Topics Last 30 Days

Showing topics, images, events and files posted in for the last 28 days.

- Past hour

-

Z Restoration Progam

No absolute answer... but interesting non the less. ASK gork: "What can you tell me about Nissan Motor Company using Cadmium plating on automotive fasteners in the 60’s and 70’s?” response below. Information specific to Nissan Motor Company’s use of cadmium plating on automotive fasteners during the 1960s and 1970s is sparse, as historical records and available sources do not provide detailed documentation on Nissan’s fastener coating practices during this period. However, based on general industry trends and the limited information available, here’s an informed overview:Cadmium Plating in the Automotive Industry (1960s-1970s): Cadmium plating was a standard practice across the automotive industry during the 1960s and 1970s due to its excellent corrosion resistance, lubricity, and predictable torque-tension characteristics. It was particularly valued for protecting steel fasteners (bolts, screws, nuts, etc.) in harsh environments, such as exposure to road salt or marine conditions, and for its compatibility with aluminum components, which was critical in automotive applications to prevent galvanic corrosion. The plating’s gold or yellow iridescent finish was common on fasteners in vehicles from this era, including those produced by Japanese manufacturers like Nissan.Nissan’s Context in the 1960s and 1970s: Nissan, operating under the Datsun brand for many markets during this period, was expanding globally, particularly in the U.S. with models like the Datsun 510, B210, and 240Z. These vehicles were designed for affordability, reliability, and fuel efficiency, especially during the 1970s oil crisis. While there’s no direct evidence in the provided sources confirming Nissan’s use of cadmium plating, it’s highly likely that Nissan followed industry standards and used cadmium-plated fasteners, as this was the dominant coating for automotive fasteners at the time. Cadmium’s properties, such as its ability to resist corrosion in marine and alkaline environments and its low-friction characteristics, made it ideal for critical components like bolts and brackets in Nissan’s vehicles. Environmental and Regulatory Shifts: By the late 1970s, concerns about cadmium’s toxicity and environmental impact began to emerge. Cadmium is a heavy metal and carcinogen, and its use in manufacturing posed health risks to workers and environmental challenges due to waste disposal. While European regulations like the 2000 End of Life Vehicle Directive (ELV) and the 2006 Restriction of Hazardous Substances (RoHS) directive later restricted cadmium use, these concerns were already prompting automakers, including Nissan, to explore alternatives like zinc plating or zinc alloys in the 1970s. Nissan’s commitment to reducing environmental-impact substances, formalized in 2007, suggests that by the late 1970s, the company was likely transitioning to less toxic coatings like zinc-nickel or zinc phosphate, especially as it expanded manufacturing in regions with stricter regulations. Nissan’s Manufacturing Practices: Nissan’s manufacturing facilities, such as its Cuernavaca plant in Mexico (established in 1966) and later the Smyrna plant in the U.S. (1980), focused on producing vehicles like the Datsun 510 and B210. While specific fastener plating details are unavailable, the industry’s reliance on cadmium plating during this era implies its use in Nissan’s assembly processes, particularly for components exposed to corrosive conditions, such as underbody fasteners or engine bay hardware. The lack of specific documentation may reflect the standardized nature of fastener coatings, which were often sourced from suppliers adhering to industry norms rather than being a proprietary Nissan process. Comparison to Ford: Like Ford, Nissan likely used cadmium plating for its corrosion resistance and mechanical properties but faced similar pressures to adopt alternatives as environmental regulations tightened. Ford’s struggles with rust prevention and slower adoption of advanced coatings like E-Coat suggest that Nissan, with its focus on economical vehicles, may have prioritized cost-effective coatings like cadmium initially before transitioning to zinc-based alternatives. Conclusion: While direct evidence of Nissan Motor Company’s use of cadmium plating on fasteners in the 1960s and 1970s is not explicitly documented in available sources, it is reasonable to infer that Nissan, like other automakers, used cadmium plating for its fasteners due to its widespread adoption in the industry for corrosion resistance and lubricity. By the late 1970s, Nissan likely began shifting to alternatives like zinc or zinc-nickel plating as environmental concerns grew. For more precise details, contacting Nissan’s heritage division or automotive restoration communities specializing in Datsun vehicles from this era might provide additional insights. - - - - - - End Quote - - - - - - - - -

- Today

-

Z's on BAT and other places collection

Looks like post 79 ZX wheels

-

Options for series 1 dashboard area above hazard switch?

Every single one...

-

cooling fan blade condition

Could well be -> intercooler, -> condenser, -> Koyo radiator (stacked up before the) -> fan. (unfortunately don't have a shroud - wish I did) Plus Phoenix softens up a lot of plastic at times (then dries it out, bakes, and cracks it). And I believe the blade length played a part in my particular case.

-

Interesting electrical issue- Series one car......

-

Let's show vintage racing pictures. I'll start.

-

The OG 240Z - Reanimation Project

Hahaha!! I'm hoping it won't come to that! ☺️

- Yesterday

-

240Z E31 Cylinder Head Complete

-

1977 280Z Both Doors and Rear Hatch

Rust free doors and hatch. Coupe. Black panels. All complete. No keys. $1200.00 Local pickup. These pieces are heavy.

-

1971 HLS30-14938 "Lily" build

The hazard light switch is in that circuit, it could be confusing the issue.

- Last week

-

weatherstrip

Thanks for the tip. That's the one I'll go with. Richard McDonel

-

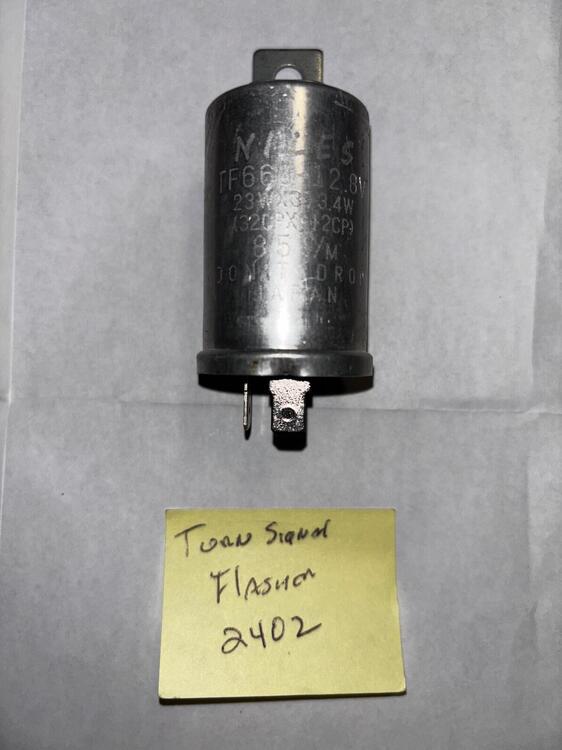

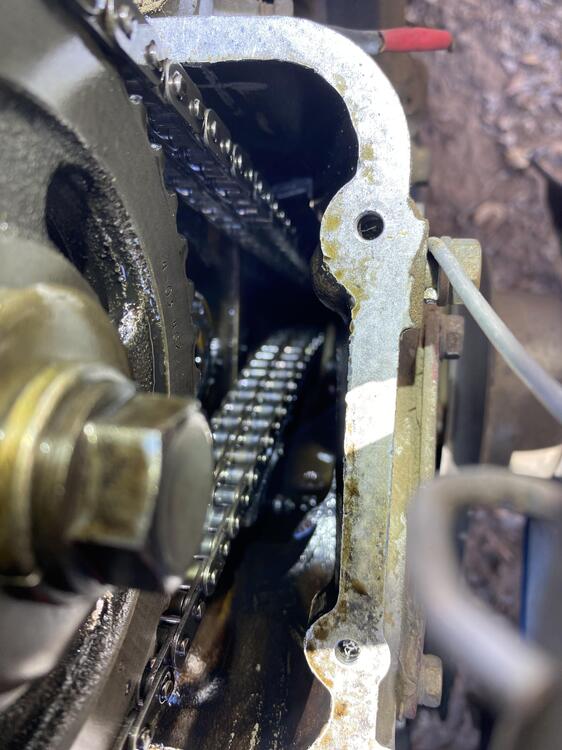

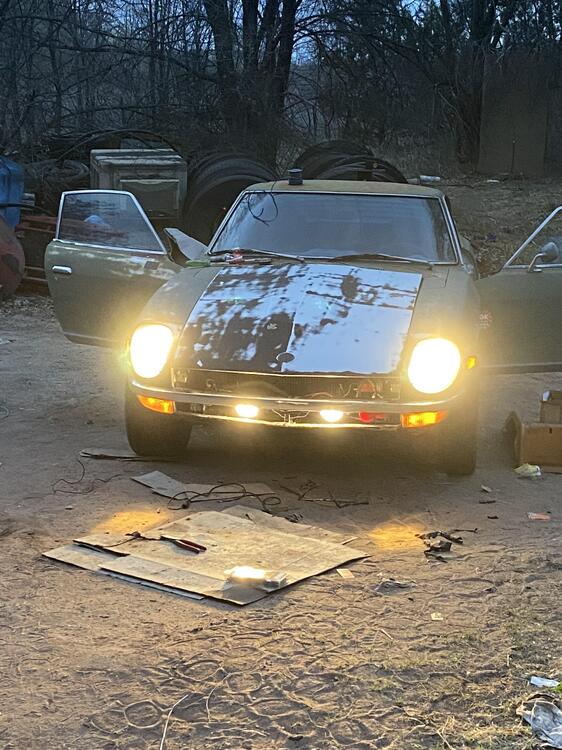

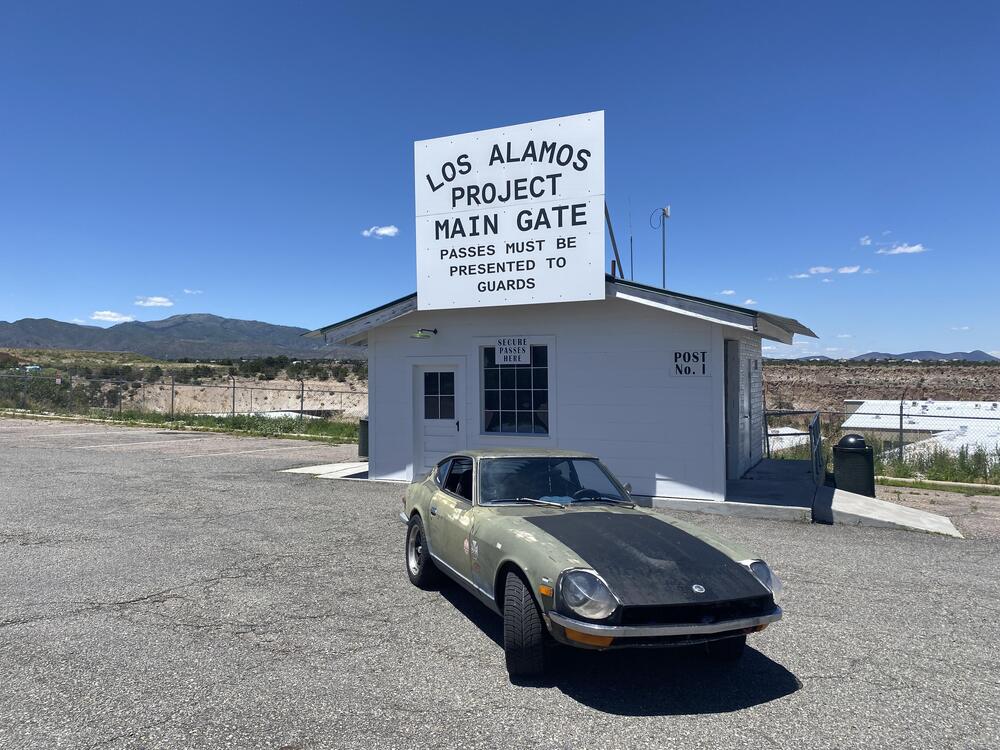

After 8 years of setting I got my 240Z back on the road

So just a little progress of working on my 1972 240Z that I’ve resurrected twice now since I’ve owned it from 2005 or so ..it’s been a long project and not perfect but it was my daily driver . This is where it sat for 8 years untouched next to my 1988 Toyota pickup in December 2024 All loaded up for the 1500 mile return trip in my 1986 f350 diesel I pulled from a field for 500 bucks a year earlier Once I got it home I got it running pretty easy but noticed an immediate problem in the form a rattling noise from the timing cover to discover a broken tensioner and missing bolts . After that issue was fixed I decided it was time to install my big brake kit I got from a junk yard 260z about 15 years ago .. don’t know who made the brackets but the calipers and rotors are from a 90’s corvette .. 12 inch rotors too ..don’t worry about the wheel studs they have been replaced since It also needed the carbs tuned As you can see they were way off plus I discoved the carbs were loose too ..explained why the erratic idle lol I just had to get a star road shift knob Radio was full or rodent crap and figured why not add a wide band afr gauge from auto meter in its place along with my driving light switch ..I still haven’t cleaned the marker off Also had to make my own headlight relay upgrade to run flosser h4 90/100watt ralley lights It’s an L28 with N47 head from a 1979 280ZX upgrades include 45dcoe triple Webbers . Msa 3 into 2 headers msa stage 3 schneider cam along with schneider valve springs Holley blue fuel pump . Kameari Racing distributor and fidanza light flywheel with centerforce clutch . Also running a single grove dampener . I will get the engine rebuilt in the future and get it up to 10.1 cr so maybe I’d get more out of the mods I have ..but still runs great and sounds amazing .

-

saturday night music thread

The writer's version. People have their unique talents. Three Dog Night made it work.

-

Battery hold-down bracket firewall bolt size?

As of this date it is NLA from Nissan !

-

Scallop hubcaps. Pretty nice too.

Facebook marketplace $100. https://www.facebook.com/marketplace/item/1265446158557795/?ref=browse_tab&referral_code=marketplace_general&referral_story_type=general&tracking=%7B%22qid%22%3A%22-8463486491996509719%22%2C%22mf_story_key%22%3A%224732611337300919667%22%2C%22top_level_post_id%22%3A%224732611337300919667%22%2C%22commerce_rank_obj%22%3A%22%7B%5C%22target_id%5C%22%3A4732611337300919667%2C%5C%22target_type%5C%22%3A6%2C%5C%22primary_position%5C%22%3A78%2C%5C%22ranking_signature%5C%22%3A8680157257122688039%2C%5C%22commerce_channel%5C%22%3A501%2C%5C%22value%5C%22%3A0.00097449886189893%2C%5C%22upsell_type%5C%22%3A3523%2C%5C%22candidate_retrieval_source_map%5C%22%3A%7B%5C%2225209201332002879%5C%22%3A626%2C%5C%2225037753125825021%5C%22%3A626%7D%2C%5C%22grouping_info%5C%22%3Anull%7D%22%2C%22lightning_feed_qid%22%3A%22-8463536038638864453%22%2C%22lightning_feed_ranking_signature%22%3A%228680157257122688039%22%7D

-

Oil Pan Drain Plug Crush Washer Direction?

Does it not catch onto the threads, one side of the notch isn't turned up a little? I don't understand any other reason for it.

-

ZCG PARTS: Z Car Garage KW Suspension!

http://www.zcarblog.com/wp-content/uploads/2025/08/477795897_1011115091063663_8033328159812275787_n.jpg Our Z Car Garage KW V3 Suspension is available in limited quantities. These coil-overs offer game-changing performance suitable for street, track and daily-driving for your S30 Datsun Z car. http://www.zcarblog.com/wp-content/uploads/2025/08/IMG_6502.jpg http://www.zcarblog.com/wp-content/uploads/2025/08/481184467_1024485623059943_4520335096885803442_n.jpghttp://www.zcarblog.com/wp-content/uploads/2025/08/480235492_1011115124396993_2250652587135409969_n.jpg http://www.zcarblog.com/wp-content/uploads/2025/08/IMG_8079.jpg View the suspension installed on Sung Kang’s RB26DETT-powered Datsun 240Z, Larry Chen’s SR20DET-Powered Datsun 240Z, James’ turbocharged L-series powered Datsun 240Z, Mrs. Butters, our Series 1 shop 240z and more client cars in the photos below. For more information on ordering and pricing please contact RobATzcargarage.com. Christopher’s 1977 Datsun 280Z http://www.zcarblog.com/wp-content/uploads/2025/03/IMG_0100.jpghttp://www.zcarblog.com/wp-content/uploads/2025/04/79132B3E-9580-4354-8193-A495343542AA.jpg http://www.zcarblog.com/wp-content/uploads/2024/04/Snapinsta.app_435453951_1100584987877003_6251338209217300970_n_1080.jpg Rashid’s Datsun 240Z http://www.zcarblog.com/wp-content/uploads/2023/12/IMG_3644-1024x768.jpeghttp://www.zcarblog.com/wp-content/uploads/2023/12/IMG_3668-1024x768.jpeg http://www.zcarblog.com/wp-content/uploads/2023/12/IMG_3660-768x1024.jpeg Larry Chen’s SR20DET-Powered Datsun 240Z http://www.zcarblog.com/wp-content/uploads/2025/08/482238822_1031449779030194_8541949018636167241_n.jpg David’s Datsun 240Z http://www.zcarblog.com/wp-content/uploads/2023/12/IMG_3914-768x1024.jpeg http://www.zcarblog.com/wp-content/uploads/2023/12/IMG_3658-1024x768.jpeg Sung Kang’s RB26DETT-powered Datsun 240Z http://www.zcarblog.com/wp-content/uploads/2023/04/230321attctn01_AD4I1590-1024x683-1.jpeghttp://www.zcarblog.com/wp-content/uploads/2021/10/IMG_6847-768x1024.jpeg http://www.zcarblog.com/wp-content/uploads/2025/08/489963857_10161147860356524_8556000592169917657_n-scaled.jpg Rick’s BRE-240Z inspired track car http://www.zcarblog.com/wp-content/uploads/2022/12/320600770_1009589563765747_4277675222190800456_n-1024x892.jpeghttp://www.zcarblog.com/wp-content/uploads/2025/08/IMG_7934.jpg http://www.zcarblog.com/wp-content/uploads/2025/08/IMG_7942.jpg Yoni’s Datsun 240Z http://www.zcarblog.com/wp-content/uploads/2025/08/482246435_1031972718977900_6077886151500554509_n.jpg James’ turbocharged L-series powered Datsun 240Z http://www.zcarblog.com/wp-content/uploads/2022/03/IMG_6794-1024x768.jpeg Mrs. Butters, our Series 1 shop 240z http://www.zcarblog.com/wp-content/uploads/2024/12/468610894_1296792398175930_6743499117304711_n.jpg http://www.zcarblog.com/wp-content/uploads/2025/08/508182070_10161384649461524_7603414350984985404_n.jpg View the full article

- Tire size. Confirm once and for all...

-

Looking for a nice 240Z Front Hood to fit 1972 Z

Hi, I'm looking for a nice hood for my '72 Z. Anybody got a nice one for sale? I'm located in Seattle, WA. Thanks!! JH

-

240Z Hood Front Lip Corners - Need stock reference photos for my repair.

Ahh. This is interesting & helpful. My tip is closer to the red (stock) above. And my corner (1 of them ) is closer to the red one too, although I'm uncovering atleast 1/8 inch of bondo (see pic) Question #2: Does anyone have any info/experience related to the remanufactured steel hoods available on ebay, etc? I see that they're going for anywhere from $800-ish to $1200-ish. I'm considering that as option. Any thoughts, advice, etc? Thnx! JH

- Earlier

-

New Nissan Canada commercial

Thanks for sharing! I don't watch much TV, so when Diane told me there was a Nissan ad with what looked like a yellow version of my 240, I had to check. Cool ad, although there will be those among us who find the rubber-burning, wheel-spinning parts to be "deeply offensive," to which I say, "suck it up baby sisters."

-

Bodywork Issues

That makes sense, but the problem is really just cosmetic (once I've confirmed that the exhaust problem has been corrected), so I don't think I want to go as far as adding a second strut to correct it. I don't think all cars with the single strut have raised driver side hatches, though, so I'm thinking that there are other ways to address this. If the hinges are worn, that might be a place to start, or maybe the two hinges just need to be adjusted relative to each other to lower the driver's side? At this point I haven't glued the seals back in or attempted to adjust the hinges or latch, so I think I'll move ahead with those steps and see how close I can get things to flush. The upper portion of the new inner seal is almost vertical when installed. When the hatch is closed the vertical portion slides outward against the underside of the hatch to create the seal, so I expect it to compress a little over time as well. As an aside, I was happy to see that, with a couple of careful initial closings where I manipulated the seal at the hinges, the seal is sliding over them properly. Both my original seal and the replacement were mangled by the hinges. I've been procrastinating on the next steps because I know I'm not going to enjoy removing the adhesive from the car before gluing the new seal in, but I'll report back when I've made progress.

-

Round top SU carb piston binding

If you do one at the time you have a (mirrored) example there to see how it sits/comes together again.. and... ALWAYS make pictures BEFORE taking apart.. it's so easy to miss that sequence of the little rings/parts on there! RULE NUMBER ONE: MAKE PICTURES OF EVERYTHING YOUR GONNA RESTORE!

-

The Development Story & Specification Of The European Spec Datsun 240Z

The first versions were (as far as i know) never sold officially, but only delivered for testing as prototypes. Some ended up in private ownership. but i guess those were very few. The upgraded suspension, front and rear spoilers, 5-speed transmission and the different front turn signals, etc were standard equipment on all european cars. Even though the parts catalogue lists things as optional, as far as i know, most (all?) european Datsun importers didn't sell any dealership options and most cars were sold as standard european final spec cars. Aside from Portugal, of course, which had their own specifications.

-

240z Door Hinge Rebuild

I think it can be unbolted with the fenders on. just enough room with a swivel, a bent wrench, some friends and a 6 pack. lol The backing plates can be retrieved if they fall, use a stick magnet, you might have to remove the ECU, Holding them in place while starting the bolts is another circus act. get some friends back over and a 12 pack. haha!!