OK, I promised to describe how the gauges work... Not sure it should be here in this thread, or if I should start a new thread for this. I'll put this here for now, but if people think it should be separate let me know and I'll start a new specific thread about gauge theory.

So in order to understand how the gauge system works, I think it would be a little easier to first understand how they DON'T work. I think everyone already has a good handle on this simple system, but it's an important place to start.

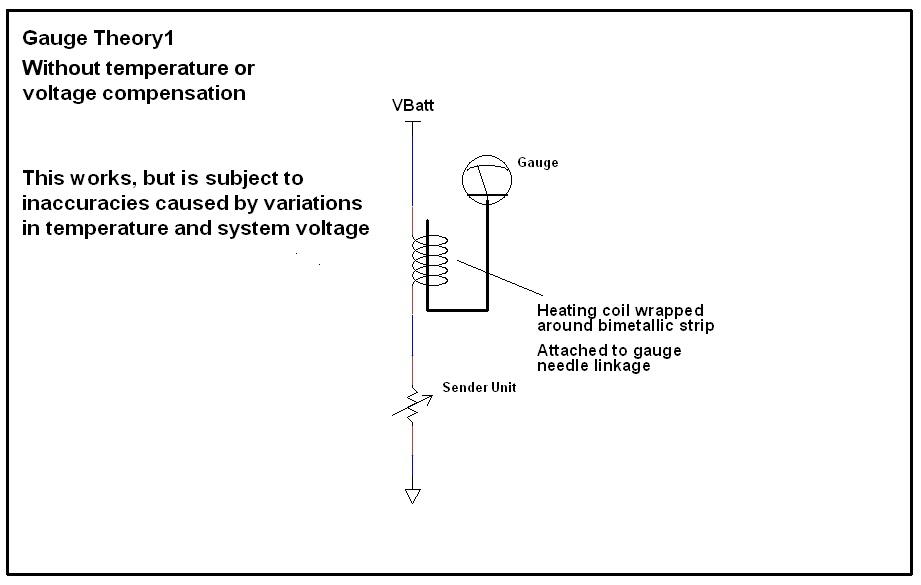

Here's a pic of a simple (uncompensated) gauge design. Wrap a heating coil around a bimetallic strip and mechanically attach that strip to the linkage of a gauge needle. Flow current through that heating coil and to a sender unit who's resistance reflects the level of whatever you're trying to measure (temp, oil, fuel, whatever).

As the resistance of the sender unit changes, the current through the heating coil changes and that changes how hot the bi-metallic strip gets.

The lower the sender resistance, the higher the current.

The higher the current, the hotter the bimetallic strip gets

The hotter the strip, the more the needle moves.

Here's a pic:

This simple uncompensated gauge system does "work", but it is subject to a few real-world outside influences that can affect the accuracy:

First, since the whole thing works on the temperature of the bimetallic strip, the gauge will read differently on a hot day than on a cold day.

And second, since the gauges are powered by the battery system of the car, changes in that system voltage will affect the gauge readings. The gauges would read differently sitting with the engine off than they would with the engine spinning at 3000 RPM when the alternator has kicked up the voltage a bunch. The system voltage can vary from about 12V to over 14V and the gauge readings would change as the voltage varied.

So the basic gauge system above sorta works, but these two real-wold effects are undesirable. If the above basic gauge system makes sense, I'll get into how they compensate for those two real-world effects.