Hi Odinspeenbone

Welcome to the forum. As you probably already noticed, plenty of willing members to offer advice where needed.

Looking at your photos, I would rebuild it. You mentioned in your first post, you found a tooth or a piece of one. Most probably from the reverse gear. The reverse gear can look very ragged, and still function well. Can you post a photo of the piece and maybe locate where it came from?

Points to check before going forward with rebuild.

- Look for cracks in the gears. A small chip will be ok, but cracks and signs of shattered teeth are a red flag.

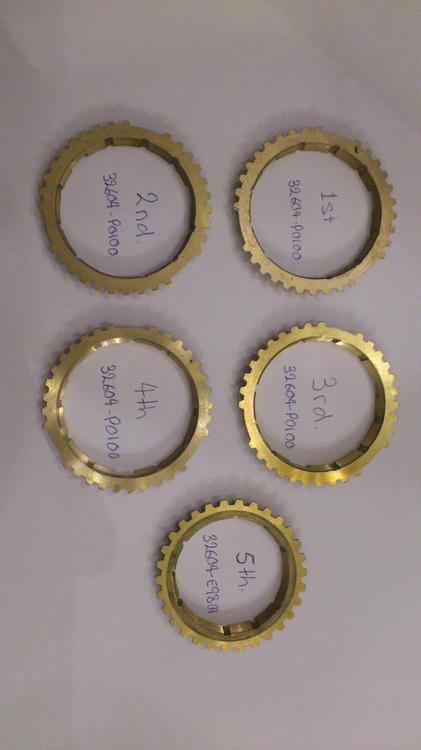

- Syncho rings. Was the gearbox changing gears without grinding befoe the bearing fell apart? If not measure the rings against the specs, see manual for guidance. The external teeth look OK on the photos, but that is not what makes a good synchro ring. The small grooves on the inside are important and the wear is determined by measuring the distance between the synchro cone and the gear.

Note: Be carefull running your fingers around the inside. The small grooves can be razor sharp, especially on new rings.

If the synchros are within spec, you only need a bearing kit and seals.

- Once it's all dismantled, check the shafts are straight and within tolerance. Bent shafts can caused the transmission to jump out of gear. Didn't do it with worn bearing because the worn bearings had enough play to compensate.

- Use a good quality GL-4 transmission oil suitable for brass synchro rings. Redline MT-90 or the GM transmission oil are commonly refered too. The GM part numbers are AC DELCO USA p/n: 88900399. GM USA p/n is: 12377916.

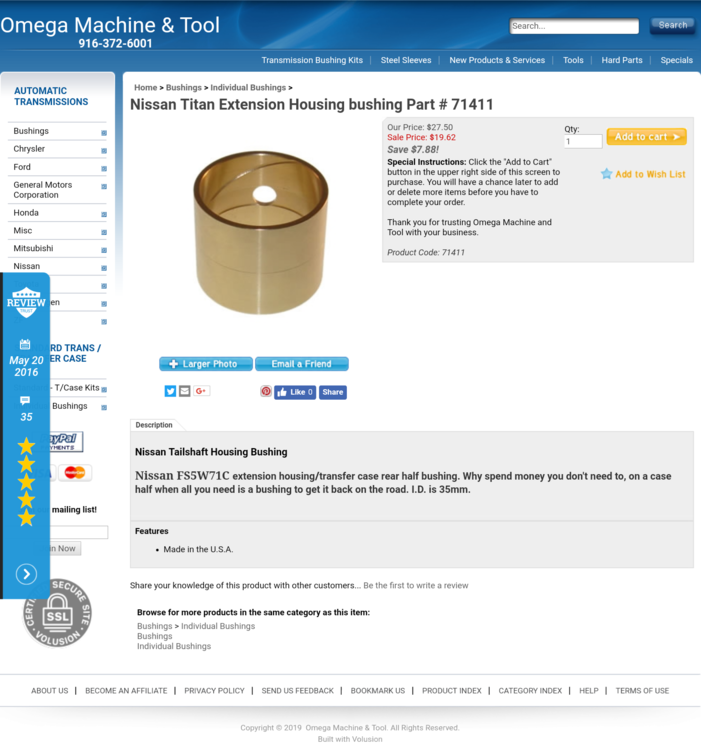

I can post the part numbers for all the seals if you want to order then individually. Best would be to order a bearing kit and the rest of the seals, o-rings separately.

A kit like this would be what you would want for the bearings. They also sell bearing kits with synchros, but I have had poor performance from the aftermarket rings and endd up sourcing the rings from Nissan.

DTS-BK133

$129.89

http://www.drivetrain.com/parts_catalog/manual_transmission_overhaul_kits/nissan_f5w71_overhaul_kit.html

Subscriber

Subscriber 4Points1,341Posts

4Points1,341Posts Subscriber

Subscriber 4Points2,392Posts

4Points2,392Posts Subscriber

Subscriber 2Points11,182Posts

2Points11,182Posts