Racer let me know if you can see this post ok?

Another long day of drilling out spot welds on the roof skin. I can see why metal works are the most expensive part of restoring a car, it’s so time consuming.

can anyone tell me about the joint between the rear quarter and roof skin? Mine seemed to be oxy welded or brazed together, is this factory? There was lead wiping which I burnt off, I ended up cutting the joint with a grinder but wondering if there’s a better way.

I also found the front corners were welded in, there was no other way so I just cut joint and part of the skin with my 5 inch, I really must get so Roloc attachments and small cutting discs for my die grinder. I managed not to damage any structures underneath.

i found the front and rear of the roof skin easy to unpick, the LHS was just cut as there was barely anything left, I found the RHS rain rail joint extremely difficult to unpick, I came close to just cutting it with a grinder on more than one occasion, but I persevered and I’m glad I did. There is just no room to work, I tried modifying my scraper blade so I could hammer it along as I went, but that wasn’t effective. In the end I used a sharpened flathead screwdriver to break the joints after drilling.

there was a small amount of mangling which was unavoidable but overall very happy with how cleanly I was able to unpick the roof. I’m hoping to sell the skin to someone who needs to fill in their sunroof hole as the center of the skin is excellent.

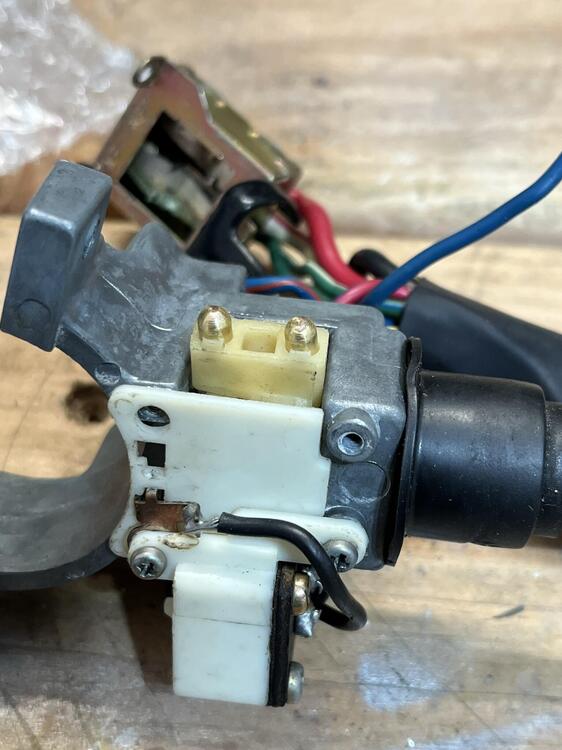

Was surprised to find the RHS to be very clean, some pitting at the rear quarter joint but overall a good result.

the LHS is a $^!# show, as expected, it’s going to take a lot of work to rebuild the whole structure, rear quarter join is completely gone.