I am one of the many Z owners, with SUs, that has battled a lean condition on hard acceleration, or WOT. My idle and cruise AFR readings (have AFM attached to header) are great at 14.5 or so, so have adjusted it as best as i could. Along with SM needles, I adjusted fuel levels and tried to do anything I could think of to resolve this issue, to no avail. I even switched to triple Webers, which allowed me to see how my car could really perform with appropriate AFR! I decided to switch back to SUs, as I had some linkage sticking and fuel dripping that bugged me.

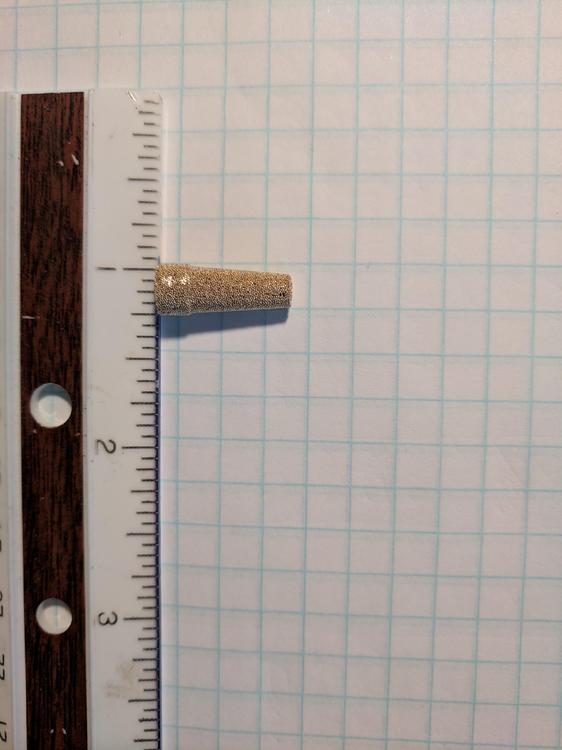

So, I started looking into the different available SU needles to see if I could find something richer. I looked at various charts and saw that the SB needle had the same configuration at the top two levels (so idle is the same), and was slightly richer heading down the needle. I thought, let's give it a shot! I could not find anyone locally that provides SB needles, so I went down under to Australia and ordered a set of SB needles from Competition Products for about $40 delivered (less than 2 weeks for delivery).

I was stunned at the improvement! My idle and cruise AFR remained around 14.5, but my lean (16 to 17+ AFR) condition at WOT was gone, now hitting around 13.5 AFR!! That is ideal! I cannot believe the difference. My L28 was rebuilt with flat top pistons years ago, but outside of that, there is nothing else outside of the norm.

I would strongly recommend this solution to those with similar issues! I strongly urge you to make sure your fuel level (and flow) is appropriate before you go this route, as that can resolve many of the lean issues.

.thumb.jpg.cf72bc353f406703497db1fa66ff30c8.jpg)