View Advert

RB25 240Z

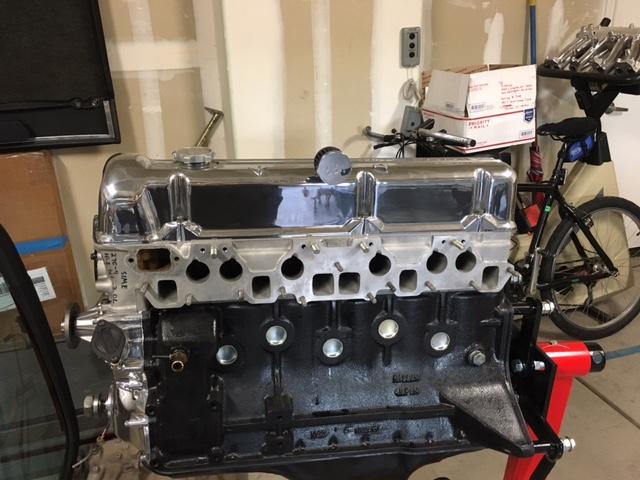

Fully restored and modified '72 240Z in excellent shape. I have owned the car for the past 10 years and have rebuilt it from the ground up including a down to metal professional paint job. The car is turn key and ready to go for anything. Too much to list and receipts for almost everything going back to the 1970s with the original owner including log book, manual, warranty info, etc. The engine is a freshened up Series 2 RB25DET with just over 400HP with all supporting modifications (fuel, turbo, coils, etc.) new and professionally installed and tuned on a dyno with a PowerFC. Even the check engine light is functional.

Suspension is a complete custom coil-over setup with all new urethane bushings, oversize disc brakes, MSA sway bars and OS Giken LSD. The chassis was stiffened and setup by the late John Coffey at Beta Motorsports.

Interior is custom two tone black/brown with Recaro SRD seats and a properly installed rollbar with DOT/FIA approved 4pt harnesses for both driver and passenger. Dash is redone and contains custom Speedhut gauges in all factory positions.

Aside from below, during the build most bolts, tabs, etc. were replaced with new stainless. Additional pictures located here: https://imgur.com/a/ZTWmMCw

Suspension/Brakes/Chassis:

Adjustable coilovers with full camber adjustment welded in

Wilwood oversize 4 piston front disc brakes with upgraded master cylinder and brake bias

Silvermine Motors 2 piston rear disc brakes with e-brake

Steel braided brake lines

Panasport 16x7 wheels with Bridgestone Potenza RE71R tires

MSA sway bars and urethane bushings all around

Solid poly engine and transmission mounts

Chassis setup by the late John Coffey at Beta Motorsports (known for building Zs)

Drivetrain:

Series 2 RB25DET with approx. 40k miles (custom install welded into factory locations)

Nismo single disc clutch kit and pressure plate in RB25DET 5spd transmission

OS Giken 2-way clutch LSD in upgraded R200 long nose differential with new half shafts

740cc Nismo injectors w/ Bosch 044 fuel pump

Super Spark coil packs

Upgraded factory housing turbo

Apex'i PowerFC and Greddy Profec B controller dyno tuned up to 370RWHP, but run at lower boost (325RWHP)

New OEM MAF and Apex'i intake

HKS Blow off valve

Oversize radiator and front mounted intercooler

200ZR oil pan

Functional check engine light

3" exhaust front to back

New half shafts

Interior:

New interior including OEM kick plates, door panels, etc.

Original dash with a fitted cap

Recaro SRD seats with custom leather inserts (driver seat fully adjusts, passenger fixed due to roll bar)

4pt harnesses on both sides

Properly installed Kirk Engineering roll bar

Speedhut custom gauges in factory locations (GPS speedometer which measures 0-60, 1/4mi, etc)

Modern fuse panel

Nardi steering wheel

Rear 6x9" speakers with bluetooth

Roll on sound deadening throughout

USB charging for accessories

Upgraded interior fan blower motor

Exterior:

No rust, any repair replaced with new metal. No bondo anywhere.

Complete bare metal paint job in PPG Ferrari Blu Chiaro paint (80s 328 color)

Custom carbon fiber panels and rear 432 style spoiler

Upgraded H4 headlights

MSA urethane front air damn

Carbon fiber bumpers

New front and rear glass

New rubber seals all around

Advertiser

JagdStealth

Date

06/17/2019

Price

$35,000.00

Category

Cars for Sale

Year

1972

Model

240Z

Vehicle Identification Number (VIN)