-

Building Up HLS30-59920

-

Building Up HLS30-59920

Thanks! They have been a huge PITA up to this point. Found out the hard way 3-piece 16” wheels do not clear the calipers without a spacer.

-

Building Up HLS30-59920

Suspension components back from anodizing and powder coating. Plated hardware also received. I’ve got the shell just about to a roller stage. Need to mount tires on the Epsilons and see if the wheel setup is going to fit or not.

-

Building Up HLS30-59920

A bit out of order, but along the way we also finished out the interior. Here we used Lizard Skin ceramic coating as a base, then top coated with Raptor Liner to give a durable finish in yellow.

-

Building Up HLS30-59920

-

Building Up HLS30-59920

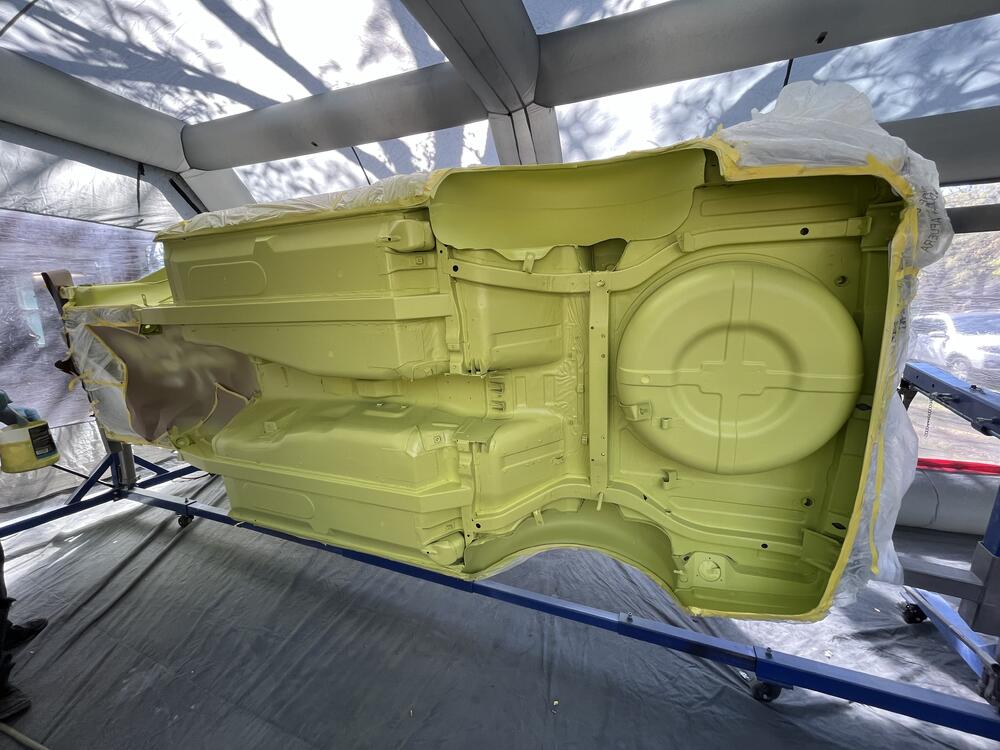

Getting color on the body. Previously on the fuel tank we sprayed the top coat with Raptor Liner, reduced enough so you could use a traditional HVLP gun. This gave a very fine texture, similar to what’s on the dash. Really liked the finish so we replicated the same procedure with the underside of the car in the factory color.

-

Building Up HLS30-59920

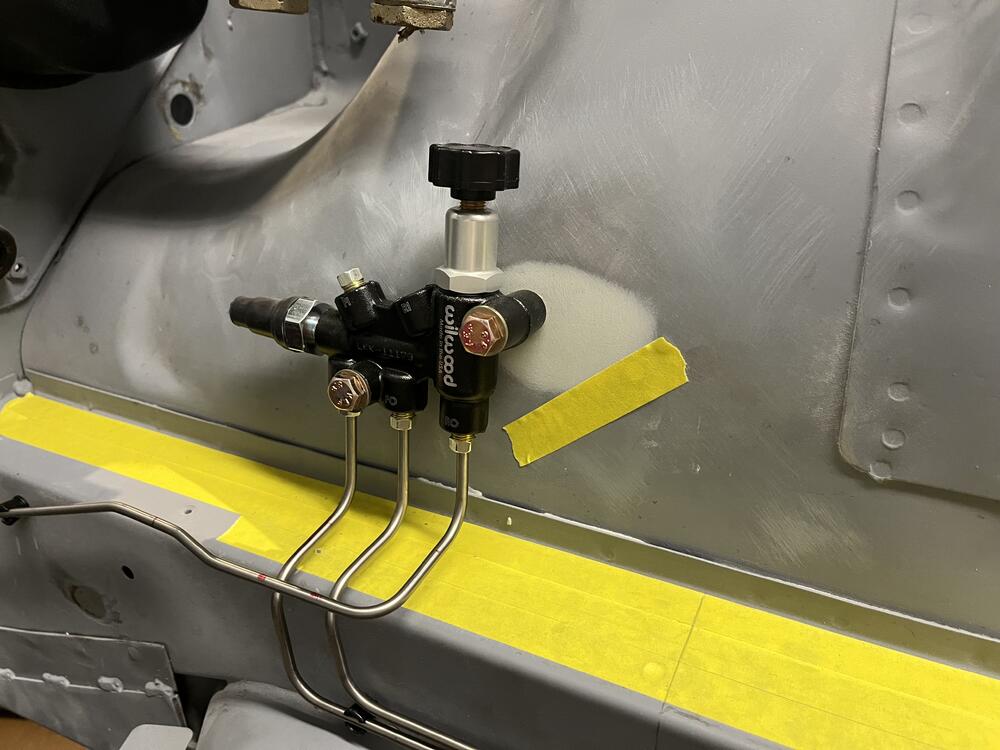

Purely aesthetics. I didn’t want to cross over the fuel lines with it as they’re routed right above the clutch line. I’m getting really good at making simple things harder.

-

Building Up HLS30-59920

-

Building Up HLS30-59920

-

Building Up HLS30-59920

Massive photo dump impound - bunch of progress made over the past few months Full T3 suspension going under the Z. Color choices from T3 aren’t the best, that’s in the works to change BC extreme low coilovers Ztrix dash also arrived. Top notch piece from John. Lots more to come on this

-

Building Up HLS30-59920

Just about done with the AC hardlines. Once I get the dash built up I’ll finish plumbing these up to the Vintage Air unit.

-

Building Up HLS30-59920

Absolutely, I’ve got special pucks I made with a notch down the middle to slide over these jack points for the 2 post

-

Building Up HLS30-59920

Most likely the case, damage that was done by the previous ownership. Passenger floor pan had rot where it overlapped the frame rail, right under the seat brackets. The drivers side probably could have been saved. It had some rot where it met the firewall and a few big dents I was worried would never fully come clean. Gambled replacing the entire panel would be quicker than all the smaller jobs.

-

Building Up HLS30-59920

Front end plumbing is just about complete. Intercooler installed, piping from turbo to intake laid out, and giving a go at making stainless hardlines for the AC system that will package around the 3" intercooler piping.

-

Building Up HLS30-59920

Wasnt bad at all to work with. A good box knife will make quick work of trimming these to shape. Only con to the material is the diamond texture it has on the top. Not 100% accurate, but the thickness/function/ability to paint was good with me.