My experience was quite the opposite when it came to the Flat Tops

While some like to debate the technical merits of the Flat Tops - one thing is not debatable. From the introduction of the 1973 240Z’s with the Flat Top Carb’s needed to met the EPA Exhaust Emissions Standards - Dealers were plagued with Customer Complaints accompanied by Datsun 240Z’s being returned to the Dealerships on a Tow Hook. Something never before experienced and most certainly never expected. The 240Z and indeed DATSUN had established a well deserved reputation for Reliability second to none.

I was there at one Dealership and it was NOT PLEASANT for anyone, most certainly not the New Owners, nor the Service Managers that had to tell the Customers their car might be in the Service Bay for several days. Of course the Customer Complaints came back on the Sales Staff as well. Several Customers demanded that we refund their money and take the car back.

The Flat Tops were so good - that Nissan Motors spent thousands of hours of Technical Service & Engineering time trying to identify and solve the problems with the Flat Tops both here in the USA and in Japan. We had Nissan Personnel in our Service Dept., working with our mechanics, several days per week, for several months. This was happening at 2 or 3 other Datsun Dealerships that I was aware of on the West Coast as well.

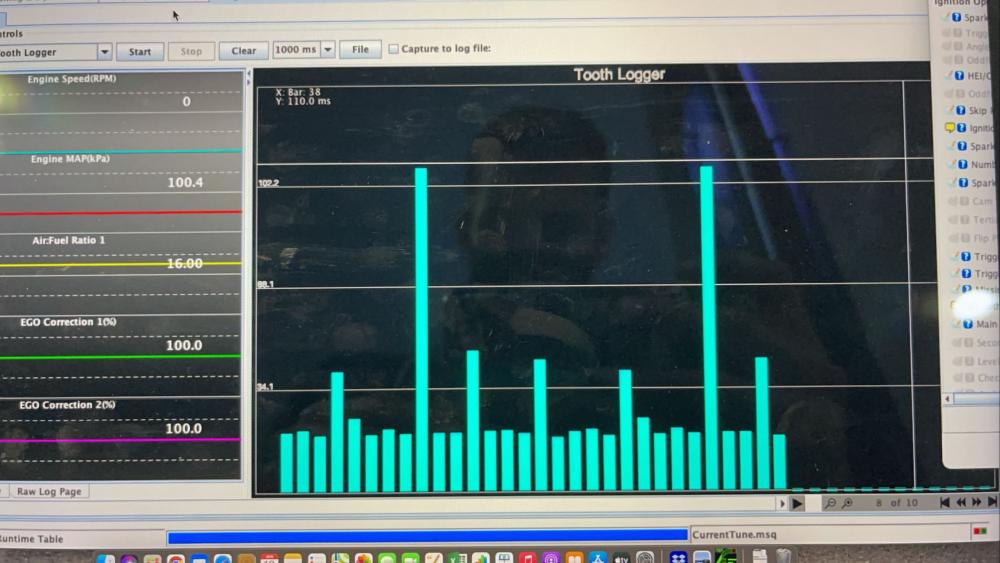

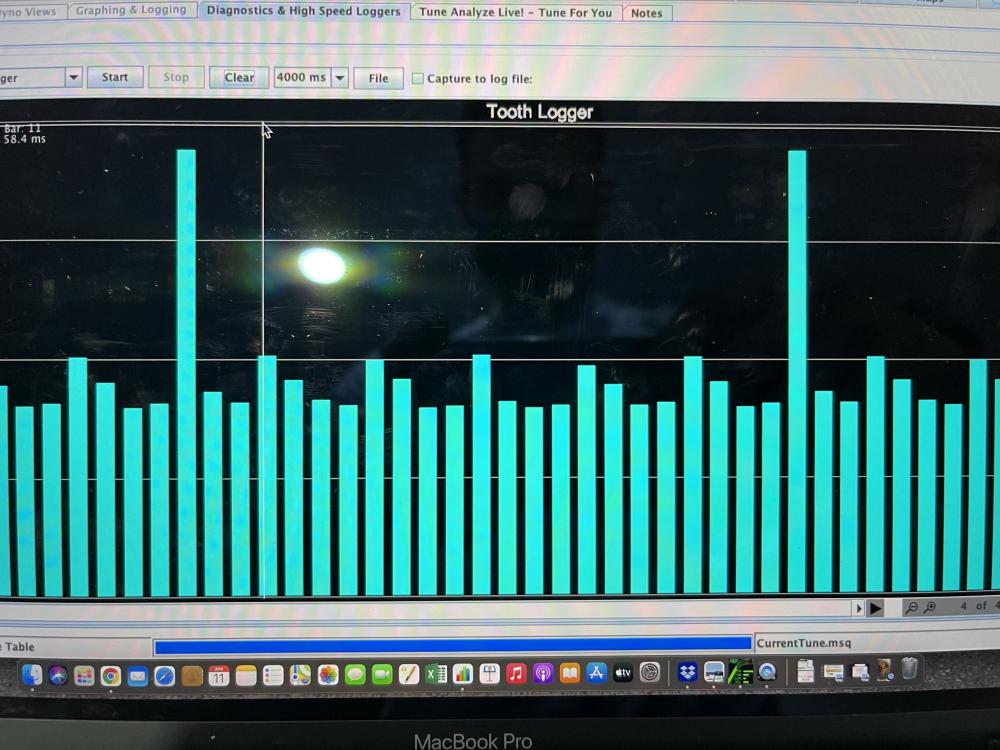

Indeed we saw an ongoing series of modifications attempted while looking for an actual solution to the problems. A lot of Trial and Error went on for months. The problems according to Nissan were Vapor Lock in the fuel lines and Percolation of fuel in the float bowls (now hanging directly over the larger and hotter exhaust manifold). The attempted solutions were many and varied for months and months. The result were Z’s dying on the street or highway and/or refusing to restart when hot. It was not unusual for a Customer’s Z to be returned to the dealership 3, 4 or 5 times before the Customer gave up. (then went to Private Repair Shop and had 70/72 SU’s put on - problem solved).

By the end of the 1973 Model Year, Nissan had greatly reduced the occurrences of the “problems” - but far too many Customers in several area’s of the Country were still being effected and/or were disappointed.

Nissan’s real solution to the wonderful Flat Tops was to replace them with Fuel Injection as soon as possible. For most customers, and secondary owners - the Z’s were out of Warranty after 12 months/12,000 miles - so any/all labor spent attempting to “correct” of “fix” them held the potential of significant Labor Costs for subsequent owners - their least expensive solution was to replace them with the 70-72 SU’s.

By the time the 74 260Z’s came out - Nissan had made several changes to the Flat Tops and they did perform far more reliably - however outside of the Datsun Dealers, the privately run shops did not have the benefit of Nissan’s Extensive Technical Training offered to the Dealer Service personal, nor did they have all the Technical Service Bulletins the Dealerships had. So private shops just refused to spend the time with the Flat Tops - because their Customers weren’t willing to spend the money on the labor hours needed to overcome the learning curve. The “learning curve” consisted mostly of trying to get the technical information from the Dealer Service Departments (who really weren’t in the business of training their own competition).

This was not a situation where untrained Service Tech’s did not know how to deal with a new Carb. - it was a situation where the new carb. properly tuned to meet the EPA Spec.’s at the time - would not perform on the car. A year or year and half later, with the new Carbs redesigned / modified yes, the Nissan and Dealer Trained mechanics could set them up and yes they would run (most of the time).

Mr. Umera tells the story in his Book: Section: Post Sales Responses - Vapor Lock

-Quote:-

Executive Director Ryoichi Nakagawa, the chief of the engine departments, gave us a pep talk, saying, “In a car, the worst case that can happen with this defect is the engine stalling, but if this happens on a plane, it crashes.” Although the engine design departments also tackled countermeasures, satisfactory results were not obtained, and the manager Harada of the Third Design Department asked us to cooperate in coming up with countermeasures for the vehicle itself.

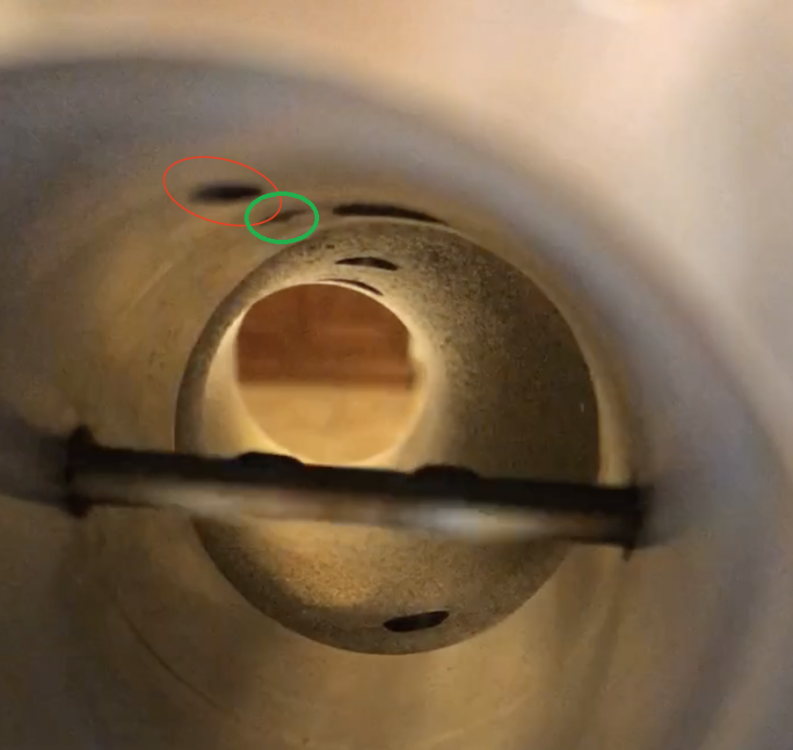

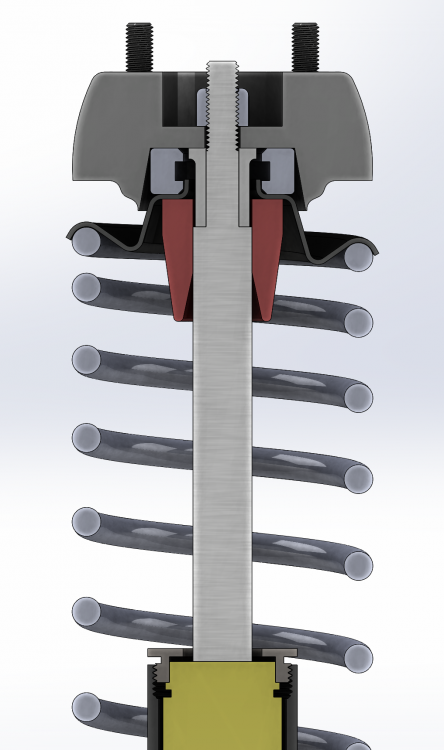

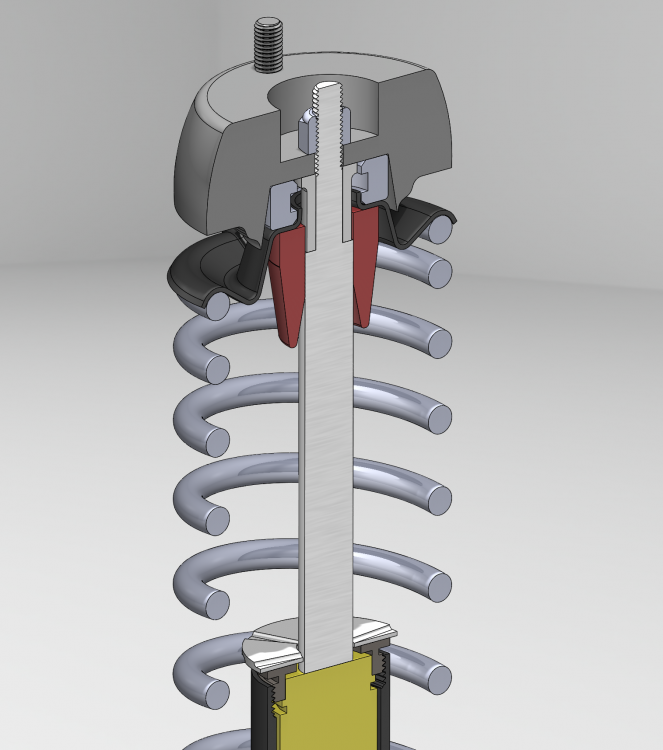

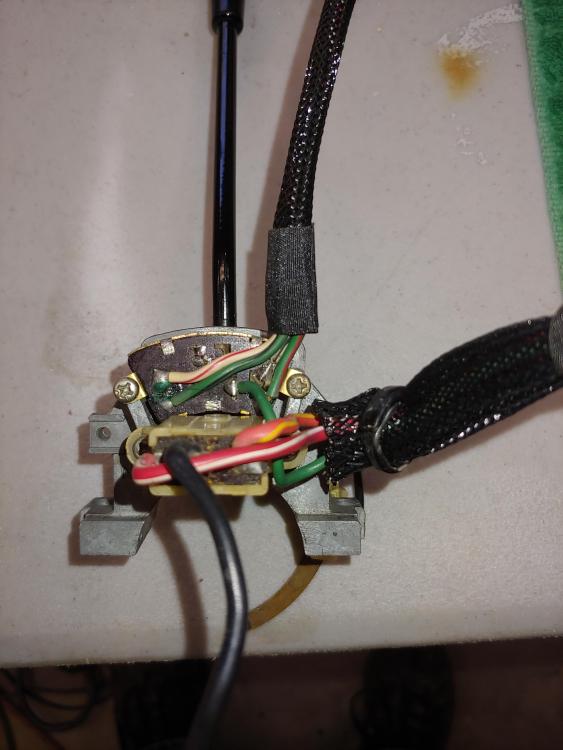

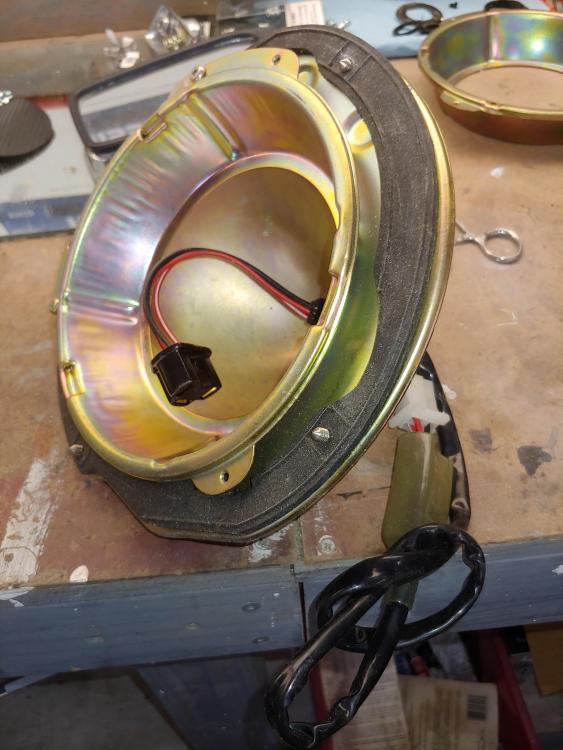

As a temporary measure, a heat shield plate was placed between the exhaust system and the carburetor, glass fiber was wrapped around the fuel system pipe, and louvers were cut in the engine hood to vent heat. But this was not enough.

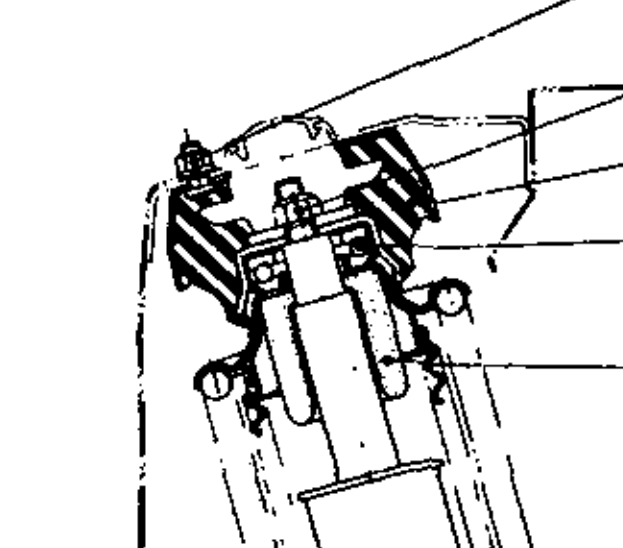

Then, as the last resort, a powerful sirocco fan, which began to turn when the temperature in the engine room rose above a given temperature, was installed in the engine room to pump out the heat. This almost solved the problem, but it was never perfect, because the fan would turn for a while or sometimes started turning suddenly even after the engine was turned off, surprising drivers.

Assistant Department Manager Shidei, who was the chief engineer at this time, visited America to persuade Nissan Motor Corporation U.S.A., to deal with the problem using this tentative measure for a while until a proper countermeasure could be taken. I can’t imagine that would have been an easy task for him.

One year later, we solved the problem properly by abolishing the carburetor and adopting the L28 engine with electronic fuel injection.

-End Quote-

FWIW,

Carl B.

Subscriber

Subscriber 5Points11,142Posts

5Points11,142Posts