Some weeks ago i got in contact again with Kris, the guy who bought a few parts from me, including my first, white S30 Chassis.

He's currently building a crazy Blow-through turbo S30 (more on that when it gets closer to completion) with all tricks and gimmics and a lot of custom fabrication, which includes a custom cast Turbo surge tank. For that reason he once bought some surge tanks from Japan to use as inspiration for his own design. Luckily he doesn't need them anymore, so they were up for sale. And even though i don't need them at all, who am i to turn down an offer on such cool and rare vintage tuning parts? So i went to their garage yesterday and picked up all of this. What a score:

The lot includes a set of 80'ies blow-through surge tanks:

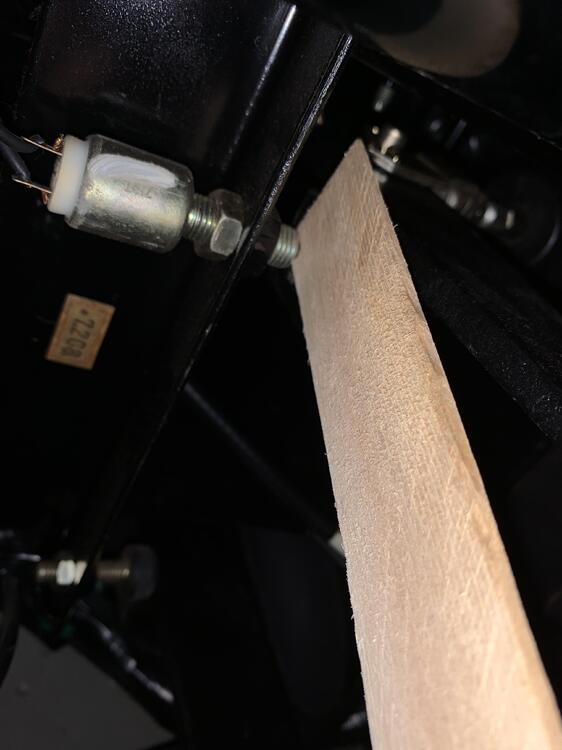

The first one is more commonly know. the SK compe turbo aka Sanyo-kiki Turbo surge tank:

This surge-tank acts as an intake manifold champer to the careburretors with an turbo attached to it. Yes, these where the very first and early turbo kit designs:

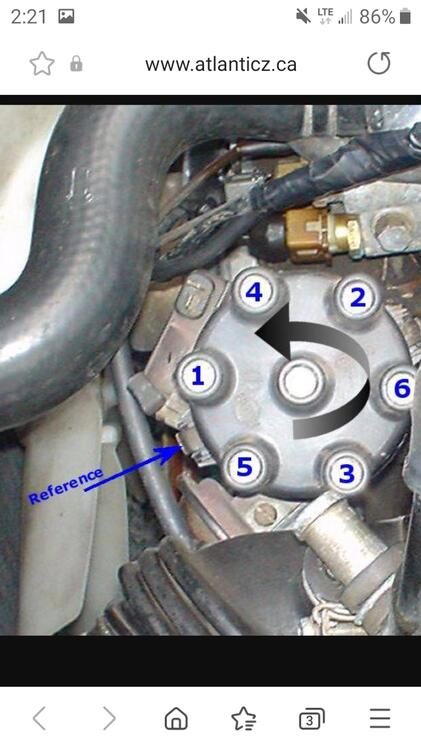

Ther second one, which i've never seen before is from the same era, but it's a JKC - Japan King charger surge tank, which was used together with a supercharger.

The design is very similar to other brands like HKS, but has those unique fins on it. The basic working principle is slighty different to. the one above uses a kind of "baffle plate" inside, while this one has a cast chamber inside.

Oh and he also had a huge bunch of Carboy and other vintage tuning magazines on hand, which he lend to me. There is a lot of advertizing and information on these turbo and supercharger kits in there. So i will try to complete my post about the different intake manifolds and turbo / supercharger surge tanks for the L6 engine with the latest informatino i got now. Thanks Kris for the Hospitality, and see you soon!

Subscriber

Subscriber 9Points11,142Posts

9Points11,142Posts