Today marks a bit of a milestone: the 240Z frame / Body / Shell is more or less completed.

The rollbar and all the accessories (optional passenger foot bar, etc.) are fitted.

And all the panels are installed:

The car got new floorpanes, new front inner fenders, rear quarters, rear inner and outer wheel wells, new frame rails, new inner and outer side steps, new roof, a complete new rear-end, new seat-rail mounts, and much more.

Many small areas like alle the little brackets got fixed and rectified. I think i can say the car is as rust-free as possible.

In the next few photos, you can find some details of how the rollcage was installed, as some were intersted how i installed it. I hope i got it right and close to the factory setup.

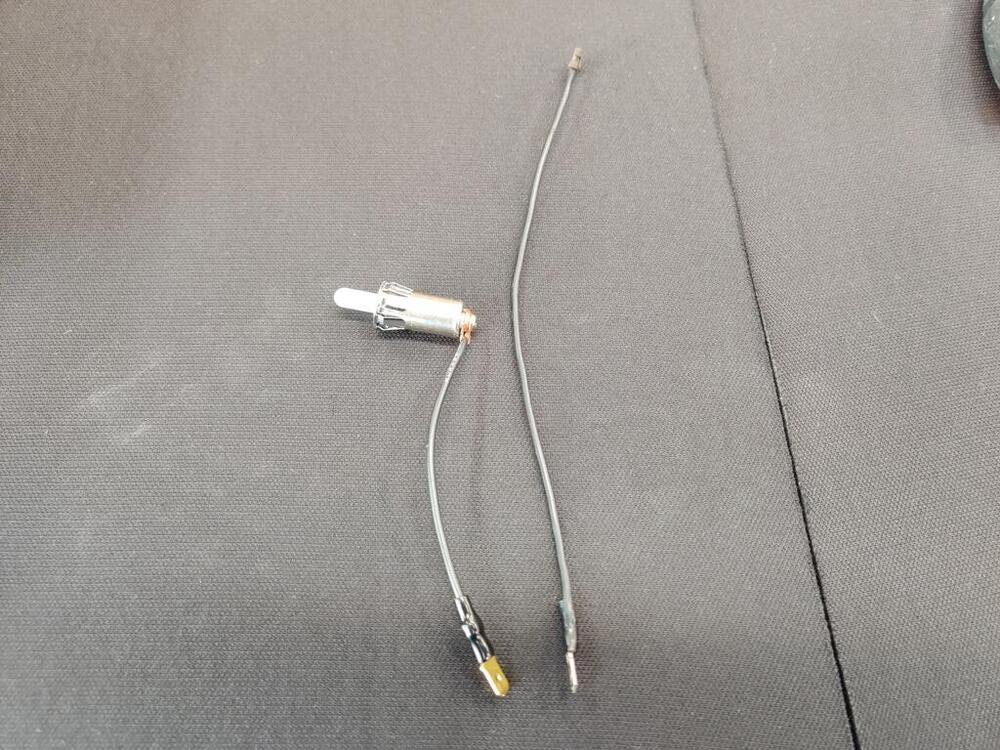

Welds from the bottom side:

Bolts from the other side (inside the inner rear wheel well):

So now? They'll deliver the car back to my own workshop, so i can install all the locks, spacers, rubber-dampers, trim, etc. before it goes back for final gap-adjustment and to get the sideline into the doors, etc.

Once the car is back in my place, i'll take a closer look at it and share the photos with you. On the first glimpse i'm very happy with their work. but there are still some areas to fine-tune and i'm sure we forgot some small things which i will figure out once the car is back in my place.

Meanwhile the next project is already waiting at their shop. A one of four known-to-still-exist Bentley Airline. Something in a slightly different category with wood frame and all.