I see it has been a long time since I posted an update. I am still working on fasteners. I suspect that I am putting too much time into them, but I have no experience with getting hardware replated. So, I feel I can't leave it up to chance. I will probably send some "test" hardware along with it in various stages of prep or lack thereof. It will be interesting to see how the test hardware compares to my fully prepped hardware.

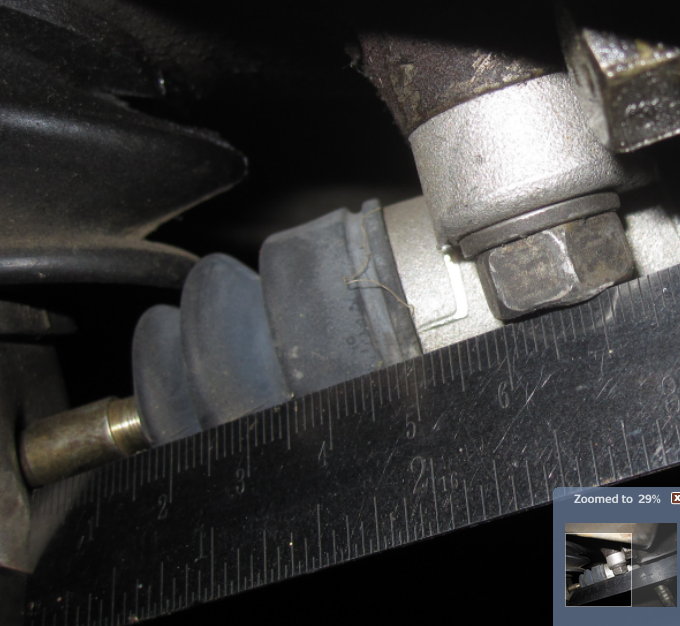

I have a few observations to share, but not much of an update. First, the u bolt that holds the steering rack from twisting on the front crossmember - I happen to have two. There is a white blot of paint from the factory. I noted that under the white blot, the part was silver. So, this part seems to have received zinc plating (clear) from the factory.

The clips that secure a rubber weather strip to the unibody under the top of the fender, here in their as removed condition. Amazing that they don't even have rust on their entire surface:

The battery inspection panels have these metal clips. I find it interesting that they received a black coating originally that is not paint. This is actually consistent with other black plated parts I have found on the car. Black parts are, nearly without exception, springs or springy.

The bushing in the bracket that bolts to the engine compartment firewall, which supports the back of the main throttle rod, is always rotten on any 240z. It is a two piece bushing, with a plastic inner barrel and a rubber outer grommet. The rubber part broke when I pried it out of the bracket. Here it is temporarily put back together:

First pic has half of grommet removed. Middle pic is of the plastic barrel by itself. I will be trying to source a similar bushing from McMaster Carr.

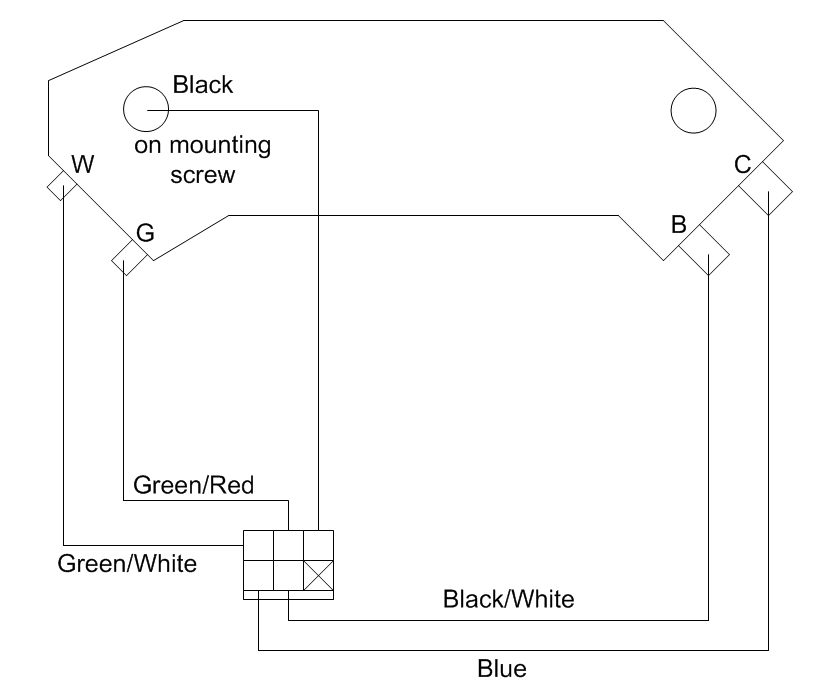

And lastly for today, I find it interesting that the hatch hinges were bolted into the car when it was painted at the factory. The odd part about that is that the rubber enclosure was in place also. My car had shims on the right side hinge only, and you can see by the original paint that they were in place when the car was painted. This, and the fact that the taper head bolts that hold the hatch to the hinges were not originally painted, tells me that the hinges and hatch were bolted to the car for fitment, and then the hatch was removed (the four taper head screws only were removed) for the original paint application at the factory.

Also, hinge assemblies and shims were clear zinc, and backing plates were yellow chromate/cad.

I think I am nearing the end of the great fastener round up and restoration of 2020/2021. I ordered some new ones a couple of days ago to fill in for the small number of originals that went missing at some point. I am digging through my boxes of old Datsun hardware to find suitable replacements also. I am having some success there, finding matching hardware with 4's and 7's and 9's on the heads of bolts - proper style and length. Yeah... I am more than a bit OCD I think.

Subscriber

Subscriber

.thumb.jpg.b670be784e31f4c420a47f82718596ef.jpg)