Everything posted by SteveJ

-

280z DASHBOARD REMOVAL / UPGRADE

Another way is to go through the tachometer opening if your hands are small enough.

-

Euro / JDM taillight wiring

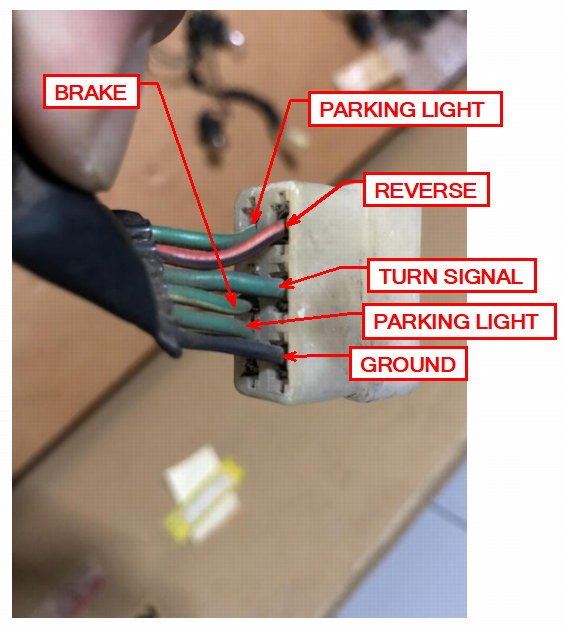

I don't believe that can happen for the North American market 240Z. The brake light and turn signals share the same bulb for the rears. Look at the turn signal switch. That's where it happens. You can make an adapter plug, but you have to add a wire for the brake lights.

-

Z's on BAT and other places collection

GVWR is gross vehicle weight rating. That should be the maximum weight with passengers and luggage/cargo.

-

Euro / JDM taillight wiring

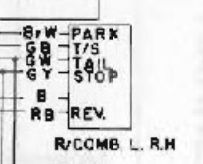

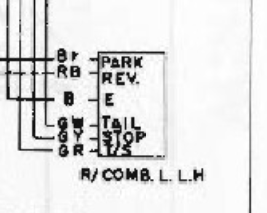

The 72 FSM has the colors. In @kats connector it does not show a Br or BrW wire. It shows two GW. This may be the correct orientation:

-

vin number

The 17 digit VIN didn't start on the Z line until 1981. As @Patcon mentioned, the VIN does not contain much in the way of a build code. For the 79 & 80, I'm not sure where the paint code was located. It might be a foil sticker on the radiator support, like the S30. It looks like later years of the ZX had the information you want on the plate in the engine bay. This site may be able to provide you with more information: https://www.xenonzcar.com/s130.html It has color codes for the interior and exterior: https://xenonzcar.com/s130/colorchart.html

- Is anyone there?

-

Is anyone there?

- Suspension

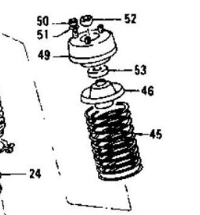

Actually the picture and part number is from the front suspension parts microfiche that is on carpartsmanual.com. If it says Pathfinder, it's because they used the same part on it.- Suspension

Part 46 NLA 46 ASSY-BUMPER BOUND 54050-E4101 L24-2 SEATER,2 SE ATER 2 54051-N3400 7409 2 54051-N3400 2+2 SEATER 7310 2- Suspension

Part 49 49 ASSY-INSULATOR STRUT 54320-E4100 And still available from Nissan. https://www.nissanpartsdeal.com/parts/nissan-insulator-strut~54320-e4100.html?vin=&make=Nissan&model=Frontier&year=2024&submodel=&extra1=&extra2=&filter=(r=1686)- Restoration Shop

That was me who made that suggestion.- 1973 240z Custom Wiring From Scratch

I used the two prong electronic flashers for a while after converting to LEDs. I found that some of them had spotty performance. After that I switched to 3 prong flashers and grounded the third prong. That has provided reliable performance for years.- 1973 240z Custom Wiring From Scratch

I thought it was a shining analogy.- Quiz Time! Water Pumps

You can get a new Aisin WPN-013 water pump. I have no idea whether or not GMB was an OEM supplier, but Aisin is a Japanese based company that is a parts supplier for that country's automotive industry.- 1970 Wiring Diagram

I'm not sure of the location on the 70/71. I think for 72, the body ground moved to frame rail. I'm pretty sure it's on the frame rail for the 73.- Series I is more hesitant to Start

- Series I is more hesitant to Start

- Series I is more hesitant to Start

- New Fuse Box To Replacce Fusible link Holders

Find a weather resistant maxi fuse (or ANL fuse) holder if you are planning to mount the fuse holder where the current fusible link holders reside. I also suggest using ferrules on the wire ends to improve clamping force on the wires. You will need to find a ferrule crimper that can handle the wire sizes (relatively easy to find on Amazon). Here is an example of a marine ANL fuse holder: https://www.crutchfield.com/p_867FUSEDIS/Wet-Sounds-WWX-FUSE.html- Series I is more hesitant to Start

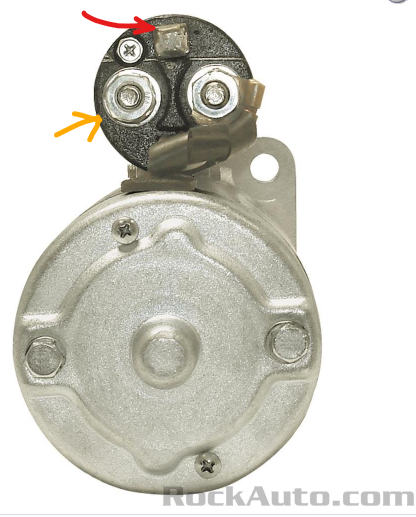

The click you hear is normal. That is the accessory relay. Move on from that. You need to verify voltage to ground (or negative) at the starter solenoid when the key is in START. That is the black/yellow wire. Suggested actions: Pull the black/yellow wire off the starter solenoid. Put the positive voltmeter lead on the black/yellow wire and the negative lead on the battery negative. Have your assistant turn the key to the START position. Measure the voltage (and report it here). If you have around battery voltage at the black/yellow wire, then here is the next test. Keep the black/yellow wire removed. Ensure the car is in neutral. Get a screwdriver. Touch the screwdriver to the positive cable on the starter and the spade terminal where the black/yellow wire was. You don't have to hold it there for long. If it doesn't engage the solenoid immediately, try a couple of more times. Red arrow - Spade for black/yellow wire Orange arrow - Positive cable from the battery. If the solenoid immediately engages, then your starter solenoid is probably in good shape. Report your results.- 240Z original tires

Also: https://www.vredestein.com/classic-tires/products/990-SPRINT-CLASSIC/ Tire Rack link for the above tires: https://www.tirerack.com/tires/tires.jsp?tireMake=Vredestein&tireModel=Sprint+Classic&sidewall=Blackwall&partnum=7HR4SC&tab=Sizes- 240Z original tires

Look here: https://cokertire.com/amfinder/index/index?finder_id=33511382- SN 00042 Restoration; The Older Twin

https://www.zzxdatsun.com/- PDF versions of 240z Haynes manual & "How To Restore Your Z-Car"?

@Mike, I think osinpowe may be some kind of bot or spammer.- FRENCH 1972 240Z

- Suspension

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.