The head Cliff posted isn’t an L series 6 cylinder head, looks like a 4 cylinder head.

Still, the sequence is similar, starting in the middle and working out.

The maximum torque is a range because the head bolts are torque to yield bolts. Since the head has been on the car for so long, you don’t need to go through the stepped sequence of torque values. Also, given that the bolts are tty, it is better to set your torque wrench to the lower end of the maximum range, at 54 ft lbs. Your looking for a loose bolt, not installing a fresh head on a new gasket. I have found broken head bolts this way.

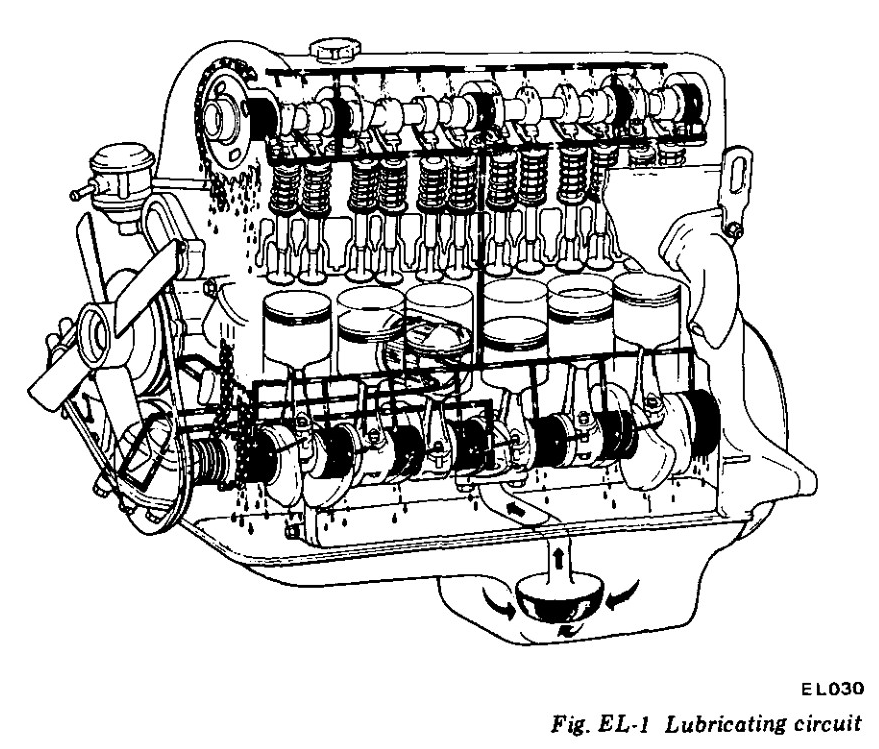

But Zed makes a good point. The oil passages are on the right side of the block and head, and the engine is leaned to the right, about 12 degrees or so.

It would be a good idea to check the cam cover bolts for proper torque before taking it off.

Also, don’t use a cork gasket. They leak before you even put them on. An OEM or equivalent gasket, with no sealer. Torque the bolts, and it should not leak.