This week i sold these beautiful fenders for the s30 cars..

A set i bought from a Nissan dealer that stopped years ago. they are 240z fenders sold by black dragon.. and now.. they returned to the USA!!! Back to Florida after being in the Netherlands for years! 😂

Also sold with these fenders these sugarscoops or headlight scoops.

NOW FOR SALE:

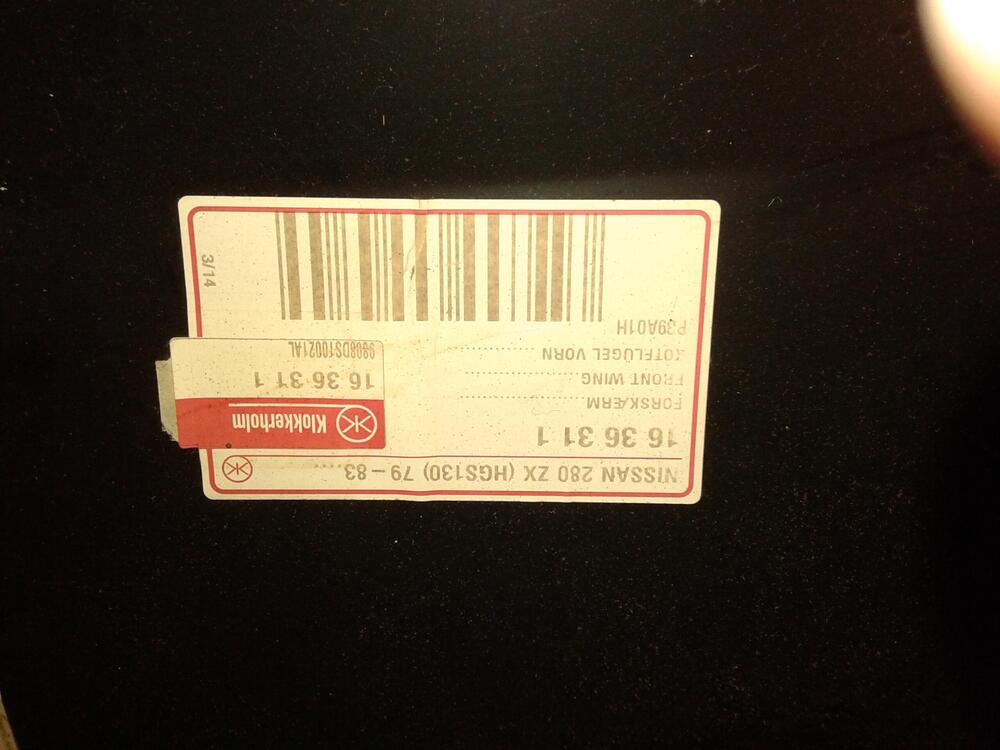

A new set of s130 (280zx(t) fenders made by (Swedish?/ German?) firm Klokkerholm (now? Würth?) ! These are in their original package. One has a little bit of undercoating but is in good condition. (You get A LOT of pictures of these fenders before i send them to you.)

LEFT

Right

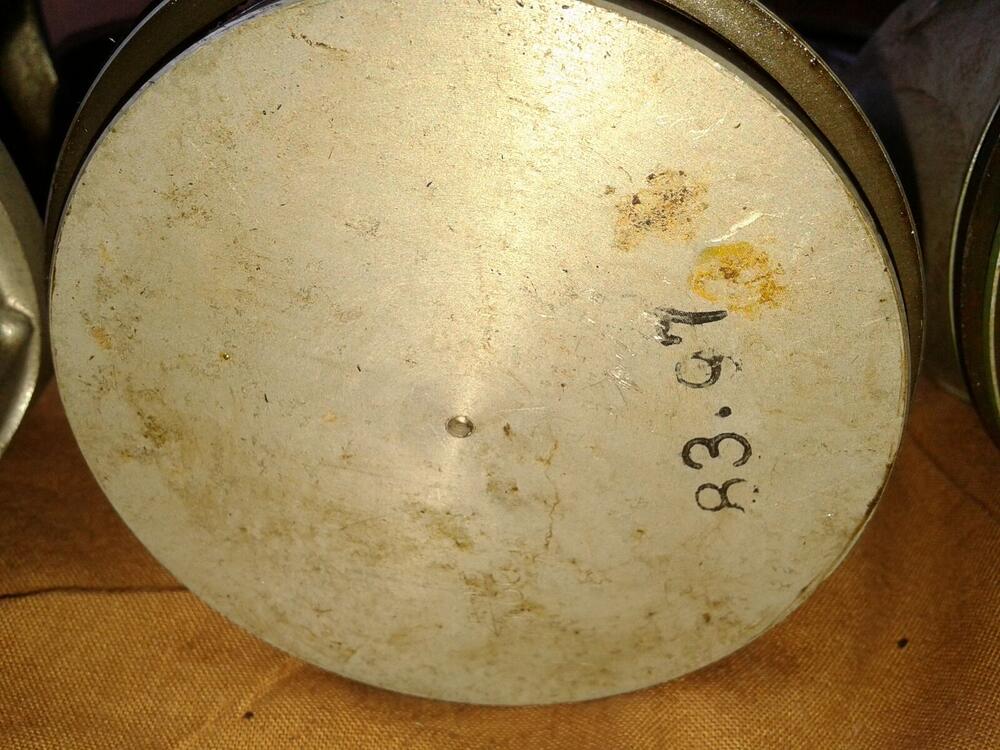

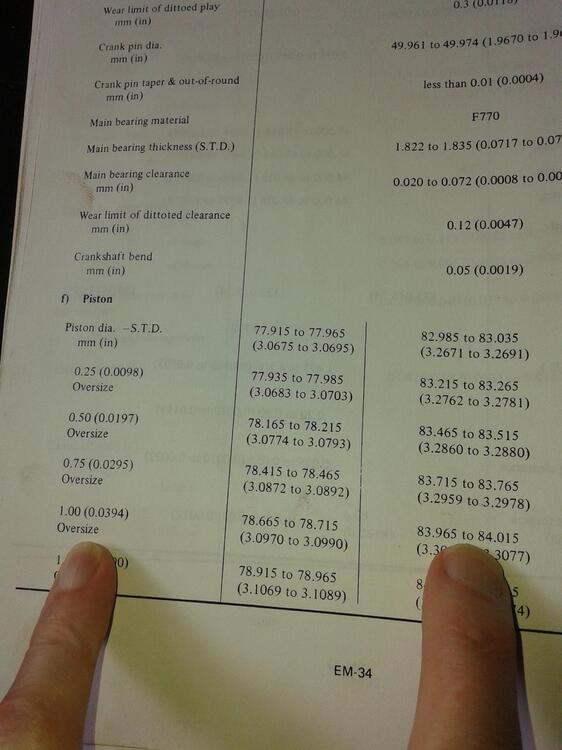

Then.. i have a set of oversized pistons.. ORIGINAL NISSAN OVERSIZE 1MM where are you going to find these !!!

6 x 83,97 mm (oversize) pistons for L24 Nissan 2,4 ltr. With connecting-rods complete. (New and also original Nissan.)

These are new and a bit greasy but new. 1 piston has another oil scraper but that should be no problem. (i bought these many years ago and it had the od ring on it.)

Top..

servicemanual says:

6 (or 7? i must ivestigate..) main bearing also available and many internal parts.. ask for your part.)

Finally i have a complete car for sale, it has been my summer car for 15 years! A complete history with a listing from the Dutch RDW which says this car has been in storage for winter at least from his 4-5 birthday!!! (that time before that it was at a dealers showroom!) So you can imagine that this car is imaculate on the underside as it is on top!)

It has it's original exhaust still after 29 years (1992) it's 3th set of tires (i had to put new on few years ago because they were so hard, car was sliding at every corner haha..)

Everything works but the headlightwashers.. (never bothered to look at it, i think it's bull**** anyway.. this car was never that dirty..)

The aircon works still perfect after 29,5 years!! Never been reloaded or something.. the secret? USE IT EVERY MONTH ONES! That way the lines stay greasy inside and you never get a leak .. it seems... last time i checked with a meter it blew 4,9 degrees celcius into the car and the outside temp was around 28 celcius!

A clean car without problems and a ful historie and with some beautiful car folders..

EDIT: forget to say the important thing.. it has 87600 Km's on the clock (54400 mls!) and as in the Netherlands we have for many years now NAP this means the milage in this case the km's are registrated with every year from the garage they have to put this on papers of the RDW when the cars comes in for APK (MOT in england) at your garage. So the milage is guaranteed by the Dutch RDW! ( DMV it's called in de States i think?) come visit: www.rdw.nl and find out how we do car registration..

You can contact me at: martzedcars@outlook.com (but beware these car don't come sheap.. anymore..)

Subscriber

Subscriber 3Points11,185Posts

3Points11,185Posts Subscriber

Subscriber 2Points1,979Posts

2Points1,979Posts

.thumb.jpg.2c428eacc1dfc62fbff0a58b4f63074b.jpg)