Leaderboard

-

conedodger

Free Member89Points11,548Posts -

siteunseen

Free Member35Points14,981Posts -

Zed Head

Free Member25Points18,944Posts -

SteveJ

Free Member18Points9,615Posts

Popular Content

Showing content with the highest reputation since 06/17/2025 in all areas

-

Datsun 240Z Ashtray Snuffer Plate Reproduction In Stainless Steel

eBay UKDatsun 240Z Ashtray Snuffer Plate Reproduction In Stainle...Datsun 240Z Ashtray Lid Insert / Cigarette Snuffer Plate – Reproduction Part High-quality reproduction of the original Datsun 240Z ashtray snuffer plate, designed to match the look and fit of the f... Datsun 240Z Ashtray Lid Insert / Cigarette Snuffer Plate – Reproduction Part High-quality reproduction of the original Datsun 240Z ashtray snuffer plate, designed to match the look and fit of the factory part found in 1970–1973 models. Precision-cut metal complete with M3 bolts and nuts for easy installation. Fitment: Datsun 240Z (1970–1973) Material: Stainless steel Slotted snuffer design, includes M3 bolts and nuts Ideal for restoration projects or replacement of missing, broken or corrodedl parts7 points

-

Z's on BAT and other places collection

If a sermon could save even one soul it would be worth preaching. I think you'd find - if you gave it the benefit of the doubt - a smattering of eager listeners in "this crowd" who would appreciate the chance to hear what you have to say. If we don't deserve it, then who does? You might look at the current exchanges on this forum and see members eagerly conversing with what appears to be an Artificial Intelligence 'bot, but over the years some of us have drilled pretty deeply into the story of these cars, the people and circumstances behind them and into their very fabric. I can think of few other open source platforms where this has been made available in the English language. Hopefully (!?) much of that still exists here and is - with effort - searchable for those who are curious and/or passionate enough to know. At the very least, put it out there before you can't. Pro Bono. Thanks.7 points

-

1971 HLS30-14938 "Lily" build

5 pointsThe door latches I used Tail light chrome pieces. They weren't very flat. So I heated them slightly to reshape them. I did cause some wrinkling in the finish on the one that was pretty warped. I probably should have sent them back and exchanged them but for now it's fine Bought some washer to hold the trims on Installed Some butyl to hold the lens in The center post of the chrome is supposed to be long enough to go all the way through the back and get another star washer. The posts on my repops aren't long enough for that. So hopefully the lens don't fall out Felts for the bottom lens drains Shop dog More Belmetric Lights in place Finishers Badges, because everyone knows badges make cars run better!! ;)5 points

-

Matching Rubberized Undercoating

4 pointsCircling back as I just wrapped this up. My air compressor was having some issues and wasn't very consistent, so I had to do some repair work on that. After getting that fixed, spraying a few more test shots it looked a lot better. Ended up taping up the underside of the car and plugged the frame rail fuel hose pass-through with a piece of fuel hose with some tape wrapped around it to block the holes. Ended up spraying 3 coats, waiting about 10 minutes between each coat and I'm very happy with the results. It ended up being quite close compared to what was there.4 points

-

Twin safari gold Z's. The build and the build that inspired the build

Built my custom 86 Z31 300zx over 4 years. It took best in show from Pit&Paddock/Meguires at SEMA 2021. The inspiration for my build was the 240z my dad and I restored together. A car that I found as a teemager back in 1993. My dad finally acquired his last dream car, a white on tan 993. Only problem was, he ran out of garage space. He was planning on selling the orange car but just couldn't bring himself to let it go. So he made me a deal I couldn't refuse on the safari gold car. Amazing to have both cars together!! " " " " " " " " " "4 points

-

Looking for Turn Signal Switch Upgrade

Thanks Guy, but I am disinclined to follow someone else's work in this case. In his ebay post I noted that he "modified" plastic connectors and the metal base. With all of the switches I have refurbed I have not yet found a need to modify the OE components - sometimes replaced with new or from the parts bin but never modified.4 points

-

Twin safari gold Z's. The build and the build that inspired the build

4 points

-

Z's on BAT and other places collection

You've pretty much answered your own question there. And when it comes down to it, we'd have to judge it as a success in those very marketing terms let alone anything else. The press loved it. The project caught the imagination and support of influential figures in the North American Z 'scene' - including the kind who insisted it was a first for a major manufacturer (it wasn't) and "unique" in the auto manufacturing world (it wasn't). Those same figures still vaunt it today. We've certainly discussed the topic here on classiczcars.com many times over the years and our fellow member @26th-Z wrote what I believe is the definitive essay on the VZ cars. It was - when all is all said and done - a big deal in the story of the Z car's mid-life crisis. But as is often the case, the hype and commentary from offstage created unrealistic expectations. The misleading term 'Factory Restoration' was thrown around a lot and many swallowed it whole, including members of the specialist press. The VZ cars often get judged as though they were intended to be 100% factory correct concours restorations when that was clearly never the case. You can see the same thing happening in the current BaT auction. LOL. Another bunch of answers to your "why are the Vintage Z valued so highly?" question in there. It's the kind of people appearing in that video - and mentioned in it - who are part of the hype. High profile figures in the old Z car world, but often too the Typhoid Mary-like spreaders of bad information. Whilst looking in the engine bay of a VZ car we get the words 'Nickel' and 'Cad' plating thrown around (its mostly Zinc...) and a false story about the commissioning of re-pop braided hoses (Nishi san of Revive Jalopy in Japan was responsible for this and for many other previously unobtainable parts too). We even see a modern fuel filter pointed at as though it is some kind of ancient relic. Some typical 'Mr K Lore' thrown in for good measure when discussing early cars/chassis numbers. Larry Chen asks "why is it that the US got the early cars and how come Japan didn't get the early numbers...?" and Jaffe's answer talks about the '240Z'. Japan did get early cars (they got them earlier than the US too...) but the problem here is the congenital misconception that the 'US 240Z' is something over and above the whole S30-series Z family as conceived, planned, designed, styled, engineered and produced before the end of 1969. To the point that anything else is some kind of afterthought. We get Katayama's "PUSH" related as a one-man quest to get 'his' project made rather than the more realistic scenario of him lobbying for influence on something that was already happening. Apparently Mr Carl Beck ('Z car encyclopaedia') "can tell you how many went to England, Australia and its all very limited...", but there's no mention of Japan in their 'Z car' story. You can look at pretty much any volume - and non-volume - selling sports car of the 60s and 70s period and see the same story; volume sales in the USA. But I've yet to see any Triumph, Austin-Healey, MG or Jaguar being vaunted as 'Made Expressly For The USA'. VW shipped just shy of 400,000 Type 1 Beetles into the USA in 1968 alone, so 'Made For The USA'? Mainland USA was the biggest single potential market for just about any product of the period concerned, but I would like to credit at least some US consumers as being sophisticated enough to see through all the "we made this for YOU" type sales slogans. So, why are the Vintage Z cars valued so highly? It's in large part due to the influence of the kind of people who had eight of them, and sold six of them to somebody who now has eight. Larry Chen will make a video about them! People listen, and look up to, movers and shakers like that. Our old BaT friend Larry Stepp (he's a BIG fan of the classiczcars forum) made a prediction the last time this current BaT auction VZ car was up for sale. He said it would be worth 250k USD in a few years. There's the hype. It's not so much to do with the physical details of the object (which is not too shabby, to say the least), it's the perceived kudos and status within a fairly small cohort of people who are looked up to as sooth-sayers and mystics. Buy "one of the 37" and - hey! - maybe you'll even get the pleasure of putting the hose clamps on 'the right way round'...4 points

-

Is anyone there?

4 points

-

Guy's wanting my 240

4 pointsThat's a midlife crisis screaming out loud car. I'd end up wearing shoes without laces. 🤪4 points

-

Gas Tank removal problem on my 72 (12/71) Z car

Here's a way to clean your old tank if you ever decide to. 🤣🤣😁3 points

-

Looking for Turn Signal Switch Upgrade

Context? Where did that come from? It is Saturday night of course... 🤩3 points

-

Looking for Turn Signal Switch Upgrade

I'm older than that and I still work properly! Sometimes...Sort of...;)3 points

-

Looking for Turn Signal Switch Upgrade

There's some BS going on here. 13Ax14V=182W. I'm not sure whose backside produced a 13A figure. There are 2 (two/dos/zwei) 23W bulbs and a 3W bulb (on the gauge) in the circuit. Please invite the person who gave you that response to come here and show the testing. Until proved otherwise, I posit that someone is covering up for shoddy work. I am interested if someone can make me eat my words. I'll see if I can set up my scope with ammeter to look for transients that even come close to 13A3 points

-

New Source For S30 Door Seals

3 pointsI finally got around to installing my s30 world seals. Its definitely something you dont want to Rush and should bend the U shape carriers into semi final form first. And be careful as you can not to rip the top corner...mine is on and im as please as can be. I've tried every other seal out there and slam slam...not with these im so happy with them. Amazing product!3 points

-

Twin safari gold Z's. The build and the build that inspired the build

3 points

-

Twin safari gold Z's. The build and the build that inspired the build

Yep…..Had to make a space for my new toy…..I always thought the 1995 911 was the most beautiful Porsche of all times. IMG_8935.mov3 points

-

Z's on BAT and other places collection

If it's possible, try contacting the people who placed these six figure bids and ask them? I can understand the emotions behind an auction, but there's got to be good reasons why these cars are selling in the high digits. In my opinion, this kind of money is only spent by people with the cash to do it. Unless they have inherited the money, they are likely very smart with their life choices and will have a valid reason to throw six figures at such a car. It typically won't be a whim and they will not do it unless there's some kind of investment value. BTW, "value" is a subjective term and doesn't always equal money. ;)3 points

-

Z's on BAT and other places collection

About this Vintage Z - As I recall - this one first showed up for sale about 20 miles North of me. New Port Richey or Holliday Florida. A friend of mine went to look it over, and reported that it was very poorly cared for. The next time we saw it, was its first sale on BAT. My fiend remarked that it had been very well detailed for that sale and looked 100% better than his personal inspection. Now we see it again, with an owner that put some significant funds and I’m sure elbow grease into it - to bring it up to better condition. Will the customer modifications hurt its market value? Not as much as the current market itself, the mod’s might hurt it a little as most collectors don’t want to mess with fixing anything.3 points

-

Is anyone there?

3 points3 points

- Nice Brochure

3 pointsWhile at a car show this past weekend, had a very interesting conversation with a gentleman. His parents opened a Datsun dealership in Moose Jaw, Sask. The year was 1966, he said that the family home was on the same property and he grew up working in the shop. He remembers the day the Datsun Training trailers pulled into the yard and all of the mechanics spent a week going through the courses. He gave me three of these plastic bags, he says he has lots more Datsun stuff . I am working on getting a chance to go shopping through his collection.3 points- Early/late thermostat housings

3 points3 points- Datsun 240Z Ashtray Snuffer Plate Reproduction In Stainless Steel

As part of the 4th of July celebrations I am offering a sensible discount to any of the reproductions I make- make a sensible offer A link to my ebay store https://www.ebay.co.uk/usr/katodfa2 points- Happy 4th of July!

2 pointshttp://www.zcarblog.com/wp-content/uploads/2023/07/7B1C3893-E7E1-4082-978E-03E86971037F-1024x1024.jpg From all of us at Z Car Garage we hope you have a wonderful 4th of July weekend! Long Live The Z Shown above in Red, White and Blue are our clients: CJ’s 1971 Datsun 240Z Mike’s 1970 Datsun 240Z Rob J’s 1971 Datsun 240Z http://www.zcarblog.com/wp-content/uploads/2022/07/bee20d36-c3b0-4195-88bf-ab197222412e-1-914x1024.jpg View the full article2 points- Is anyone there?

2 pointsNo sir, that's America's favorite Dad, Sheriff Andy Taylor played by Andy Griffith. You should stop what you're doing right now and start watching episode 1. 😁2 points- 1973 Rebuild

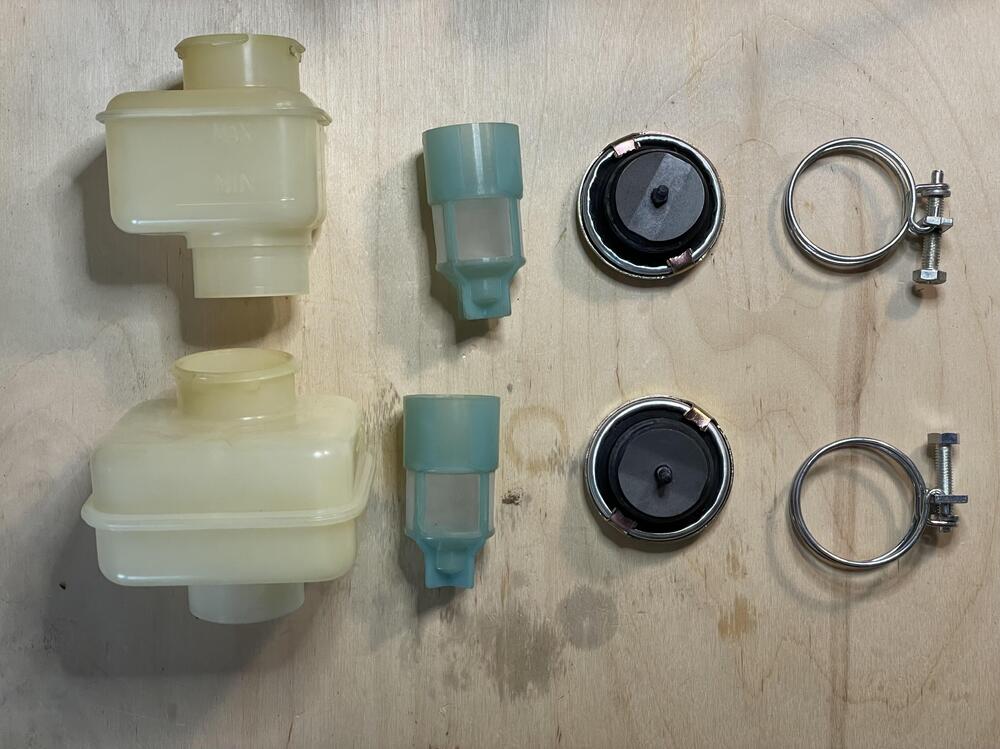

2 points280ZX Brake MC is ready to go! I tore this apart several years ago thinking it would be a short project, but the rebuild kit I had turned out to be for the one made by Tokico (large perforated disc residual valves) and this one is made by Nabco (small rubber duckbill residual valves, see below). I had messed around with trying to rejuvenate the reservoirs. I had read you could cover it in a solution of oxy clean and hydrogen peroxide gel under UV light for 24 hours and it would take the yellow out. It lightened it up, but they’re still clearly yellow. Super clean, though. I also did some chemistry on some of the hardware. The bleeders and reducers for this thing are not common sizes (the reducers are m16x1.0 to m10x1.0) and after two weeks of searching for replacements I gave up and decided to try chemically coating them. I didn’t want to do the hardcore hot bluing or zinc methods because of the chemicals, so I used the rust bluing method. Basically, you soak them in white vinegar to strip off the rust, zinc, and anything else on them. Then you paint them with a paracetic acid / salt solution (8 parts hydrogen peroxide:1 part white vinegar + as much salt as it will dissolve). Dry it with a heat gun and throw it into a double boiler. You’ll see the rust turn black, which is when it turns into iron oxide. Buff it with steel wool and repeat until satisfied, then soak for 24 hours in motor oil. They came out okay. I was hoping they would look more like the pistons, but this is what they look like after four rounds of the process, so it’s going to have to be good enough. Fingers crossed that they don’t just immediately corrode. You could also do the phosphoric acid version (cold bluing), but this makes a harder coating of iron oxide. Then I just had to hone the cylinder, flush it with 91% alcohol, wipe it out, and reassemble. I kept the Tokico 240Z reservoir caps since I didn’t wire the car for ZX caps (PN: 46020-U6701) with the fluid level sensors and don’t have the metal (PN: 46020-K2401) or plastic (PN: 46020-N6000) Nabco caps. Maybe later if I can find a set for less than €53.40. It looks pretty good after test fitting it. I’m waiting for a dust cover and O-ring in the mail, then I can install it and bleed the brakes.2 points- The Waive

2 pointsI've received several waves this year from motorcycle riders when I've been driving my Z. I'm not a motorcycle rider, so I haven't tried to respond "in kind" (and it might look a bit odd coming from the driver's door of a car), but I've given a friendly regular wave back. I definitely saw it as an honor (to the car), and was happy to see it in each case. I'm sure we all get lots of waves from other classic car drivers, which I'm also happy to receive! Yesterday, being Canada Day, was a big day for that!2 points- ITM Piston Rings

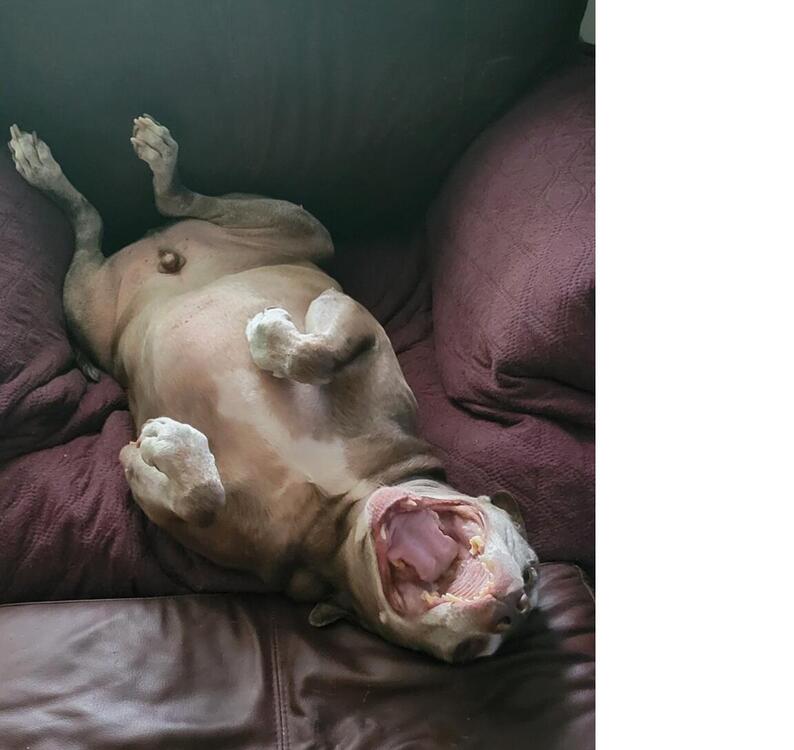

2 pointsNot so much trained but he does what he wants and gets what he wants I guess by just paying attention. He's the reason I get out of bed, his name is Rolex. I know what he wants and he knows what I'm about to do and runs and hides under the bed. Hates baths and toenail trims, cleaning his big ears are a weekly fight too. But I can't imagine my life without a good dog. So yeah I guess he is trained but I didn't do it, he did.2 points- Is anyone there?

2 points- ITM Piston Rings

2 points- ITM Piston Rings

2 pointsI've used Hastings twice and didn't run into any problems. My dog has started eating those gummies all the kids are raving about. Now he just lays around and poots and then laughs about it.2 points- ITM Piston Rings

2 pointsHi Site…..When installing new pistons and rings in an expensive rebuild, I want to feel confident that when I squeeze those pistons in the bores, they are perfect. The ITM pistons are awesome. When installing rings, I have found that the Total Seals oil rings mate up so easy that I can sleep at night shoving the pistons into the bores…….just me. I’m sure that ITM oil rings and Hastings will work, but I just never felt like I had them installed correctly….at least not in my mind. An extra $200.00 for top quality rings always seemed worth the investment…..whatcha think? BTW How’s your dog? Regards Guy2 points- Ads attacking!?

2 pointsNever mind. I erased my internet history and the problem went away. Didn't know that "cookies" could do that. I think I had clicked on something by accident. Back to original programming...2 points- Z's on BAT and other places collection

I like stock cars but I also like modified cars. I like it when hybrid cars use a driveline from the same manufacturer. If I didn't have so many projects I would consider taking that one on...2 points- Is anyone there?

2 pointsLol, I think it doesn't matter what car we drive. What matters is that we all like this culture2 points- rear clunking noise '76 280z

2 pointsHi guys, I replaced the mustache bar bushings and re-torqued my rear strut insulator lock nuts. I didn't notice any play there when the springs were compressed. The good news is that the clunking noise is gone. Replaced the master/slave clutch cylinders/hydraulic hose. The old ones showed some internal brake fluid leakage. No more grinding while shifting into reverse. The clutch fork moves 12.5 mm (half an inch). The pedal is at 8 in, 15 mm of free travel before the slave starts pushing the rod. I searched this forum and someone mentioned that the 15 mm is a good number for a fork throw. I am guessing if mine was too short to disengage the clutch disk, I would have heard/felt it. Thanks to all who helped with the diagnostics!2 points- Guy's wanting my 240

2 pointsIt's a small car! I will get some nose to nose pictures with my 240. That dealership is only a mile from here. Here's my offer of his for mine, no response yet but I'll leave that on the table for ONE WEEK!😁 https://www.nissanofgadsden.com/used/Porsche/1988-Porsche-911-bd11c7e8ac181b91072054cb1839c5ba.htm2 points- Is anyone there?

2 pointsDon’t worry Ji-hye, I drive a Porsche as well and they haven’t treated me bad…2 points- Just Another Damned Z Car Project Thread

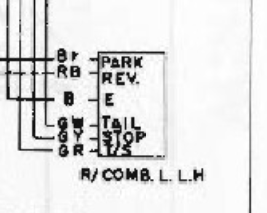

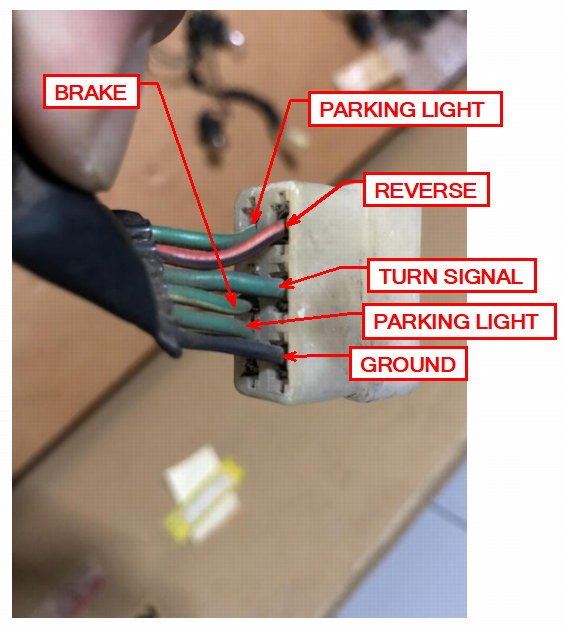

I had the weirdest accident! My truck was parked in my driveway. The instagram model across the street was parked in her driveway. Nobody in either truck. My daily is a 2024 Tacoma TRD Off Road. Hers is a 1998 Ford Ranger. Her truck popped out of gear rolled out of the driveway, across the street, up my driveway and in to the front end of my truck. $3000 damage, all cosmetic. The only thing my wife says is “only you could get hit by a damned instagram model!” My rental is a Nissan Rogue. I am struck by how much better the transmission feels!2 points- Euro / JDM taillight wiring

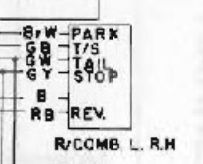

2 pointsThe 72 FSM has the colors. In @kats connector it does not show a Br or BrW wire. It shows two GW. This may be the correct orientation:2 points- Is anyone there?

2 pointsAnything to help another gearhead! Rust areas are the most important hidden item on these old cars.2 points- Datsun 240Z Ashtray Snuffer Plate Reproduction In Stainless Steel

Thank you Mike. If anyone from this forum wants one I'm sure I can arrange a sensible discount. Because the cost to ship to the USA is quite expensive if a few people wanted to club together i can send in one go.2 points- 1970 Wiring Diagram

2 pointsOh, I totally get it and agree completely. It's just odd that Datsun put out a document that seemingly delineated the timeline. Sounds like they were trying to differentiate between the two and put a stake in the ground as to "when". So here's a thought... Maybe that VIN of 21001 would be better interpreted as "We've been making changes over the past couple months, and as of VIN 21001, here's a list of what we've changed so far. Moving forward, all the cars will have these changes incorporated." Maybe that's a better way to think about it instead of "As of this VIN, we will be making all of these changes from this point forward." and changing all of them overnight at that VIN.2 points- 1973 240z Custom Wiring From Scratch

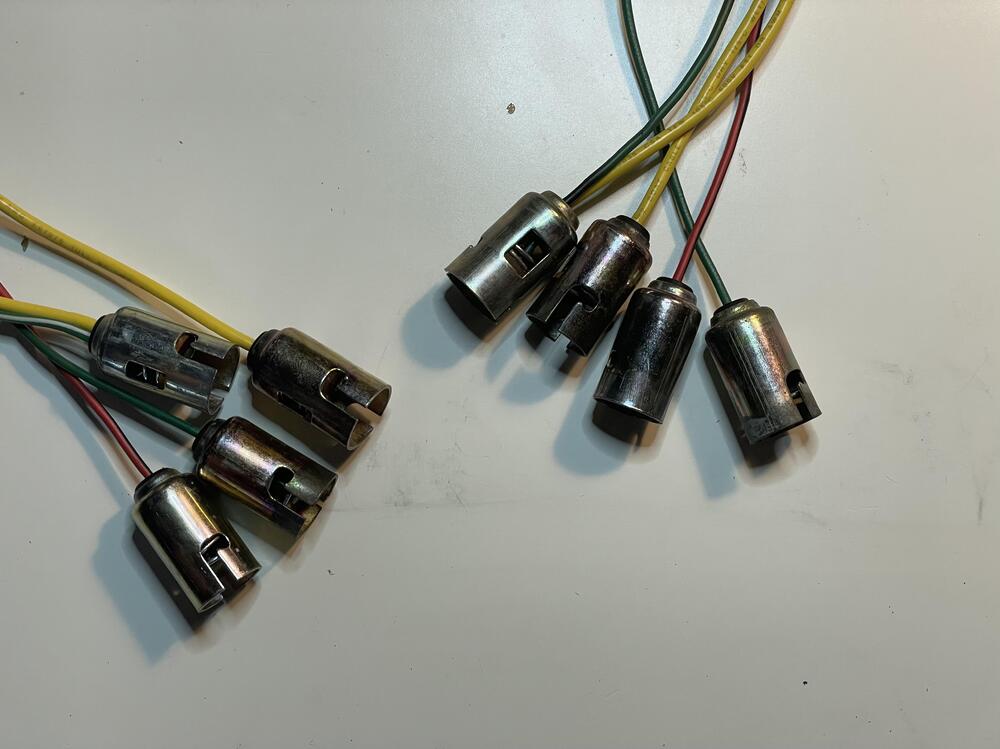

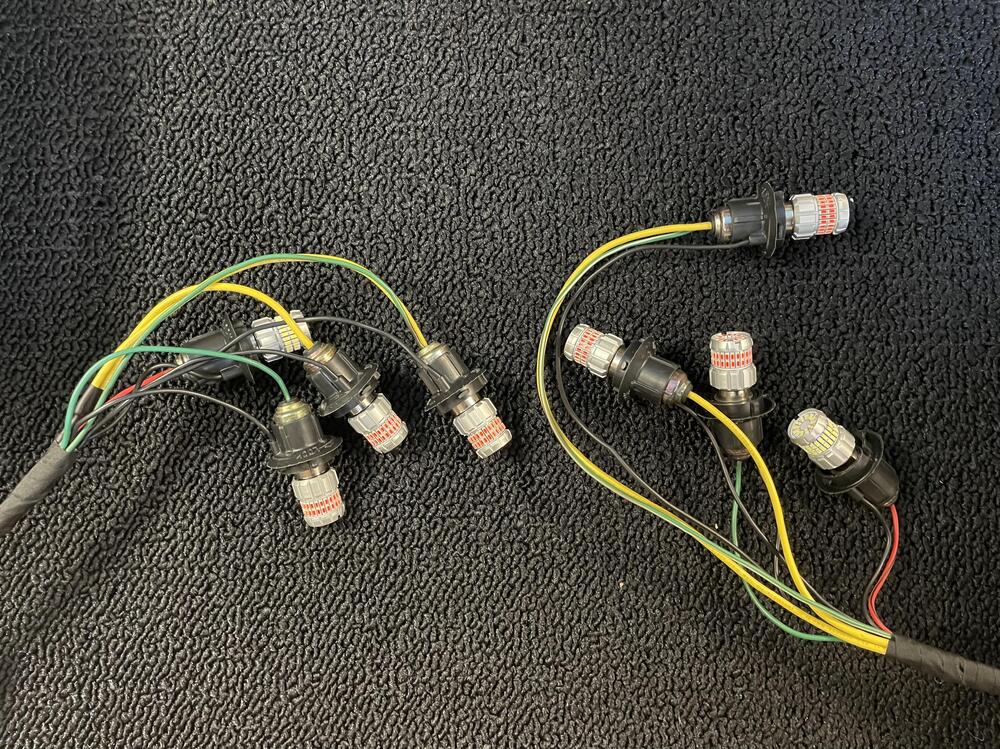

2 pointsQuick one today. After working out some kinks in the wiring (thanks @SteveJ) I’m nearly done with it. I refurbished the wiring for the tail lights this week. I’ve always planned to rework the arrangement to be more like (but not exactly like) the euro tail lights. I’ve read a ton of stuff about these cars getting rear ended, so I wanted to make it as clear as possible that I’m braking. I still plan to add a third brake light, but I think this is substantially better than the original US tail light configuration. Driving lights are the outside top lights only. IMG_4744.mov IMG_4745.movTurn signals are the outside bottom lights only (thanks to @w3wilkes for the flasher recommendation). Brakes all of the top lights. Now I have to figure out what I’m going to do with the front turn signals. These LEDs are so bright that when the driving lights are on you can’t tell they flashing from more than a couple feet away. I’m wondering if there’s a way to make it cut power to the driving light wire only when the turn signal is working.2 points- 1970 Wiring Diagram

2 points- Let's show vintage racing pictures. I'll start.

2 points- Engine rough running - at wits end

2 pointsThat's the same as mine, door guards and all. Your paint looks a lot better though as mine has never had a respray. Yours's is my good vs bad comparison.2 points- Parts for Sale: Distributor replacement magnet

I accept paypal. at chaug@bis.midco.net. 30.00 for the bearing retainer that goes in the breaker plate. I make them for the 74-78 electronic pickup distributors and for the 79-83 matchbox distributors. Both come with 6 new ball bearings 35.00 for a stator magnet. 60.00 for both as most distributors need both the retainer and the magnet. Free shipping to lower 48 USA I will know what the money is for when it is sent to paypal. You can also email me, or text me at seven zero one-471-fifteen thirtyfour.2 points- Engine rough running - at wits end

2 points- Engine rough running - at wits end

2 points@dutchzcarguy those are funny! The Richard Pryor baby is my favorite but it's a little coarse for all members. Héy Site, that picture reminds me of those vid's about the farm from Jeremy Clarkson, diddly squat farm.. (on Youtube) where toddlers play the rolls of all the people in the series!2 points - Nice Brochure

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.