Everything posted by ETI4K

-

Caswell Plating

I can't get to mine to check, but couldn't we machine (mill/lathe) or 3D print the plastic parts? I know they wouldn't look OEM, but they'd serve their purpose. Furthermore, I'm certain the rivets (as seen in the previous pics of the hatch and door parts) can be made, though staking them could be rough.

-

Caswell Plating

I would suggest that if you are plating for corrosion resistance, remove all removable parts. It's a different problem with assemblies that are riveted or staked. How do you replace the rivets or restake something without tooling? I suppose you could always make them. If you plate the door latch as an assembly, I suspect you'll get little protection for your effort.

-

Cut open and reweld fuel tank?

Alas, that tank is still in two pieces. The job of gluing it back together has been kicked back from the forefront of efforts/work more times than I care to recall. Absolutely, cutting it apart was the best (only way for me) to get the metal right. Fortunately, there's very little interior corrosion, just bad bruises (which I still cannot figure out it happened). The one remaining area to straighten that is inaccessible from inside is immediately below the in-tank filter. I'm thinking of deleting it altogether to get the dents, and I want to slosh around some tank sealant and the prospects for getting fuel the filter look terrible at best. I haven't been on here so much lately, largely bc of the seriously annoying ad experiences 😉. I know I can throw money at it to make it go away (mostly?), but haven't gotten there yet.

-

Ran across this Advertisement on Amazon today

It wouldn't hurt my feelings at all if it were mine.

-

Heater valve

I'm with Hussein. There's a lot of pleasure taken from bringing a worn part back to life. I've repaired more switches, valves, contractors, etc. than I could ever count, and most have continued to operate for many years. Having a 3D printer helps! Nice work bead blasting. Did you do it wet or dry? It looks perfect. I once found a place that would sell you one oring. Amazing! or so I thought, then they add the shipping. Really? $15 to mail one oring? Buy the bag of a 100.🙄 Think of the business you could start repairing heater valves.

-

resurrecting a 1977 280Z

It occurred to me as I was leaving this page after having read this (and agreeing), that this forum has attracted and retained amazingly friendly and helpful soles. I've been on and off here a long time and every time I dig into someone's topic and read the community's offerings I am reminded how much I appreciate them and admire the seemingly endless well of knowledge and encouragement freely given. I enjoy being here and hope I can pay it forward.

-

resurrecting a 1977 280Z

It's always nice to hear one running up through some gears. Sounds great.

-

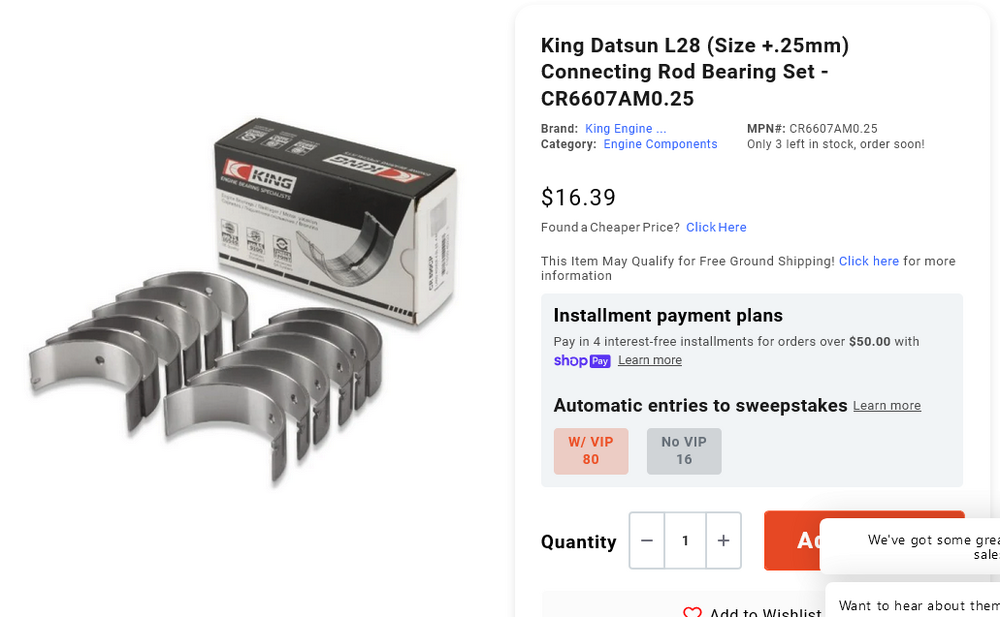

Rod and Main Bearings

Check this... Found it while looking for what I had paid for mine. Apparently they have three in stock and are selling for less than I paid. https://throtl.com/products/king-rod-bearings-kingcr6607am0-25 LMK if something blows up and you still need mine.

-

Rod and Main Bearings

Sorry, just circling around to this. Yes, I am happy to help. Let me see what they cost me and then I'll PM you. Are you in a hurry?

-

Rod and Main Bearings

I was able to put my hands on the rod bearings with relative ease. I'm still in the middle of moving everything into the new shop, so it's a bit of a cluster. If you need mains, lmk and I'll look more.

-

Rod and Main Bearings

I have some new King bearings I will not be using. I'll check tomorrow for the undersize.

-

Rod and Main Bearings

What, if any, is the oversize you need?

-

Rod Bearing Wear pattern (1975 280z)

I guess I have a different take on the bearing. I see that some foriegn material has been fed through the oiling hole that has scratched the surface of the bearing at its midline - not terribly, just notably. The filter should have snagged that but either didn't get the chance or it occurred during a bypass event. Also, it looks like the bearing has spent some time without an oil film between it and the crank, hence the polishing/removal of the bearing liner material. Oddly though, only the bearing edges are worn - not the middle and the wear area seems narrow. I would expect to see that wear pattern uniformly across the bearing surface and involve more of the circumferential area. I like @Racer X's suggestion of either bronze gear failing.

-

Percussive Maintenance

I used to work in a development lab for telecomm equipment. We were the go-to folks whenever anyone had trouble with their monitors, test equipment, etc. One guy in particular was quite good at getting failed equipment back up and running quickly. His technique? Smack it hard as you can with an open palm. It worked way more often than not. Thanks for a good laugh early in the morning.

-

Parts Wanted: Need A Good S30 Hood

I have one you might be interested in. It came off my 76. It has no damage at all. It's problem is that the local blaster/powdercoater gave it some slight waves while stripping my car. So while it looks normal, it will need some flattening either with tools or filler. If you need better pics let me know.

-

Dead spot in steering, where to look?

Years ago I found a service place that catered to Porsche enthusiasts. I needed a bolt-plate alignment (aot to the typical concentric cone style). I think the cost differential was $25 vs $5 per wheel. Yeah, it was painful, but the car became a dream to drive afterwards. Prior, it acted like the front end was going to explode above 50 mph.

-

Oversize Pistons

I found them on Greenline Motorsports. I think they said 2-5 months delivery.

-

Dead spot in steering, where to look?

If the rack is worn, there'd be excessive right and left motion of the steering wheel with no movement of the wheels. You could compare the amount of movement of the steering wheel while the wheels are straight and also at the right and left locks for a clue as to the extent of wear. If the play is similar at all three locations, the problem may well go to another component - tie rod ends, (or as @dutchzcarguymentioned) differential air pressure, different tire tread patterns, any of the three alignment variables, etc. You mentioned you had a concern with a shop's possible non-understanding of how to properly align the car. How do you know the last shop had a clue?

-

Oversize Pistons

I believe I've read the DS pistons are rebadged Kamearis. Just checked the price: $1375. I figure as soon as I read off my credit card number to TEP, someone will start selling great cast pistons for $300.

-

Oversize Pistons

That's why I had asked if they were new. My next question was going to be WHERE DID YOU FIND THEM? I'm in the same boat. Need .50mm over. JE Pistons will sell forged pistons direct to you for about $200 each, and Top End Performance will sell you JE Pistons fully and correctly configured for $1300 a set. You can bore ($200) to 1mm over and get Ross for $900 (IIRC), but they seem to not get much love, while JE's seem to be loved by "all". Finally, you can also get Kameari from Japan for under $900, but not in .50mm over. I've been looking for more than a year and am getting uncomfortably close to being okay with $1300 for a set. My engine has had rods conditioned (shortened), the head has been cut, the block has been decked, it has a performance cam waiting to go in, and I am specing 10.5CR. I figure $100 delta for TEP to guarantee proper configuration is worth it; and by getting JE custom made, it obviates buying Cometic or Kameari head gaskets at $200 to get the CR. This is all a lot of fun. I had budgeted around $200 for cast pistons. 😢

-

Evap Hose Grommet 17384-N3700 - Early '76

- 5 downloads

- Version 1.0.0

This is a 'functional' replacement and is not intended to appear as OEM. The part was printed at .20mm using TPU. I designed it using a badly deteriorated sample, so it may need some tuning. The old and new appear to match well - but the new part has not been tested on the vehicle. If you print it and find it could use some tweaks, please let me know and I will dial it in.Free -

Oversize Pistons

Are they new or used (or NIB)?

-

Most dreaded of jobs finally on the horizon ? the fuel tank !

I was all set to use a sealant as a precautionary measure, then decided to cut open the tank bc of some significant denting in it I couldn't resolve otherwise. Sure glad I did. The pick-up tube has a VERY fine mesh screen inside a baffle that I had never before seen nor heard of. I suspect the sealant would have done a brilliant job of sealing up that screen as well as everything else it is supposed to do. Tank is from early production '76 280

-

[2022] What Did You Do To/with Your Z Today?

I am repeatedly amazed how many people will share a personal story with me about their experience with a Z. Either they had one or a friend did. And the stories are pretty similar - fast, fun, and way cool.

-

280z Steering Wheel Vibration

I also have chased the elusive, speed-sensitive steering wheel shake. The problem came directly from a wheel-balance problem - BUT! it's not as simple as just rebalancing. The problem was the wheel weights were not distributed symmetrically about the imbalance. Since any balancing process will never be absolutely perfect, the slight inaccuracy of this particular balancing effort worked very well up to about 55mph. Above that speed, the car acted as though it would explode. Definitely hit a resonant frequency. If the weights had been selected and applied more carefully (shall we say?), the inaccuracy would have been significantly reduced. In the end, a perfectly acceptable balance was achieved by using bolt-plate balance fixture as oppsed to the typical centered balance fixture. The difference being each wheel is balanced based upon its mounted center.