1. The fronts should be easier.

2.

Spindle pins in the rear can be a gotcha, should look up some threads on that, and look into getting a removal tool to assist with it.

if you use poly bushings on the tension control arm get a rubber bushing as a backing, sometimes they can be too stiff.

control arm bushings are asymmetrical (there's a recent thread on this)

inspect the control arms for cracking.

Paint stuff while you're down there.

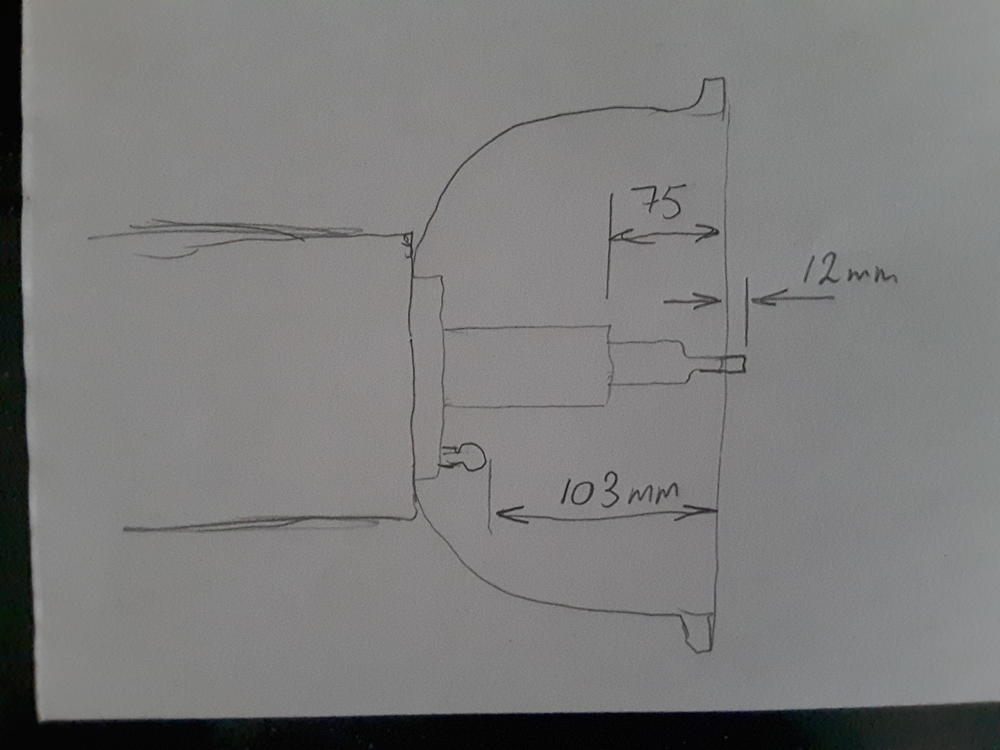

3. diff mounts would be nice, some use RT style mounts. I used the oem bushing, and the RT mount with a cone bushing to remove the OEM strap.

4. More vibrations from poly, although you cant find some of the OEM rubber bushings anymore..... I got the kit from Energy Suspension, you can find $20 dollar off coupons for AutoZone sometimes.

5. If your accountant lets you, i hear good things about the Koni Yellows. I use KYB struts, kinda wish i got the Koni yellows, i was a poor college student at the time. ha

6. I did not drop my subframe, i did one side at a time. I used a piece of wood to hold up the motor if i had it off the mounts.

7.

My bushings looked OK, i did not remove them.

I cant remember ?

I really like the RT mount https://technoversions.com/DiffMountHome.html I cut off 0.5" off the tip of the poly mount, i think @Diseazd recommended it but i could be wrong.

Subscriber

Subscriber 5Points3,770Posts

5Points3,770Posts