Well we're back again, its been another busy but productive weekend. I'm pleasesd to say that the car now has a fully functioning forced cold air intake fitted!

I just wanted to start by giving a shout out to Richie, I completely hijacked this setup from his recent work and used his suggestions and parts list to make this possible. It goes without saying that this setup is entirely custom, with all of the parts having been sourced from ebay with the exception of the airbox from MJP (this effectively comes in flatpack form though). This setup previously seems to have only been used on tripples rather than SU's from what I've seen to date though...

First up was to protect the airbox itself, arriving in naked firbreglass it looked a bit dull and looked like it would benefit from some protection. Also the lip of it was white in places from the raw finish and gave it a rugged look, having gone round with a black shapie everything was blacked up to match in. Following a quick degrease and a few coats of laquer using a rattle can in the garden the results the next day were much better and give it a more premium finish.

Saturday afternoon started by getting the carbs back to basics to allow me to get in with some masking tape to make a transfer outline of the bolt holes and carb intakes before transfering this across to a cardboard template of the airbox. Having carefully cut this up I could test fit the cardboard for fitment until I was satisfied, with that done I transfered the outlay onto the airbox backing plate marking it up with a Chrome Pen. So as to not rip the fibreglass up, a dremel was used to drill around the areas before opening up the gaps annd sanding them back to get the desired fitment. This was a bit of a sod and took some patience as you only get one shot to get it right.

With that done the rubber sealing trim was installed and the clips/brackets that secure the airbox offered up for positioning and drilling, being patient with the dremel and drill got all of the holes in place. These has now been locked down using M4 Bolts and Nylocks on the inside to give a flush fitment and cause the least disturbance while remaining removable. Long term if there's no issues, I'm still tempted to move to rivets however we will see.

Come Sunday, next up was taking the CRX induction pipe to mark up and chop up using an angle grinder. With my small one out of action the hacksaw came into play as the 9inch grinder I had turned out to be too man for a precision job. This was a case of more patience and conservative cuts to get the desired length (I still think the pipe may be a tad too long with the airbox being very snug pushed up against it). In order to hold it in place a silicone joiner hose was inserted through the bulkhead, this was an absolute just fit and had to be heated in hot water to be made pliable enough to slot in place and is now going no where. With alot of squeezing the ali pipe was dropped in place with some pushing, pulling, cursing and swearing before being tightened up using jubilee clips.

With all of that done, all that was left to do was cut the 90 degree bend pipe out of the front to fit up a suitable cone air filter, the pipe was a bit too heavy duty so took some time with the grinder but seems to have done the job. This slotted in place with jubilee clips and has had a generic ebay red 3 inch cone filter added onto the end. Having covered it in K&N filter oil it looks to be more than up to the job of keeping out all necessary debris and flies etc. Only time will tell how durable it will be!

Overall it seems to be gone very well, its snug but has good clearance in all of the right places. I may cut down the pipe from the airbox to the bulkhead to allow for easier fitment and removal going forward however its ready for the shows this weekend. Having taken it around the block it seems to be running smoothly however the extended roadtest of a couple of hundred miles should reveal all. Fingers crossed I can get it to a Dyno soon to have a proper tune up and see what all of our hard work has gained us, the performance certainly seems stronger.

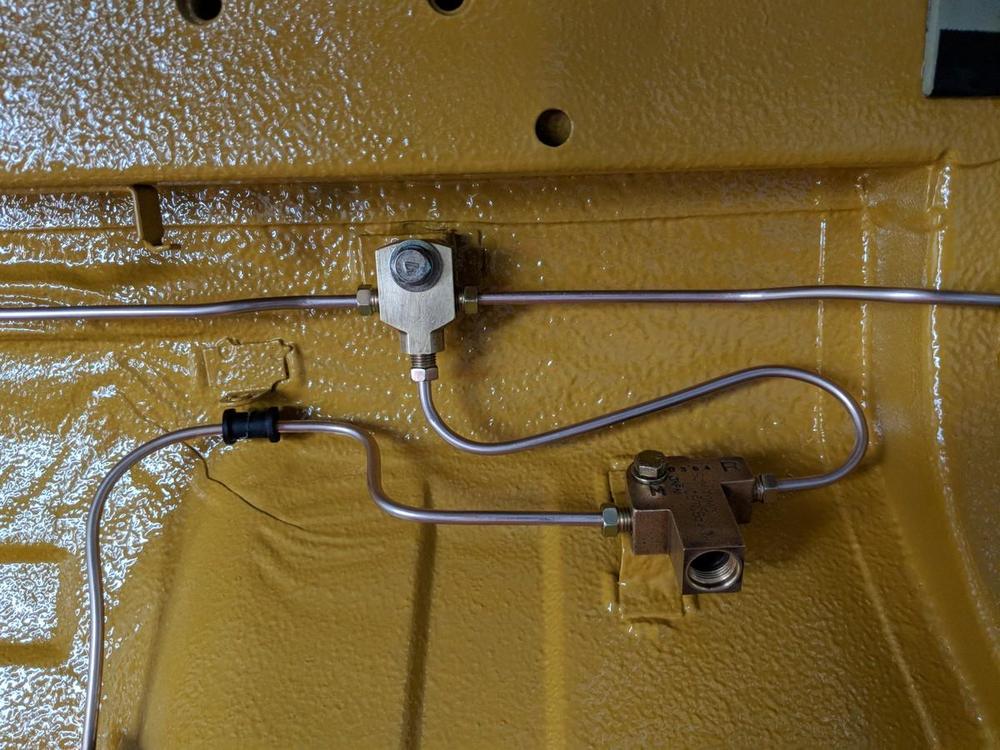

In other news we're getting close to our big brake upgrade on the front, pads have arrived, fitting kit cleaned up, disks and brackets on their way. I'm just waiting for the brake calipers to be done by BiggRed and then we'll be looking to get them fitted up. More than likely a job for next week to take the pressure off assuming the clipers arrive before then...

Fortunately the car is all fueled up, polished and stowed away in the garage for the weekend waiting to go this year, no more water pump fixes at 11pm the day before please!

A little detail I've been meaning to do something about for a while now!

IMG-9845 by Mark Woodrow, on Flickr

IMG-9875 by Mark Woodrow, on Flickr

One Template

IMG-9818 by Mark Woodrow, on Flickr

Test Fit

IMG-9820 by Mark Woodrow, on Flickr

Transfer Across

IMG-9823 by Mark Woodrow, on Flickr

Cutting

IMG-9825 by Mark Woodrow, on Flickr

IMG-9830 by Mark Woodrow, on Flickr

IMG-9847 by Mark Woodrow, on Flickr

IMG-9848 by Mark Woodrow, on Flickr

IMG-9834 by Mark Woodrow, on Flickr

The business end! IMG-9858 by Mark Woodrow, on Flickr

IMG-9864 by Mark Woodrow, on Flickr

IMG-9884 by Mark Woodrow, on Flickr

IMG-9891 by Mark Woodrow, on Flickr

IMG-9901 by Mark Woodrow, on Flickr

IMG-9920 by Mark Woodrow, on Flickr

Subscriber

Subscriber 4Points2,732Posts

4Points2,732Posts