Let's go over the theory of operation in an effort to help explain what is going on.

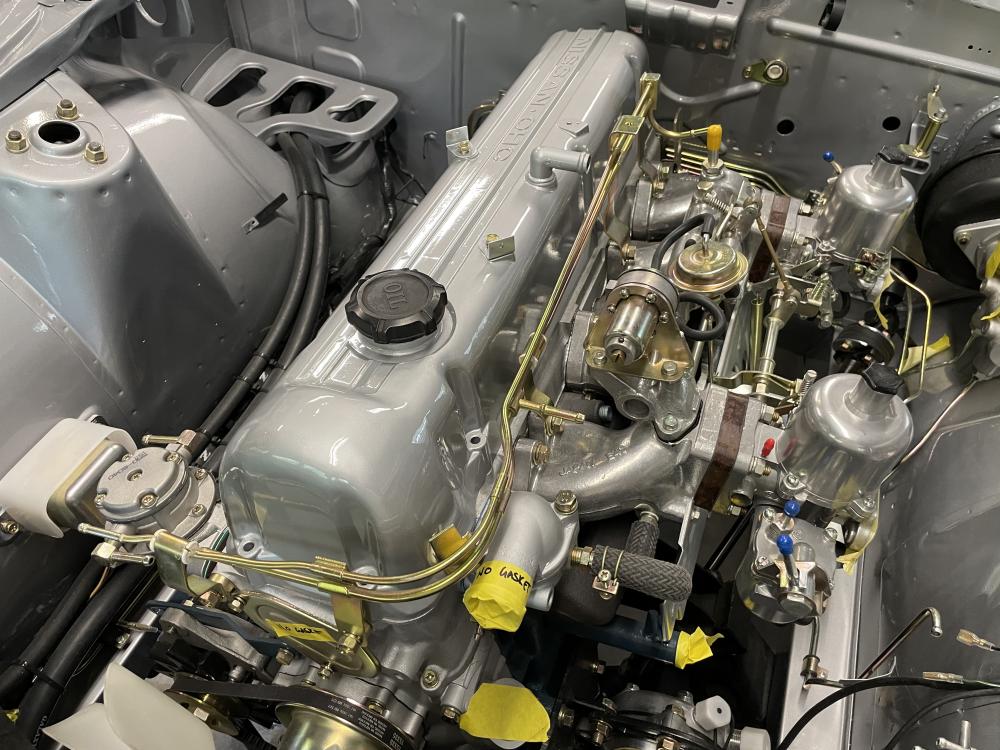

When Nissan changed carburetors between the 72 and 73 model years, more complaints were received about vapor lock. Nissan implemented a couple of "fixes".

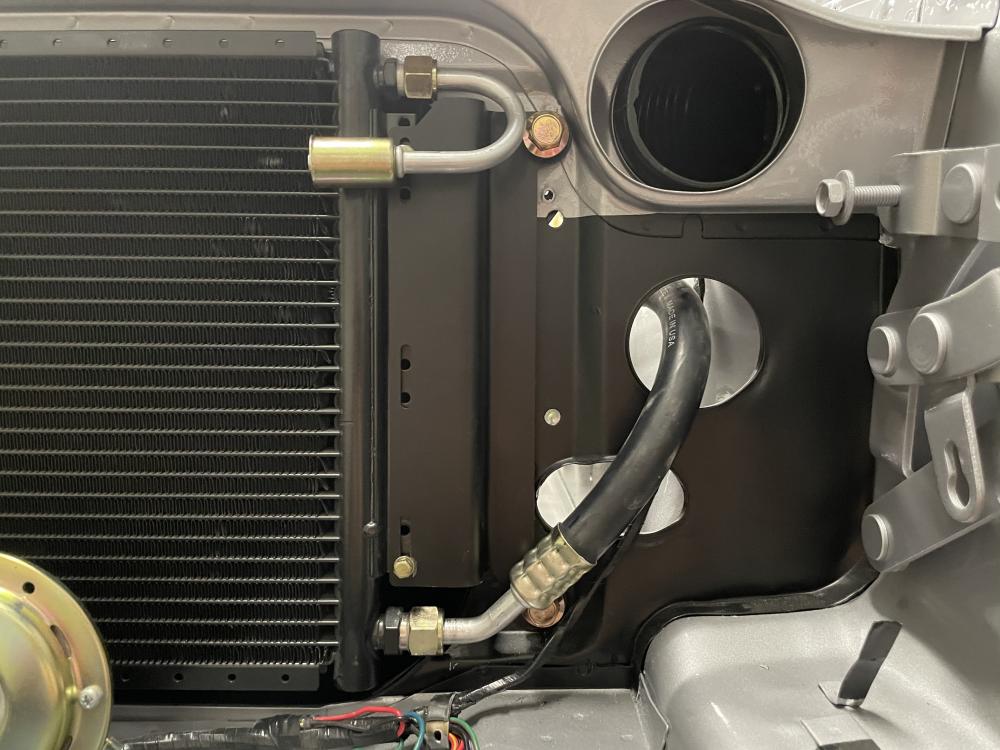

Insulate the heck out of the fuel rail including the individual hoses from the rails to the carburetors. (Mmm, asbestos!)

Add a helper electric fuel pump to the mechanical fuel pump to push cool fuel through the lines blocked by the higher pressure vapor.

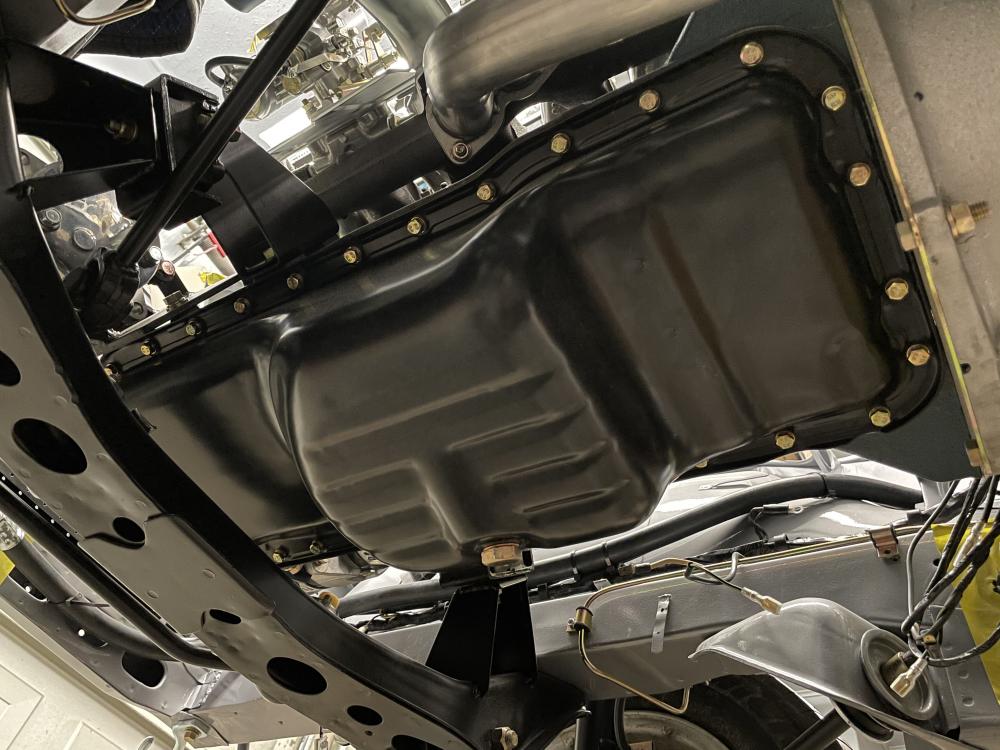

When the car is starting, it uses the fuel in the float bowls, and you don't need fuel pouring into the float bowls. As a matter of fact, it is easier to push the vapor if the carburetors have used some fuel during starting, lowering the float to open the float valve.

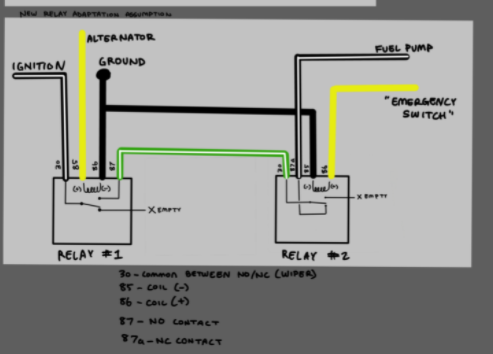

So now let's look at the fuel pump relay circuit and talk about what happens. The drawing is from page EF-7 in the 74 FSM. I enhanced the descriptions so you can see it better.

Let's first talk about Fuel Pump Relay #2 (FPR2). The coil of FPR2 is energized when the key is in the START position. When the coil is energized, the fuel pump circuit opens, preventing the operation of the fuel pump. When you release the key to allow it to go from START to ON, the coil for FPR2 de-energizes, the contact closes, and that part of the circuit is completed again.

Now let's go to Fuel Pump Relay #1 (FPR1). The coil of FPR1 is energized by the neutral of the alternator. So what is the voltage of the neutral? Let's go down the rabbit hole a little bit.

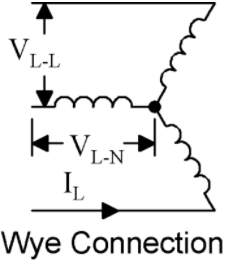

If you measured the voltage coming off the windings of the alternator you would see AC voltage, specifically 3 phase AC voltage. In power generation terms, we call the configuration of the alternator WYE because each of the three phases connects to a common "neutral" point. As you can see, when I rotated the first image, it looks like the letter "Y". If you ground the neutral, the voltage from neutral to ground becomes zero, but the neutral isn't grounded in our cars. Now, the output from the alternator goes through a rectifying bridge. This uses diodes to stop the current from flowing in the reverse direction, and with the 3 phase waveforms, the output is close enough to a DC square wave that it is usable to the DC electrical system.

The output of the alternator is about 14.5 volts. Knowing that, we can calculate the voltage to ground. (You may have seen @Captain Obviousand I discussing that on another thread. He keeps me from going down the wrong rabbit holes.) To get the neutral to ground voltage, we can divide the alternator voltage by the square root of 3 (1.732), giving us about 8.3V. That is enough to energize the coil of FPR1.

With the key in ON and the alternator turning, FPR1 completes the full circuit to the fuel pump. (With the key in ON, FPR2 is not energized, so the contact is closed, allowing current to flow through it.)

If the engine dies, the alternator stops turning. The voltage from neutral to ground goes to zero, causing FPR1 to open the fuel pump circuit even if the key is on. There is no separate emergency switch.

So here is the maybe useful trivia. You may notice posts saying that instructions for going to an internally regulated alternator won't work on a 260Z. This is because of how FPR1 is energized. If you change the wiring for an internally regulated alternator, you lose the neutral output from the alternator. This means you would need to find another source for the FPR1 coil and probably incorporate an inertia switch into the circuit for safety.

Subscriber

Subscriber 18Points348Posts

18Points348Posts