Ah, engine build day is finally here! All these months of preparation and cleaning all come down to this.

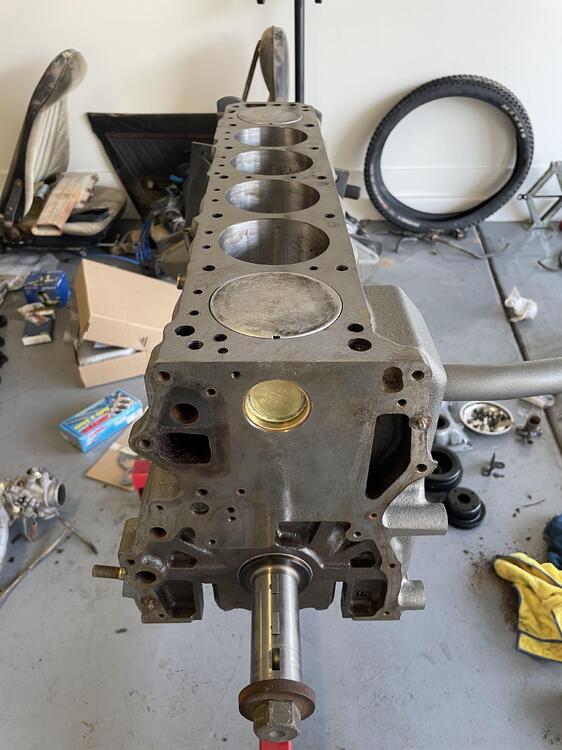

The block was hot tanked, honed, and decked. I first started with a cleaning and removing the original expansion plugs. There was a heavy amount of rust within the coolant passages and some left over crud from their cleaning. I let the water run through these until no more particles were coming out. I ran a bristle brush back through to loosen anything up and another wash. I'm sure I missed the deepest corners and crevasses but I will just plan on an early coolant flush.

All taped up and ready for paint! I had back and forth's on which color I wanted to go. Blue, black, silver, iron, or something wild like an orange. Ultimately I went with Iron to keep things simple. Sorry purists!

After a few coats of primer and paint, things are looking much better. New expansion plugs really look good 😍 My kit from Rockauto was 2 plugs too short. So I had to swing by and get 2 extra 35mm plugs.

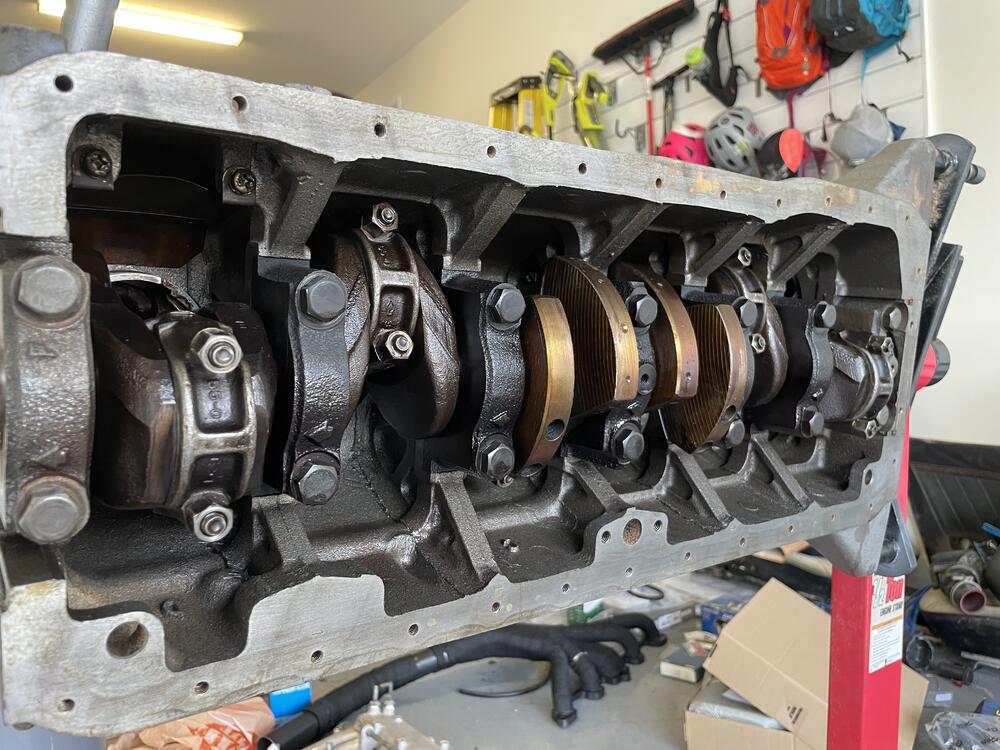

Up next was bearings, crank, rings, and pistons. I did this late at night and realized I didnt even take photos until everything was in! Anyways, it went extremely smooth and the only hiccup was my dummy head rushing into it. I put the wrong sized main bearing onto the rear cap. Not until I got to the last two caps did I realize my mistake. Luckily I found this mistake and was able to correct it.

Everything is turning smoothly and feels great. Ah, the sounds of fresh rings is the best. The friction of the fresh rings is perfect. Up next was the ARP head studs. Its so odd that they are hand tight for the studs themselves. I get how the clamping force works...but it feels so wrong!

Slapped on the fresh head. So glad to get this thing off my workbench! I ran into my first roadblock here as I needed a deep 12mm 12 point socket. So that was all for day 2.

Day 3 started with a quick trip to grab a new socket and get those head bolts torqued. Installed a new timing set. Seems almost too easy to time compared to DOHC cars Im used to! This photo was taken right after placing all the guides, but I didn't notice until placing my gaskets that my slack side was a bit off. So I repositioned it for a smoother transition.

Covers were next on the agenda. Things are moving fast now!

Lastly was the oil pan, oil pump, water pump and pulley, thermostat house (ITS SO GROSS 🤢) and the manifolds. I had to take a shot of just the exhaust as it looked so good! Installing the oil pan gasket was a a pain. Im not sure if the kit I ordered was wrong, but the gasket looked small. It was flexible so I thought that maybe it just need stretch to fit. I had 3 corners locked in place but could not get it stretch enough for the fourth. Not sure what the deal was but it ended up tearing. I picked up a Fel Pro gasket and it fit much better. I feel way better about it now.

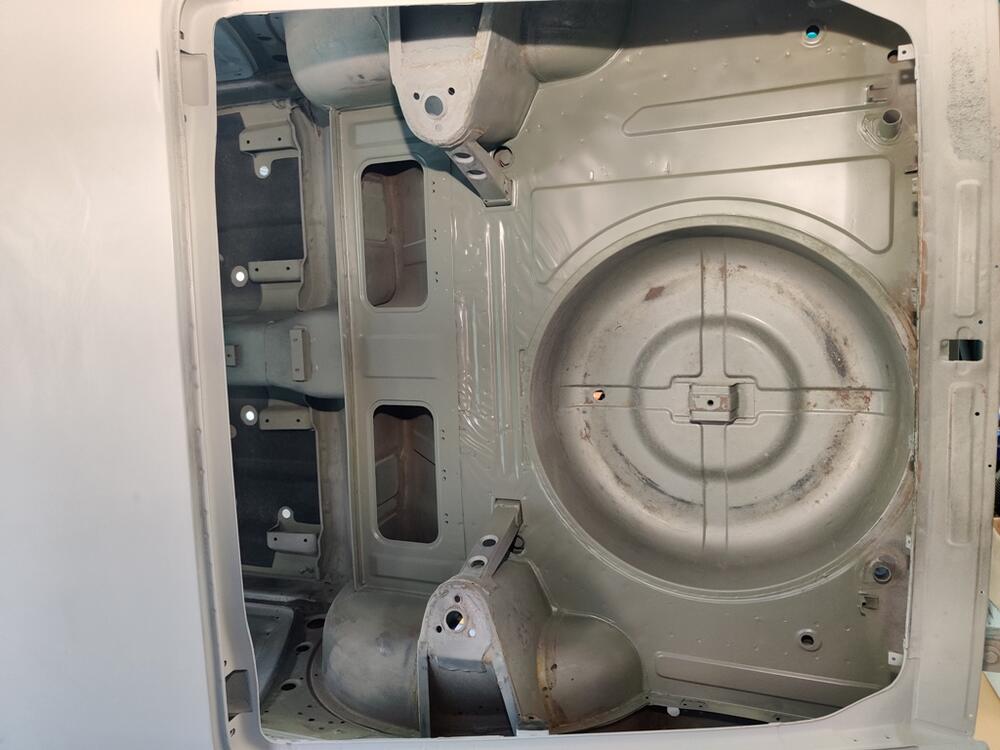

Not picture is that I also had the intake manifold installed. I am still needing a few misc plugs and I need to create a block off plate for my cold start valve. That thermostat housing...just needs replacing. I hate it. Tomorrow I will move my attention to the transmission. I am waiting on the input seal to arrive so I am at a standstill until then. The anticipation is growing!!! Let just take a moment to remember where we started with this crusty piece 🙂