-

ITM Piston Rings

Now that’s a smart Dawg!

-

-

ITM Piston Rings

Hi Site…..When installing new pistons and rings in an expensive rebuild, I want to feel confident that when I squeeze those pistons in the bores, they are perfect. The ITM pistons are awesome. When installing rings, I have found that the Total Seals oil rings mate up so easy that I can sleep at night shoving the pistons into the bores…….just me. I’m sure that ITM oil rings and Hastings will work, but I just never felt like I had them installed correctly….at least not in my mind. An extra $200.00 for top quality rings always seemed worth the investment…..whatcha think? BTW How’s your dog? Regards Guy

-

Z's on BAT and other places collection

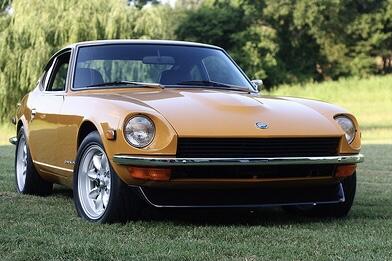

Hi Zed…..No, Chuck’s Frame Shop is a restoration shop…..mostly Porsches. He did two of my cars….both took two years. He, in my opinion is the absolute best…..no corners ever cut. I also use him for other items like spoilers…front and rear and he took the side panel strip off my silver 73 and matched the original paint to perfection. I don’t know the seller, but the owner is a good friend and never lets price get in the way of a great restoration. Here are a couple Chuck did for me.

-

Z's on BAT and other places collection

Wow…..This is a tough crowd. Not everyone restores a Z to exactly mimic what came off the showroom floor. It just doesn’t get much better than this, and he probably won’t make much if anything on the sale ( I’ve used Chuck on all my restos and he ain’t cheap). Also, the little hole in the air cleaner for a couple thousand miles is a no event, but I use a wine bottle ratchet cork to seal mine. Amazing that he came up with a rust free Series I…..that just doesn’t happen very often on a 55 year old Z.

- Charging fun with Zedyone !

-

Diseazd started following Repaint Refresh of HLS-02446 3/70 , Still struggling with car at idle after 8 years , [2025] What Did You Do To/with Your Z Today? and 1 other

-

Still struggling with car at idle after 8 years

Reach under the carbs when the car is running and push up on the choke nozzles. If they are hanging up it causes the exact problem you have. you’ll hear a little snap if they are indeed hanging up. If Ztherapy built the carbs, you can feel confident its not in the carbs. IMO

-

[2025] What Did You Do To/with Your Z Today?

-

S30-04858 revival

Wow……Driving trains. That’s something I never knew you did Madkaw. Don’t think you should have any problem getting that name back……no one else grabbed it. 😬

-

Let's show vintage racing pictures. I'll start.

He did Brian…..Read the bridge sign…..Road Atlanta…..bunch of angry Datsuns etc. Happy New Year….hope to see ya soon. PS….I heard they had snow in Atlanta last week….great hill for sleigh rides!

-

Repaint Refresh of HLS-02446 3/70

My son thinks I need Adderall too…….Good luck with the restorations…..like I said, the most satisfying part of owning an early Z.

-

Repaint Refresh of HLS-02446 3/70

Wow, @dspillmana lot of interesting stuff in your pics. First of all, what a great early Z, Looking forward to your progress. What’s the story on I) The race car and 2) All the other Z’s in the pictures. Didn’t mean to divert your thread (I get carried away sometimes) Also, you’re only one state away if there’s anything I can do to help.

-

Repaint Refresh of HLS-02446 3/70

My body and paint guy (Chuck’s Frame Shop) has been in the frame and paint biz for 50 years. He is a perfectionist with all of the right gadgets. I don’t know what that particular frame alignment device is, but he had a blueprint of the 240Z specs taped to the door when installing the new clip. He said the finished product was perfect to spec…..probably better than original.

-

Repaint Refresh of HLS-02446 3/70

- Repaint Refresh of HLS-02446 3/70

- HLS 30 hub caps

It’s not just the gear box that determines the hubcap, it’s all of the other items in a supposed Series 1 or transition to Series 2 Z IMO. Most Series 1 cars had the ashtrays and cig lighters forward of the gear shift, they had angular half shafts and early trannys. The very early cars had 240Z on the roof quarters and vents in the tailgate. Later so called transition Z’s had no vents in the tailgate and picked those vents up on the roof quarters, but all other early features mentioned above stayed (early tranny, ash tray location, angular half shafts, cig lighter etc.) I assume all early Z’s and transition Series 1 Z’s had D hubcaps, but just my guess……Carl Beck @Carl Beckmay be able to add info or @kats @jfa.series1 @HS30-H I would be very interested to know if the transition Z’s (later 71) were considered Series 1 or Series 2? I assume that they wore D hubcaps if they had the early tranny, console and other early items that they came with D caps…….but are the transition Z’s 1’s or 2’s? Anyone? - Repaint Refresh of HLS-02446 3/70

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.