Topics Last 30 Days

Showing topics, images, events and files posted in for the last 28 days.

- Today

-

Salvageable?

That rubber glue may be the least of your problems! I've done a Z dash pad restoration, starting with something that had only 25% of the deterioration that yours has. Even at that, it was a time-consuming job. Not only does the pad surface need to be levelled (not easy to get right, given the multiple contours), it's also necessary to 'V' and then feather-edge all of the cracks so that the filler won't crack along the seams. I'll bet it would take you 20 man-hours of effort (or more) to level, edge-treat, fill, sand, and paint a dash pad like yours to a decent level of final finish. But before you even get started down that road, you'll need to convince yourself that what's left of your original pad has enough structural integrity to prevent the pieces from moving around independently when the cabin temperature goes up or down. With its many full-depth cracks, I don't think I would trust your badly broken-up dash pad to meet that requirement. As a litmus test, it would be interesting to know whether a professional dash restorer like Just Dashes would accept your dash for restoration. Maybe you should send a picture and ask them. IMO, your best path forward will be to either: 1) buy a used dash that offers a better starting point for a DIY restoration (as Siteunseen suggests), or; 2) buy one of the replacement dash pads that have recently become available. In the latter case, you unbolt the old pad from the underlying steel structure (known as the 'armature') and then bolt on the replacement pad. There are a couple of threads on this site that discuss these replacement pads. As a third, lowest-cost/effort alternative, you could just replace your old plastic dash cap with a new one.

-

Odd Bolts in Balance Tube

CO, I have to apologize on what I said about the barb fitting taken off the 260z balance tube. I went back and looked at the balance tube, the fitting I have with 27 tpi did not come from the balance tube, it was in the box of parts and I assumed that's where it came from. You are right, you know your stuff. As soon as I get the brake problem solved I'll get back to my mixture adjustment and vacuum leak. Jim

-

SN 00042 Restoration; The Older Twin

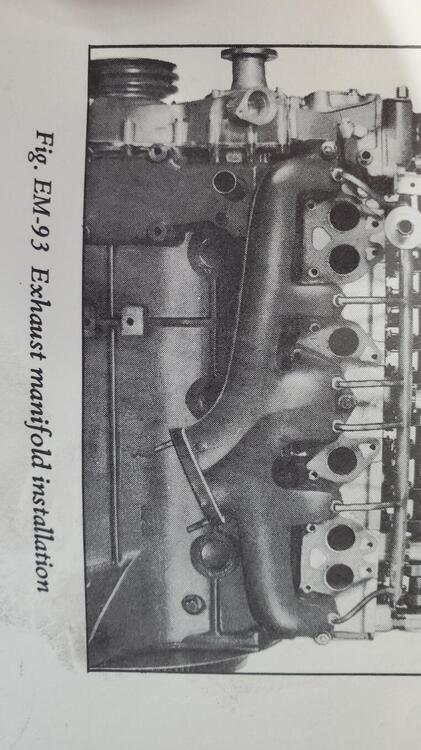

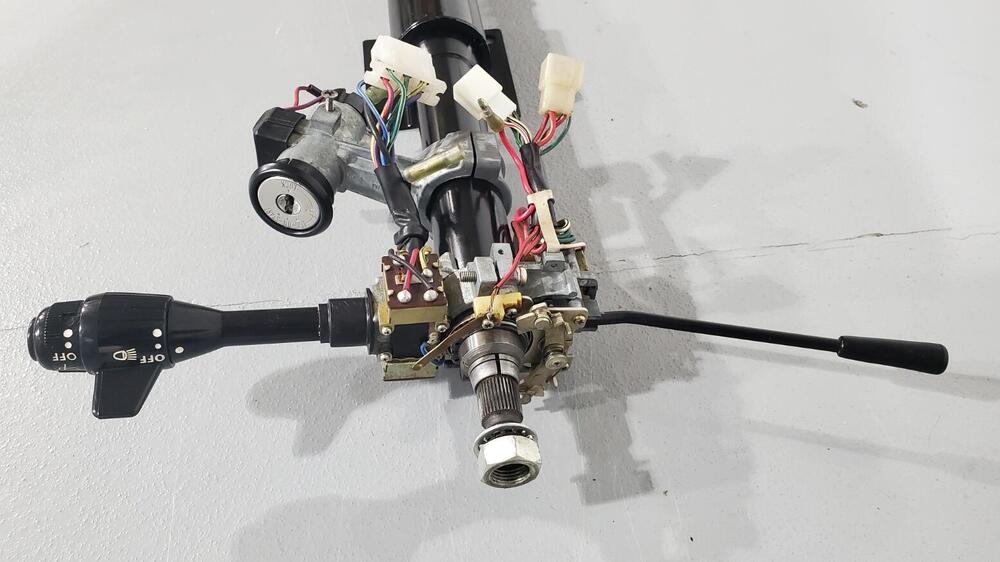

I should have a lot more updates and pics here as I have finished my summer home projects. Also, I am hoping the body and paint will be finished in the next month or two, so we should see some good progress. I appreciate all of the input here. I am always open to advice and the knowledge of those that have seen and worked on these cars in the past. Personally, I will listen to the panel of experts and then move forward with what seems to be the best direction. Also, as most of you know, I own a pretty much un-restored early 240Z that I grew up with since I was 9 years old (in the family for 55 years) , so I have a nice reference vehicle. That being said, I find it interesting that there seems to be a tendency to hold the ZCON judging in high regard. Personally, I do not have a very high regard for ZCON judges. In reality, many of them have never owned an original Z car or examined one closely. As a result, they make a number of mistakes in their judging, none of which can be contested because you do not receive the judging sheets until several months after the show. One of these days I will start a thread here titled "ZCON Judging Errors" and see who weighs in, in addition to the items I would list. A few examples are the deductions on my early Z for the weld lines on my oil pan. (FYI 0042 has the same weld lines so they will probably mark this off too). Another good example is the Franklin mint car losing points for having the 'Silver zinc' coil holder instead of 'Yellow zinc' holder. I have heard of judges insisting the original brake lines were stainless steel, the rear diff cover was bare aluminum and fuel hoses were not the 'cloth wrap' style. I am sure that I am just hitting a very small portion of the errors as I am only familiar with the cars that I have been involved with and what I can remember off the top of my head. Anyway, just had to rant a bit about the judging issue. Don't even get me started on the non-Z show judging. Regarding the Exhaust manifold finish, that is an interesting discussion. For most of my restorations, I have always consulted Les Cannady at Classic Datsun Motorsports and never questioned his advice (He was just 10 miles down the road) . If I am not mistaken, I think only his shop and Pierre Z were the only shops approved to build the Restoration Z's. Because of that, I have always used the gray powdercoat that he recommended as the default finish. However, given the current discussion and comments, sounds like there are several other options out there that might be more true to form. After looking at a number of different options and comments regarding the color, I am happy with the graphite finish option. Two of the items that lead me in that direction are pics from the Nissan engine service manual and pics of my own motor disassembly that are pictured below. Both pics show a dark cast iron finish, not a light gray finish. So, I am sticking with the graphite and will probably go with that in the future as well. I installed the exhaust manifold and intake assembly to the engine. Pics below. (Also looking for a correct rear engine hoist bracket) I finished up the steering column, and replaced the connector on the turn signal assembly. The main shaft was sanded and re-painted and all the electronics cleaned up. I re-finished the steering wheel that now looks much better, but not sure I will stick with this. The wood finish should be more redish. Problem is that the wood veneer is very thin and I am not sure how much was removed in the restoration attempt from the previous owner. Previously, the nubs on the opposite side were sanded through unfortunately. I will let it be for now, but may revisit it. The center metal portion looks good though. I cleaned up the brake and cluth pedal box. Ready for install. I have no idea what is written on that silver can below.

-

240z 4 speed manual

If it was mine I'd watch the play at the adjusting nut on the rod. Press the fork against the pressure plate fingers using one hand and run the nut in until you have contact with the fork with the other one. That would be zero play. Then back it off 1.5 turns. Easier to do the adjustment without the spring attached, since you'll be able to feel when you're on the pressure plate fingers. I've never done one but I think I understand what they're trying to accomplish. 2 mm of play between bearing and pressure plate when the slave clyinder is at the start of its stroke. Don't forget to check the pedal adjustment at the MC also. I've adjusted play there in the same way. Just max out the adjustment rod, being careful not to press the piston in to the MC bore, then back it off a bit. Another feel by finger job. And you don't need to remove the clevis you can turn the rod with a pair of pliers or a strong grip while everything is assembled.

- Yesterday

-

Let's show vintage racing pictures. I'll start.

-

Z's on BAT and other places collection

-

A Nissan (NISMO) DOHC Kit for the L Series is Officially Available

@Derek makes something similar. https://forums.hybridz.org/topic/119641-twin-cam-head-for-the-l6-from-derek-at-datsunworks/?do=findComment&comment=1249401

-

Parts for Sale: 280zx Turbo Hood Vent

Thank you, Buddy.

- Last week

-

Need a welder in Seattle

Hi Bob: If you are still looking for a welder I would recommend Elhot Metal Fabrication. He is working inhouse at the Shop club on 6th Ave S. He has done rust repair on 3 of my cars over the last 20 years and he is top notch. Of course with 30 years of experience, he's not cheap. Cheers, Mark G

-

The time has come for Zedyone to really look at brakes.

You are correct, I always has a very good pedal feel and then I did not. I think part of the issue is a bad check valve, and here is why I say that. I ran the check valve test with a vacuum gage installed down stream of the check valve in between the check valve and the brake booster. Warmed up the engine Let the vacuum gage settle down to about 45 mmHg or so (I think that was the number) Shut off the car and watched. The needle proceeded to drop and drop and drop and drop down to zero after about a minute or so. If memory serves last time I did this test, it held. So I ordered a new one. I will have to see if this helps or not. Either way, I suppose it is time to change it out as I installed that one back in 2009 according to my Z maintenance book I keep.

-

79 280z Brake Problem

Update. It's been several months when I posted questions about a soft feeling brake pedal in my 79 zx. I checked the vacuun check valve and found it to be defective. I didn't even use my vacuum test equipment but instead just removed it and blew and sucked through it and knew it wasn't holding vacuum. I replaced it and now have very good, stock brakes again.

-

Missing keys for a NOS ignition switch

Yes, take it a lock smith. If the core can be removed from the cylinder it isn't that difficult to make a key. Key blanks are common. I can't recall if the core is wafers or pins. Come to think of it, it's a double cut key, so it would be a wafer lock. To remove the core from the cylinder without a key, not a big deal to pick the lock. I have no idea what a lock smith would charge, but it's not a big deal. When I closed my business I kept all the key blanks, I probably have what you need. Jim

-

CAR STALLS WHILE DRIVING!!!

This was a clue that it was an electrical problem. If the engine was still spinning because it was in gear then spark will still move the tachometer needle.

-

Z Restoration Progam

I think you may find @26th-Z and @Carl Beck already have most if not all of the documents. I've hoovered them up for my archive. Will be interesting to see what if goes for this time, I think it sold at least once or maybe twice since the last BAT appearance 6 years ago.

-

Gas Tank Order From J30 in Netherlands

Any update. I suspect a gas tank from S30 World might be in my future along with Vapor Lines from Resurrected Classics.

-

1975 280z Build

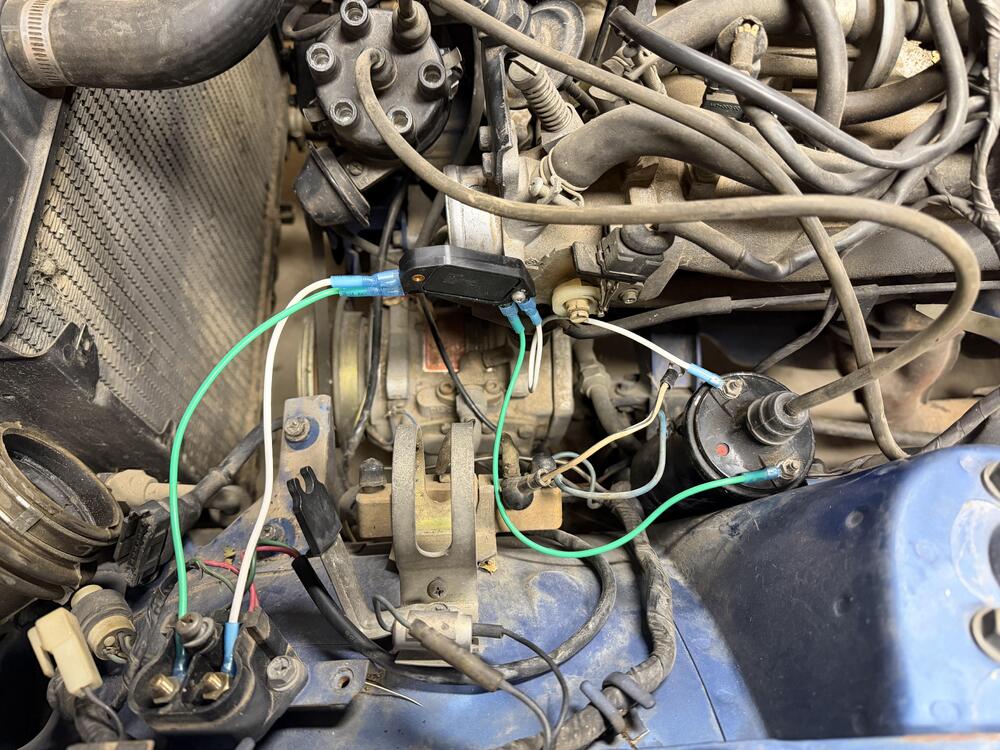

I pulled the computer out and took it apart. It looks really good, so I put it back together and started on the ignition module replacement. I followed this diagram that I got from the knowledge base and tried it out, but no joy. I didnt see anything about needing to run it through the ballast resistor, so I left it out of the new circuit. Im not sure which side is + on the coil so I put the new green wire where the old one was. I found another post that had a resistance measurement for the pickup coil. Looks like its suppose to be around 720ohms. Ill check that next time im out. Im sure im missing something, but im was too tired to really use my brain. The module is bolted to the throttle body temporarily. And I broke out my new plug wires as well. Anyone have any suggestions?

-

Dealer instaled AC unit 1971 Make offer

- For @yarb. This doesn’t concern you guys who aren’t in florida

- 280zx 1979 2+2 slick roof restauration

- R200 long nose 3.7 LSD SIDE YOKE ISSUE

All, Thanks for the info. Dropped the R200 in the car, your are correct, the driver side side axle is shorter than the passenger side. Installed the short axle in the CLSD, engaged flush and installed in the car. never run a clutch diff before. Are there better oils and weights to run in a CLSD? Spent the dollars on Red Line 75-90 w full syn for the open diff but not sure this is correct for the clutch unit? Any help would be welcome. Thanks again.- What does this do?

I plugged mine off but it doesn't get very cold down here. Less chances off leaking, losing coolant was my main reason. Lots of info in these threads... https://www.google.com/search?q=plugging+water+to+carbs+240z+classiczcars.com&sca_esv=77dc914585b7f4b2&rlz=1C1VDKB_enUS1121US1121&ei=1oETafjINaKHp84P-LudoAw&ved=0ahUKEwj4i8S_3uqQAxWiw8kDHfhdB8QQ4dUDCBM&oq=plugging+water+to+carbs+240z+classiczcars.com&gs_lp=Egxnd3Mtd2l6LXNlcnAiLXBsdWdnaW5nIHdhdGVyIHRvIGNhcmJzIDI0MHogY2xhc3NpY3pjYXJzLmNvbTIFEAAY7wUyCBAAGKIEGIkFMgUQABjvBTIIEAAYgAQYogQyBRAAGO8FSJZBUOkFWKcfcAF4AJABAJgBlgGgAcYIqgEDMC45uAEMyAEA-AEBmAIKoALsCMICDhAAGIAEGLADGIYDGIoFwgILEAAYsAMYogQYiQXCAggQABiwAxjvBcICCxAAGIAEGLADGKIEwgIKECEYoAEYwwQYCsICCBAhGKABGMMEmAMAiAYBkAYIkgcDMS45oAfSHLIHAzAuObgH5wjCBwUwLjguMsgHFA&sclient=gws-wiz-serp- 1970 drivers side A pillar section

About rust free section from a series 1 . Not using this so up for sale. Hard to find a clean section like this . I’ll ship anywhere 200$ Email Sfinnerty1018@gmail.com- And again, what does this do?

Thanks! Of course and now that I know I was able to find in shop manual.- Just Another Damned Z Car Project Thread

Well hell! @Tanker what year was that Honda electrical brake booster? Did you get a hold of the 3D print file? I’m intrigued but I can’t find the Facebook thread! 😫- S130/280zx Manual Interior Coolant Valve

@Terrapin Z - you have a PM! @kickstand80 - you have an email. - For @yarb. This doesn’t concern you guys who aren’t in florida

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.