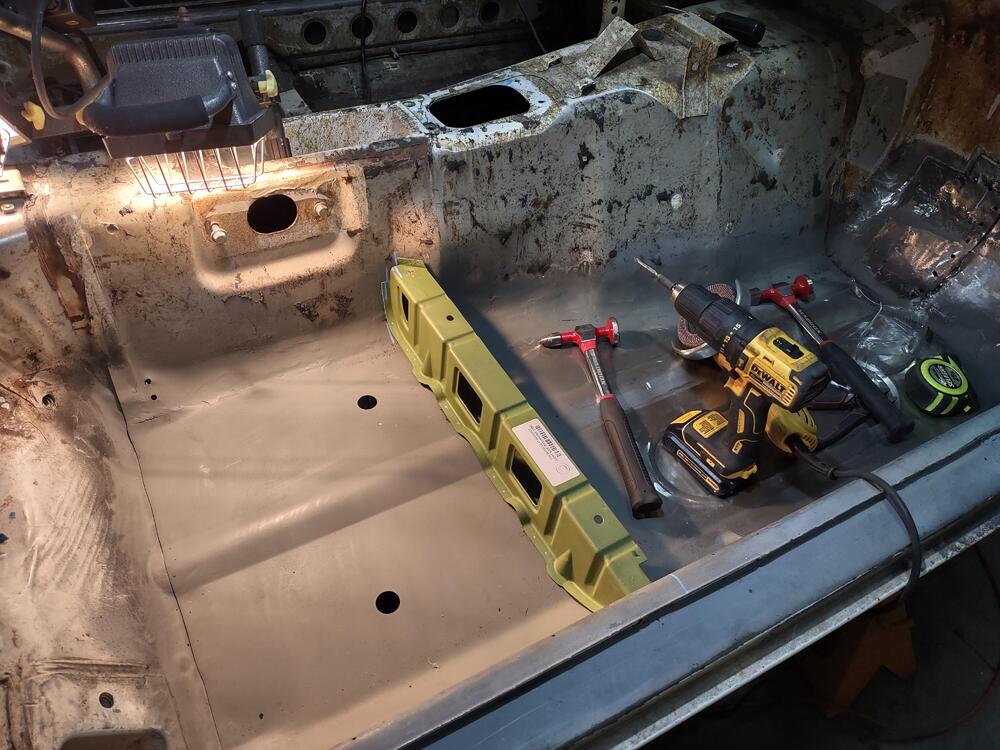

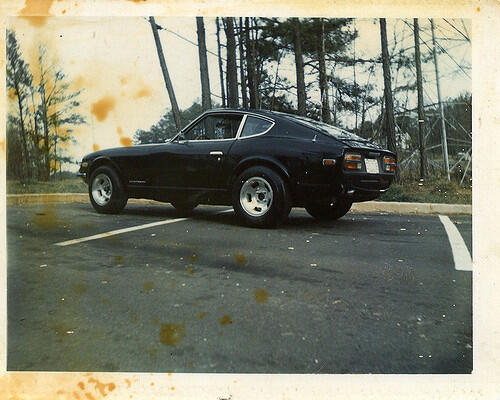

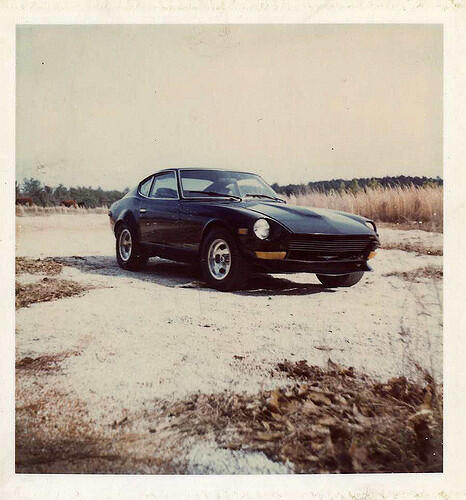

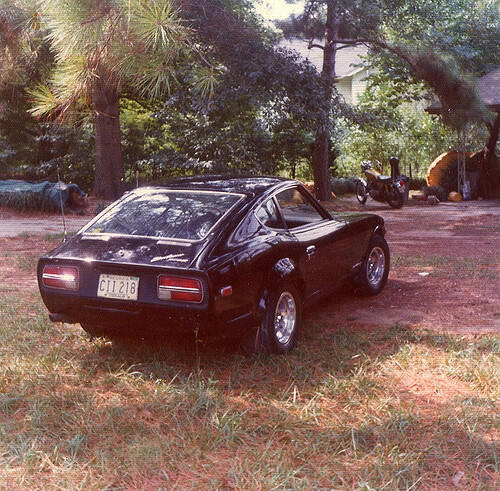

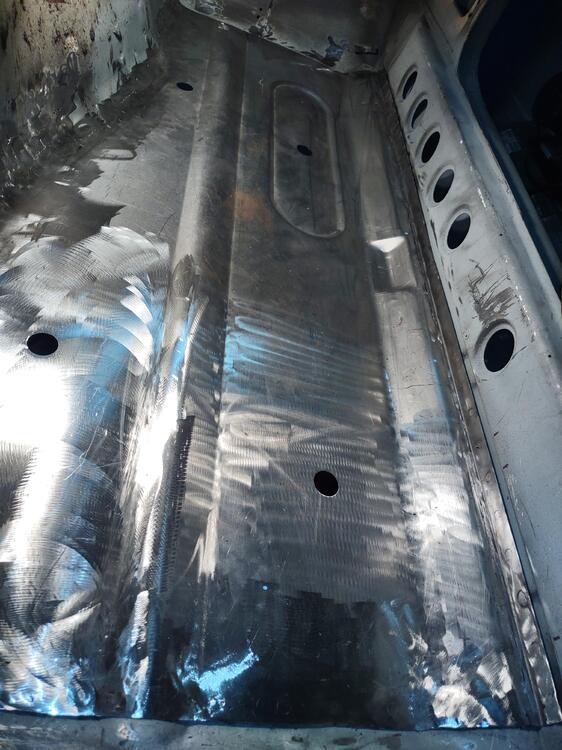

Here's an update on my Z, in case anyone's interested: To summarize, I chased a backfire/"frontfire" condition by replacing plugs, wires, distributor, timing chain, coil, points, ballast resistor intake exhaust manifold gaskets, head gasket, carbs. I brought the head into AutoSport (Seattle) for a valve job & had the head rebuilt and the intake & exhaust manifolds refreshed. I even painted the engine block while I was at it. The problem ended up being (drum roll...) 2 plug wires swapped at the rotor cap! Duh. (I give 99% of the blame to myself and 1% to the Haynes manual!)

Anyway, the engine looks and runs great now, and although I'm thoroughly embarrassed, I'm also extremely happy to have the Z on the road! Thanks to everyone who pitched in to help, and EXTRA SPECIAL THANKS to Steve @ Z Therapy. (What a great guy!)

Along the way I had a lot of fun and learned a ton. Now onto to the suspension...!

Subscriber

Subscriber 4Points11,142Posts

4Points11,142Posts