheel balanced along with a new pressure plate, replaced the rear engine seal, clutch assy - used the Exedy set for probably the 100th + time in my career - flywheel and pressure plate fasteners, ALL of the trans bearings, 2nd and 3rd gear syncros, seals and gasket and had all of the related fasteners, etc. zinc replated. This past Sat I drove the 350 mile round trip to Import Carlisle - touched 100 MPH for a couple of seconds - without a hint of concern. I got those trans parts I could from Nissan - yes, I know there are some cheaper alternatives but I like the guys at my fav dealer. Those bearings that are NLA from Nissan I got from a company in Japan, Amayma. They, Amayma, provide excellent service and excellent prices for parts in the original Nissan packaging. Way back in 1971 the dealer I was working for sent me to Datsun trans school. The school held @ Datsun eastern headquarters in Secaucus, NJ. The dealer provided me with a NEW, just off the boat, 510 2 door for transportation. Yes, a new 510 2 door was capable of an indicated 100+. We were provided lunch at what was, I'm confident, a mob owned restaurant. Our instructor told us we could order ANYTHING on the menu but if we wanted lobster we had to give one day notice. Those were the days.6 points- 1970 Wiring Diagram

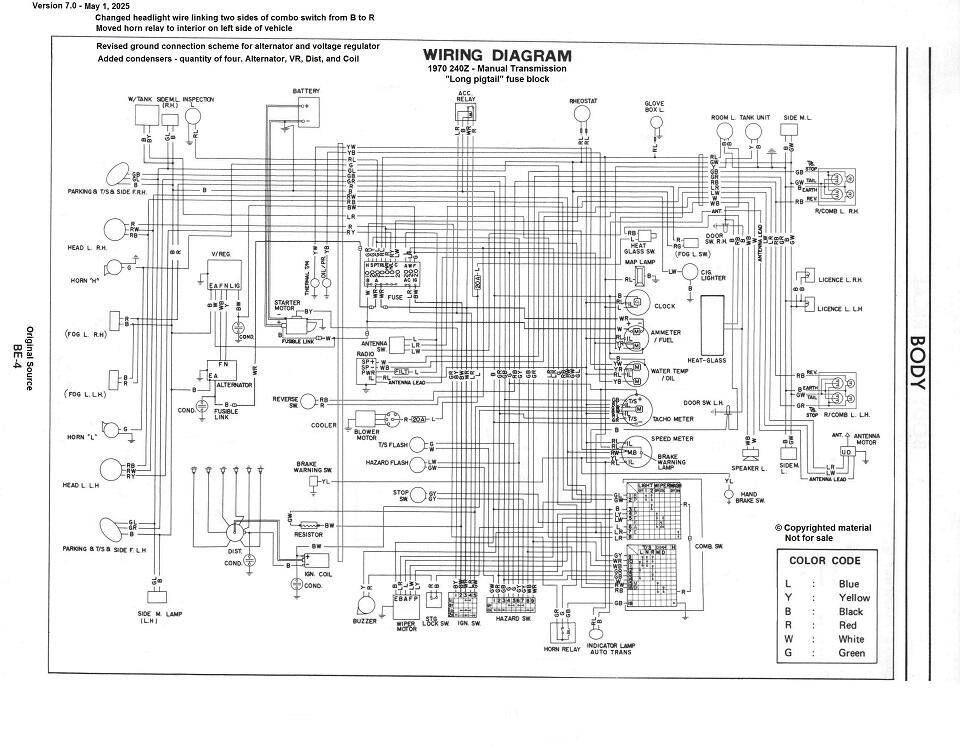

6 pointsHere's the latest wiring diagram. I moved the horn relay to the interior side of the firewall. It was previously shown out in the engine compartment, but in reality it's actually located on the left side of the interior near the driver's left knee and the hood release pull. Changed the way the alternator and voltage regulators make connection to ground. And made a couple of minor wire color changes. And lastly... Thanks to the help from the folks here, it now has condensers. <V7.0> _obvious 240Z Wiring Diagram 7.0.pdf6 points- 1973 Rebuild

6 pointsI am very tired and sore. What I thought was going to be a three day job ended up being two weeks… because I am a perfectionist. 😕 The installation of the left door window was no big deal, but I wanted the glass to be as clear as I could get it, so I spent six (!) days working the scratches out of what was a B+ window when I pulled it out of a wrecked car a year ago. I used a combination of diamond polishing pads and cerium oxide, which works well, but there is a learning curve. The right side should only take a day now that I know what I’m doing. It’s now a solid A grade, but I came a little too close to the Nissan etching, so that’s less crisp than it should be. All told there are two 1/4” scratches and some light swirls that I couldn’t get out without risking distorting the glass. Not bad. Acceptable I guess. Installation was not hard, although I should have brought a second set of hands. I have some alignment issues with the rear corner sticking out and not sliding back enough without help from outside, but I don’t feel like dealing with that right now. New seals, new hardware, and tons of grease.6 points- Restoration of BringaTrailer 240z - HLS30-35883

The "grocery getter today": Walking towards the car with my grocery haul, I laughed out loud as I gazed at the car. Though not quite as small as a Miata, the size of these things is quite laughable. Pictures of it by itself (purposely parked far away from others) don't reveal its compact size. But, put it next to nearly any modern vehicle and the small size becomes very apparent. My tire diameter is a little smaller than stock. So, even though I have a "red gear" speedometer drive to match the 4.11 rear end ratio, the speedometer appears to be off on the high side. I will check it vs. actual speed with my phone/GPS soon. For now, I am just trying to keep from being freaked out while I drive it around. For the first 15 or so miles, I have been pretty anxious, thinking of all the things that could go wrong. On the way back from the grocery store, I started to feel "at home again". The exhaust note is quite aggressive, and loud... and that is a good thing. 🙂 It has been 9 years since I have driven a 240Z, albeit the last one was my more "track focused" 240Z, which is an entirely different beast. I still have many things to finish up, some of which include: figuring out what to do about putting a speaker in the stock (rear, left) location. This is holding up putting the left side interior trim panels in place. decide whether to put the factory radio in the dash, or install a blue tooth compatible "Retrosound" unit. troubleshoot why interior fan is not functional install glove box door spray paint and install tail light finisher panels and rear license plate light spray paint and install front grill install steering wheel horn hub/garnish install luggage straps cut jute for the front floors install front right kick panel (I am still evaluating right door fit/alignment) Install storage compartment liners - glue to body Place jack and tire stops in storage compartment6 points- Restoration of BringaTrailer 240z - HLS30-35883

I have installed the windshield - this time with the stainless trim! It's not fully in place as it should be - it sits about an 1/8 of an inch more toward the passenger side. However, that will auto correct when it sits in the hot sun for a bit. This third windshield seal was very flexible which made a big difference when installing the stainless trim pieces. And so far, this second windshield has not delaminated in the corners like the first one did. The other part I was waiting for was a replacement brake booster push rod. With its arrival last week, I was able to complete the rebuild of the brake booster and to get that installed in the car. Using a vacuum tool like this one - I was able to build vacuum to 500 mm Hg by connecting it to the hose from the booster and waiting the 15 seconds specified in the factory workshop manual to confirm it was within specification (did not lose 25 mm Hg or more in 15 seconds). With these two things completed (brake booster installed and windshield installed), I was ready to take the car for a brief test drive. The car now has 15 miles on it 😉 During that brief drive, I noted that the brakes are not 100% yet, and the exhaust was vibrating against the rear apron at idle. When I got back, I put the car back on the lift. I found a bit of brake fluid on the front right caliper, so I quickly cleaned that off and went around to all of the brake line fittings and ensured they were all tight. I will need to bleed the brakes again to ensure all air is out of the system. For the exhaust, I simply loosened the band clamp that holds the muffler to the tail pipe and moved the muffler forward 3/4". One of the things I was worried about was the differential. After all the trial and error with shimming and the custom work to rebuild it, I was worried I still didn't have the gears meshed properly and it would make a lot of noise. I am happy to report that I don't hear any noise coming from it. It is super quiet even. I am glad to have these two things that were holding me up out of the way!6 points - Happy Anniversary To Me!

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

.thumb.jpg.2541638339411e470782affaa6156b97.jpg)

.thumb.jpg.7975d9e3eef9ae1c9905638c821c3105.jpg)

.thumb.jpg.31acc02f0a3362f6aa428d70b7c93d45.jpg)

.thumb.jpg.d1865eaedd434fca9391d0ca9e691b1a.jpg)

.thumb.jpg.c45fc70dd36fba0a1fd694599c15fcd6.jpg)

.thumb.jpg.cefc97e6fc5f3f155523ae20229f3edb.jpg)

.thumb.jpg.eac1804e34f58e93433fef497ce53001.jpg)

.thumb.jpg.2031df026611687fc1d90e8e1b692d82.jpg)