-

Speedometer pinion stuck

Thanks for the suggestions. I'm worried about damaging the speedometer cable by pulling on its. I'll give it a try. I might try and find an old speedometer cable and improvise a pulling tool.

-

Jeff Berk started following Any Black Friday Sales Worth Noting? , Speedometer pinion stuck , New Fuse Box To Replacce Fusible link Holders and 1 other

-

Speedometer pinion stuck

I have a slight leak at where the speedometer cable connects to the transmission. I ordered some seals but I'm unable to remove the pinion to install them. I removed the metal tab that holds it in place and can twist it with a lot of effort with a pair of channel locks (without damaging the threads) but only in one direction and it does not move out. I looked at this video but it wasn't too helpful: Can anyone offer a suggestion? Maybe thread something onto the threads and use a slide hammer or something to tap it out?

-

New Fuse Box To Replacce Fusible link Holders

I don't know what others are using but I installed a pair of marine brakers on the firewall.

-

Paint protection film

I would think plastic film, regardless of material, would be more prone to being scratched than glass. The mohs hardness scale (used to describe hardness of minerals) lists glass as 6.5 out of 10. A steel knife is 5.5. This means that glass can scratch steel but not the other way around. Unfortunately quartz is 7 so if you are at the beach, be carful how you wipe the sand off your windshield. Sorry for the earth science lesson, I'm a retired geologist.

-

Diff cover looks great, leaks as fast as I fill it. I'll try again this fall.

A few months ago, I created a differential cover to go with the KAAZ LSD I installed last year. I finally got around to installing the cover and as fast as I filled it, the gear lube leaked out. I'll pull the cover and see if I can figure out what I did wrong but for now, I'm going back to the original cover for now. I'm guessing there is a problem with the mating surface. I'm not necessarily posting for advise as much as I need to vent. Hopefully my other little projects worked out better so I can get my Z back on the road. Other projects I'm finishing up include a freshly rebuilt 5-speed, oil pan gasket to stop the oil leaks (I hope), DIY engine splash shield, and fabricating plastic inner fender covers.

-

Any Black Friday Sales Worth Noting?

Those tail lights are very cool.

-

Any Black Friday Sales Worth Noting?

I've had a dash cover in my cart for about a week in anticipation. Its either going to be installed or used as a form to make a leather dash cover (attempt #2).

-

Any Black Friday Sales Worth Noting?

I'm answering my own question, I just got a 10% sale announcement from Z Car Depot THIS FRIDAY 11/29 TAKE 10% OFF YOUR ORDER FOR OUR ANNUAL BLACK FRIDAY SALE! DISCOUNT IS AUTOMATICALLY APPLIED AT CHECKOUT

-

Any Black Friday Sales Worth Noting?

Hey All, Is there anything Z related on sale this week worth looking at? Jeff

-

1976 280Z Restoration Project

This is a long thread so hopefully this hasn't already been addressed. The Japanese battle flag on the inside of the hood... Is that painted on or is it a vinyl film? I wanted to cover my hood's underside with a printed graphic but I'm concerned about heat damage. I know my engine compartment get really hot.

-

KAAZ R180 LSD fit problem

Here's an update. I finally got to an Autocross last weekend to try out the LSD. I was delayed by a brake issue that kept my 260z up on blocks for a few months. The thermistor I installed in the differential drain plug did not show a significant heat buildup during the autocross. The temperature reached about 110F. The interesting part was that during the drive to the event, I drove at 70-80 mph for about 45 minutes. That built up a temperature of 230F. The KAAZ tech warned me that above 200, the oil will begin to break down. I may need to install that finned diff cover which unfortunately means I need to modify some other components to get it to fit.

-

Help ID brake calipers

So far so good... I took the Z out for an autocross event last weekend and the brakes worked and didn't leak. I also talked to my local Z mechanic that I fall back on when I get stuck and he commented that if I'm not driving my car in harsh conditions, I likely didn't even need the boots. He said that his cars with Wilwood brakes don't use them and sure enough, when I looked up Wilwood rebuilding kits, boots are not included.

-

Need picture of missing part

Would anyone be willing to do a 3D scan of the convex side of one of these? I think I can create a left and right mold from this to try to vacuum form these. Scanning can be easily done using a cell phone with the free version of the KIRI Engine app installed (https://www.kiriengine.app/ ).

-

Need picture of missing part

The asking price for this part seems very lofty. If I can find one that I can scan or use to make a mold, I think I can churn out a few possibly using a vacuum form method. I've never did a vacuum form (excluding back when I used a toy in the 60's), but I have a unit available nearby.

-

Need picture of missing part

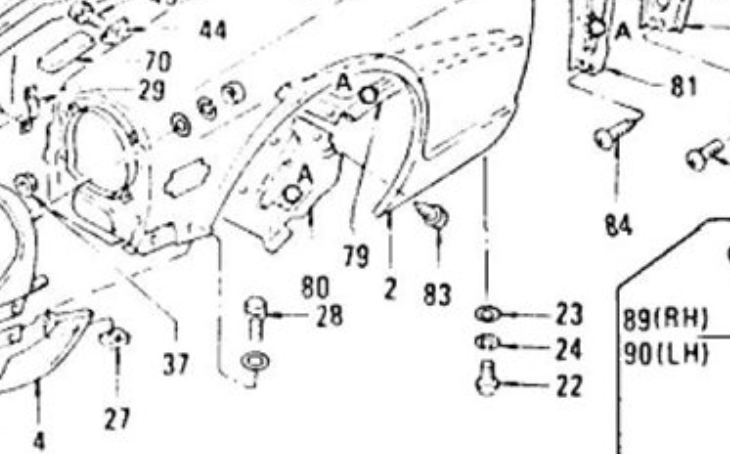

This was a April 1974 260z so I would of thought that it would of also been on some of the 240z's. If its part No. 63830-N3600 and 63831-N3600, then it looks like you are correct that its a 260/280z part. Maybe that will make it easier to locate. I think the part I'm looking for is 64186-N3600 and 64187-N3600 that is identified as part 80 on the diagram. BTW: I finished my caliper rebuild so after nearly 2 months of waiting on some parts, I can drive this thing for a few weeks before it goes into hibernation.

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber