-

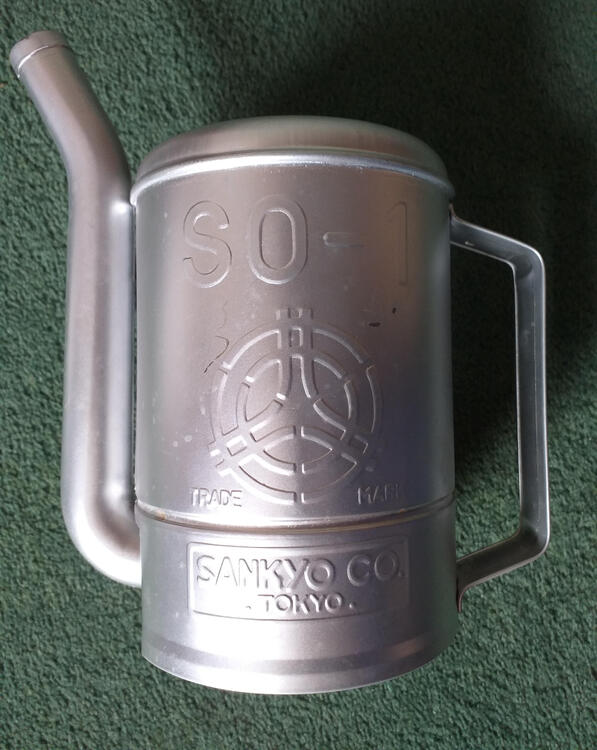

Period Japanese oil can

-

RIP260Z started following s30z front on a 180sx , Period Japanese oil can , Hose Clamp Finishes and 2 others

-

Period Japanese oil can

I try and not get too distracted by this type of genre of collecting, but this was new, and cheap, and I had other parts in Japan waiting for shipment, so... What is great, is the spout pivots at the bottom, thus changing the spout angle, aiding pouring. Made of metal, I don't know its age, but I suspect more towards the 1960's rather than the plastic 1970's... Enjoy

-

Hose Clamp Finishes

Not that its a huge amount of info to go on, but I got some NOS hose clamps which are correct fitment for the 520 truck heater, in their bag, and they are clear/plain zinc. I'm working on a different era of hose clamps, period mid 1960's for the CSP311, and it seems Nissan was in the midst of changing and constantly changing, thread, head and style of clamp, and for different places on the car. I think its also a moveable thing through the S30 pruduction years.

-

My two swiss S30Z Fairlady Restoration build thread

The Mikuni gasket kits (US) don't have in them the pump diaphram, did you get those separately? https://www.jauce.com/auction/1155785394 This what they look like if you don't know. From my experience the gasket kits from Japan do/more likely do come with the pump diaphram than the US kits.

-

My two swiss S30Z Fairlady Restoration build thread

The texture is what's left after the serious corrosion on the trumpets was removed, not from my work. I could have changed the trumpets out, but the other carb has a cut-away on the trumpet particular to a car model, so not something I wanted to try to replicate, therfore let someone else change. I strip the carb, thread holes cleaned with the correct size tap, everything goes in an ultra sonic bath (with plenty of soak time without ultra sonic [I have some laboratory neutral detergent]), cleaned, dried. Blasted (wet) as its easier on the surface (not with anything really abrasive), cleaned, dried, checked. Steel parts get the same treatement before yellow zinc. New genuine gasket kits and replacment parts, esp idle mixture screws replaced wether needing or not (as a groove can get worn creating inconsistent idle). Its quite a bit of work, takes time.

-

My two swiss S30Z Fairlady Restoration build thread

Nice Nils! These are type 4 PHH 44's, there are different types, and gaskets differ a little. I restore and rebuild these in my spare time, so by the time you replace all the gaskets, its essentially a strip, clean and rebuild. The pump diaphram at the bottom of the carb is where most of the crud sits, and the diaphram is worth changing. I find them a nice project to do. Here is my before and after;

-

Datsun 240z 1971 (feb) windscreen wiper mechanism parts?

Nissan did make wiper blades for high speed, I have a pair NOS for the 510, with a blade to help with downforce. Though unsure if there were Nissan ones for the the S30, without checking. Yes, a common problem with the wiper mechanism, slow and not setting back, most swap to the Honda(?) wiper motor, but a through clean and re-grease may do the trick.

-

Sports option diff cooler

-

Sports option diff cooler

Spotted this Sports Option diff cooler and pump. Thought it would be interesting for some. @HS30-H can you say anymore, pump under rear floor mounted, bolt holes already exist? The auction listed it for the Fairlady Z.

-

Datsun-240z Vs Fairlady-z432

Hi Kats, Unfortunately the shipment of the spray cans was cancelled shortly after placing, even shipping by sea from Japan looks not possible.....

-

Datsun-240z Vs Fairlady-z432

Sucessfully ordered from Japan! Shipped by sea. More than 1, as min number could be ordered from supplier....

-

Help ID brake calipers

That's what I have just done, I don't need now, but as its cheaper now, and I had no shipping cost (in with parts bulkier/heavier).

-

s30z front on a 180sx

Spotted this on my Yahoo trawl.... https://www.jauce.com/auction/w1150380520

-

Help ID brake calipers

Jeff, I pointed out these retaining rings in post 40, here is a link; https://www.jauce.com/auction/w1147945499 Unless H30-H or Kats know of another place the get original or someone else who makes these, velo1955z is the only place I have found. I have another set of rings arriving today from Japan.

-

Help ID brake calipers

True, but sites like Jauce let you buy NOS parts and other rare parts, if you want, like I do, its the price that needs paid, otherwise there wouldn't be any restoration.

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

.thumb.jpg.e06be5882689529a28f7380773a10dd1.jpg)