Topics Last 30 Days

Showing topics, images, events and files posted in for the last 28 days.

- Past hour

-

Bodywork Issues

They corrected that mistake with the 260's on - by putting struts on both sides. Not only does a single strut cause the hatch to twist but when closed there's always pressure on one side and not the other. The gas strut is constantly exerting pressure forward on the left hinge and not on the right hinge. You probably won't like the cure as it involves finding a parts Z - 260 or 280 - and removing the mount from the right side strut that's welded on there and moving it to your car so you can add a right side hatch strut. And I don't remember if the early Z hatches have captive nuts for strut mount on both sides or not. We had a guy in Scottsdale rebuilding a 240Z that wanted to add that second strut before he painted so we cut that bracket off a parts car for him. I've never tried to replace the hatch hinge pins (which might get worn). We learned early on to leave the hinges in place whenever possible as they're such a PITA to properly adjust once you've loosened or removed them.

-

Z Restoration Progam

That's what this whole back-and-forth has been about. He has - for many years - repeated the claim that the original plating on the cars [from the factory] was 'Cad'. I say the period Nissan documents specifically tell us that it was Zinc. Why would they do that if it was in reality Cadmium? You seem to be far more ready to accept Carl's anecdote as proof than you are of an official technical description - published by Nissan Japan themselves, in their native language, as part of the component part numbering and identification for the S30-series Z cars, from 1969 onwards - which tells us differently. I have posted an example - with a literal translation - and yet you discount it due to "interpretation"? Same thing happened with the so-called 'Build Sheet' up-thread. Written clear as day, but inexplicably ignored.

- Today

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

@MH77280Z has done this on a 280 if I remember correctly. May be of some help to you. After seeing what you did to your older garage, I'm a little claustrophobic and it made me cringe, I am so happy for you and your new space. 🙂

-

Wheel and tire sets 240z, 280zx, 3oozx

IRON CROSS WHEELS SOLD.

-

240z Engine, 280zx Engine, 280zxt Engine

280ZX TURBO engine SOLD.

-

My two swiss S30Z Fairlady Restoration build thread

Over the last few days, I was busy in my workshop, getting some small tasks completed on my Z project. Time for a little update. After installing the partial gearbox to test fit the brackets and stuff, I realized that the gear lever is too much in the front of the hole: A quick look into the manual made it clear: I had mounted the lever the wrong way. So, gear box rear-end out, gear lever corrected: And back in, this time, correctly: Then I spent a lot of time at the rear end of the car. I had to clean the holes for the three taillight panels, so that the plastic rivets would lock properly. After that i re-installed the taillights, and ensured the sealing rubbers were set correctly, using my "string-trick": Next i have to finish the slightly worn chrome / metal trim around the taillight panels and get them back on: While working at the rear, i decided to install all those fasteners, stoppers, alignment pieces, guides, etc. Like those rubber spacers: And trunk dampers. I have a NOS set of everything, so the installed ones are only temporary, to not mess up the new ones: And the last bit at the rear end was to align the trunk / hatch. The body shop had installed some spacers to get it straight, but after all the parts got installed, I had to remove them again and massage a few areas lightly to have it all aligned: Next? Seat rails. I had those Bride seat rails from my Histrix lying around for a while and wanted to test-fit them. I'm most probably going to use something different setup in the end, but I wanted to ensure that the distance and position of the seat mounting brackets was right after all the bodywork. I thought the best way was to use the original seat rail mounting studs and spacers. Since I had several highly-damaged OEM seats, I hammered out the fasteners and used the plastic spacers after grinding away the factory spot-welds on the bolts. This worked unexpectedly well, so now I can do some trials with different seats, rails and setups - to figure out what will go into the car in the end. Next: I realized that I didn't have any upper rear number plate light in my part collection. Luckily, Florian from Datsun-Autowerk was kind enough to send me one of his broken ones including some other parts (more on that in a following post), for trials. After puzzling and glueing all the parts together... I could mock it up all together and drill the required holes. Fun-fact: I always thought that slight "dent" in the gray metal piece was a production fault of the reproduction panel, but it's actually there to make space for the number plate lighting bolt. After the holes were done and cleaned, I got the upper plastic part installed. And then the whole thing with the lens. Note all bolts and the light itself are temporary units for the mock-up only, final parts will be correct and fresh. Looks good if you ask me! Special thanks to the person who gave me the hint with the holes (I wasn't able to find the mail anymore, but you know who you are!) And then? Spoiler-Alert. Again. After i realized that the currently installed spoiler is beyond repair, I remembered that I had another one lying around. But it was bent in all directions and super wobbly: But all the brackets were still in good shape, so I gave them a little wire wheel brush and corrosion protection: I placed them on our terrace, which tends to get quite hot now in summer And let it take the heat every day. My thought was that the Polyurethane gets weak and goes either back in its natural shape by itself, or can be massaged. At the end, some areas turned out to be pretty stiff, even with heat and required some proper bending over my special bending bench :-) It didn't really work out. It's way better than in the beginning, but still super wobbly. I thought if i'd install it on the car, it might straighten itself a bit. Let's see. I have my doubts. The good thing is, there seems to be another spoiler on the horizon :-) I've seen worse ones, but yeah. Not good enough for me: I also went through my plated fasteners and sorted them a bit. I got various boxes over the years from various collectors and Z-specialists, so it was about time to ensure I find what I'm looking for :-) The to-do list gets smaller by the week. And there's not much left from my side, but some tricky bits. I guess I've earned my favorite Japanese "Hitachino Nest" beer for today.

-

Round top SU carb piston binding

Correct……Always do one carb at a time….piston and dome are precision matched. One more thing, make sure the needles haven’t been bent.

-

New Nissan Canada commercial

Nice ad. If they did it thoughtfully, there might also be promotional value in highlighting two other successful Datsun models from the early 1970's: the 510 sedan (contrast with Rogue), and the 520 pickup (contrast with Titan). Not too many buyers in 2025 realize that the pecking order for Japanese imports back then was Datsun-Honda-Toyota, rather than today's Toyota-Honda-Mazda/Subaru. The decision to re-brand from 'Datsun' to 'Nissan' (1977?) was such an unnecessary a disaster. The bland-mobile 1980's models didn't help either.

-

240z Door Hinge Rebuild

If they fall down can you still get them back up into position? I saw a guy on youtube that unbolted the hinge on the door side first and after the got the car side with a wrench and swivel sockets. I might try to go that route as the car doesn’t fit in the garage (and still work on it, only 2m wide for the first 4 meters). I do have a lager carport where I park the car under to work on it so the car is still dry. That does mean I’ll have to cover the car if I take the doors off but I had to do that anyway.

-

The OG 240Z - Reanimation Project

- Yesterday

-

Chassis Dimensions and the BF-3 PDF

I like to use a wooden shim. Find one that is the right thickness and mark it with a sharpy. Works really well...

-

Let's show vintage racing pictures. I'll start.

- Last week

-

Replace or Not to, that is the question

Hi cgsheen1! Thanks for the recommendations. I am running the latest version of Microsquirt, 440cc Bosch injectors, Spartan 3 v2, crank 36-1 wheel with HALL sensor, LM7 truck coils with batch firing, AZC oil pan. I will try making Microsquirt work with the turbo (no sequential ignition). I have only one output left (relay) which I can use for an electric fan, for ex. I was aiming for 8-10 lbs of boost to play it safe and keeping my stock rear diff/half-shafts alive. I looked up some parts from rockauto and here is a list if it works? EXEDY 06030 clutch kit, 1975 2+2 Flywheel: AMS AUTOMOTIVE / RHINOPAC 167304, for 2+2 model Throwout bearing, WJB / INMOTION PARTS WRDNE01576C (any manufacturer preference?) Hopefully, if the car parts are for 2+2 model, I am not going to run into any issues with the fitment/clutch fork throw. I just installed a brand new master and slave clutch cylinders (for my 280z 1976 model). Will this create a problem? (I checked the part numbers, they are the same for 76 and 75, I think I should be good here). I started a thread here on hybridz dealing with my project: https://forums.hybridz.org/topic/136053-76-280z-microsquirt-project/ Thanks! Den

-

Existing FS5W71B Bearing/Seal Size Inventory?

I have no idea if I did or not, but feel free to copy it over there, or maybe @Mike can duplicate the post there.

-

Autocross Chest Strap

Actually, because of safety, some organizing bodies forbid chest straps without something to hold the shoulder belts from slipping out.

-

Sealing an oil pan

I appreciate the explanation and truly feel your pain doing this in the vehicle.

-

14 inch aluminium for stock 240z

Bit late to the party but I believe my 280z came with the same or allmost the same wheels. Don’t know if they are modified as I haven’t taken the wheels off yet but I must say they look pretty good under my silver Z. Attached is one of the pictures from the auction I bought the car from. The seller also included the original set of wheels but I prefer these. Tire size is 225/60R14 in the rear and 195/70R14 in the front.

- It only works if I spray gas into the air intake.

-

73 Dash Replacement Project

Well done Ken. Perseverance par excellence! Dashboards are not fund to work on.

-

rear clunking noise '76 280z

Understood Darom! If you decide you don’t need them and want to get rid of them, just shoot me a message. Thanks!

-

280Z in the Netherlands

Hi, I don't think he will respond, but you can get your parts from: Z-Services.eu | Shop for Datsun 240Z, 260Z & 280Z I also have a lot of parts for Z's not specific for the 280z as this was never a euro car.. Oh and yes as my name says i'm from the Netherlands too.

-

Z Cars On TV And In Movies

-

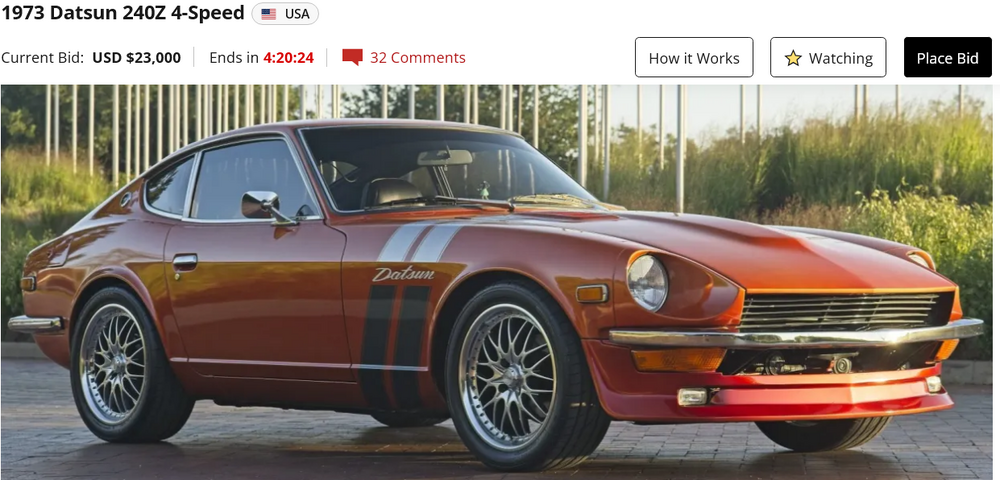

Z's on BAT and other places collection

Back to normal programming. This 240Z auction is ending today but it's already up to $23,000. Kind of surprising considering its unusual appearance. It does look clean though. https://bringatrailer.com/listing/1973-datsun-240z-293/

- Rare 240z Carpet clips. Set of 4

-

Mirror.1971 240Z.

Rear view mirror, with attach brackets and sun visor support pads, including screws. Missing knob to adjust mirror.