Leaderboard

Popular Content

Showing content with the highest reputation on 07/29/2021 in all areas

-

Steering Wheel Refreshing

3 pointsA little of topic but I have tested a product called Revive to refresh the finish of an old steering wheel from my parts car. I was very impressed with the result and there is no greasy feel to the surface. This steering was very grey looking before I started, but I didn't take a picture at that state. I first cleaned the wheel with soap and water and after it was thoroughly dry I applied the product.3 points

-

Restoration of HLS30-12070

3 pointsBefore and after for the gas fill area on the Z. Everything replated with new rubber bits to finish it off.3 points

-

How can I unseize a wiper motor????

2 pointsDon't assume! Figure out how to direct wire it for testing2 points

-

Did Nick ever finish this car?

2 pointsI was surfing on my phone at the time and couldn't read the valve covers. Be careful, bad backs are no fun!!2 points

-

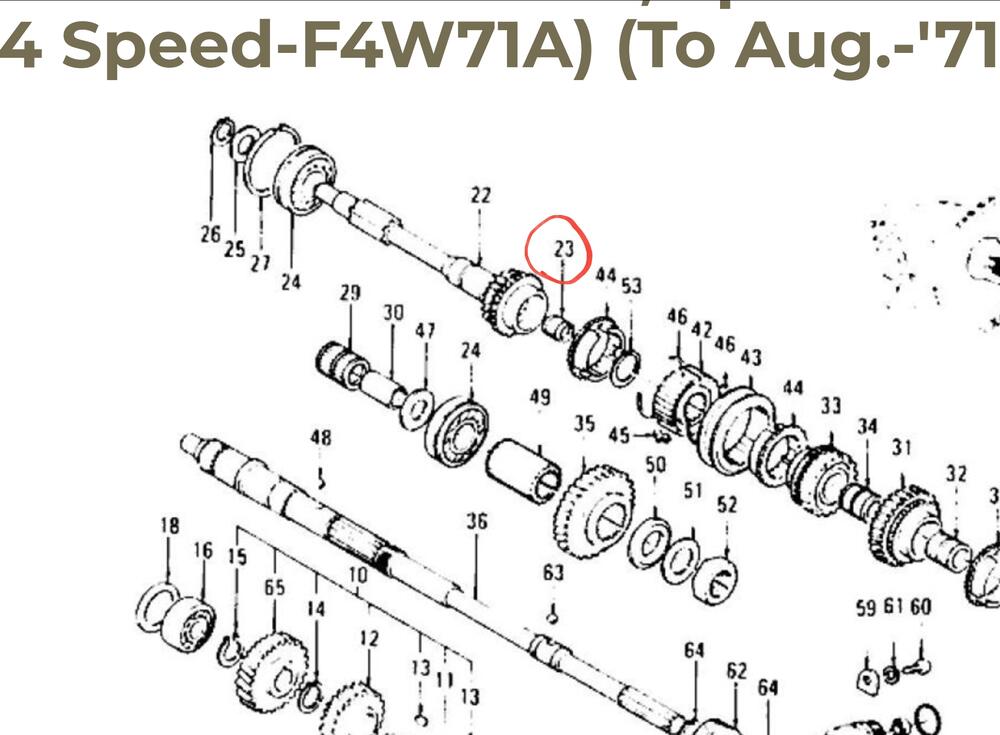

Transmission Noise in 3rd Gear - F4W71A

I now have read through this thread and what you are describing sounds like a failed neddle bearing between the input shaft and the main shaft. 3rd gear puts the most strain on that needle bearing. If it starts giving problems, then 3rd will show it first. It will be interesting to see what the bearing looks like.2 points

-

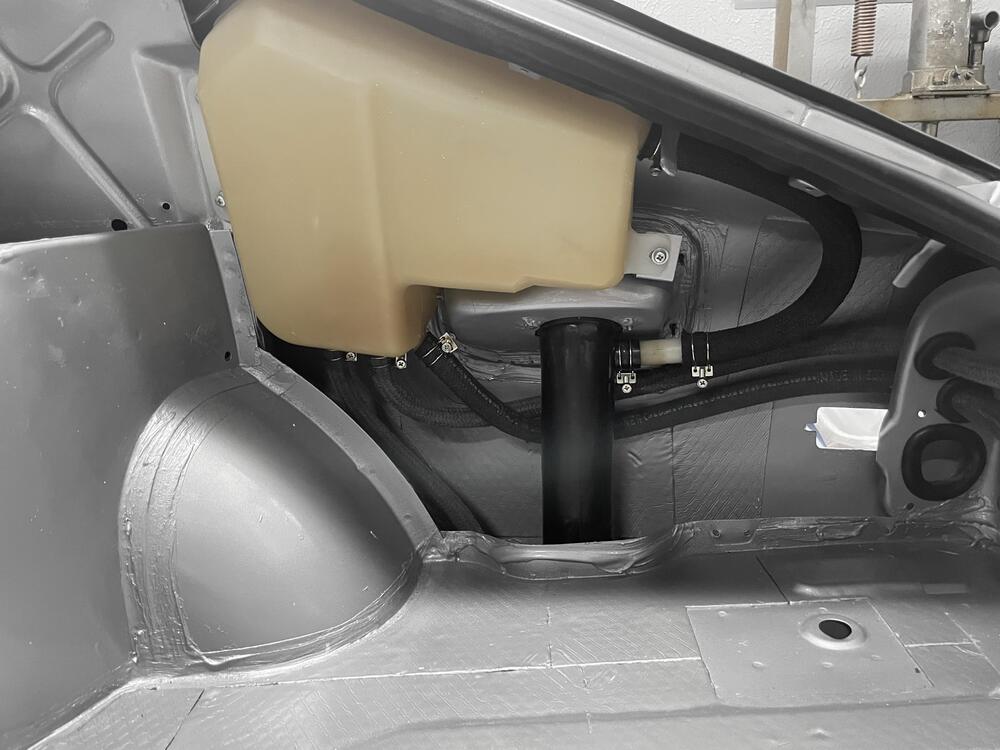

1970 HLS30-06521 Re-Restoration

2 pointsContinued with creating templates for the tar mat insulators. I have finished and uploaded templates for the rear deck area to our downloads in the cad files section, https://www.classiczcars.com/files/file/142-1970-240z-floor-tar-mat-templates/ Here is a picture of testing the templates to confirm fit. All that is left to do is the transmission tunnel area, hopefully I will get that done soon, before the shell goes to the body shop.2 points

-

Restoration of HLS30-12070

2 points

-

Did Nick ever finish this car?

2 pointsIt’s actually a 3.2L Maserati V8 & 6 Spd tranny. I’m in Australia. Thanx but have to be careful not to stuff my back so will be slow.2 points

-

Restoration of HLS30-12070

2 pointsFew more updates on the Z. Worked on rebuilding the quarter windows, finished up the vapor canister install, and got the antenna/speaker bracket in. Next I’ll get the wiring harness routed and have the hatch area just about done.2 points

-

Steering Wheel Refreshing

2 pointsHere's a couple of close-up pics of my wheel in process some years ago, one with it stripped and one with it stained and topped with a coat of clear lacquer. The preferred clear coat today is usually spray polyurethane. I used a hand-rubbed oil base stain.2 points

-

Transmission Noise in 3rd Gear - F4W71A

Hi AnvilZ, The movement you show in the video is not a problem. It is normal for the input shaft to move back and forth like that once it is removed from the transmission case. The input shaft is actually held in position by a outer circlip on the bearing. You removed the circlip to dismantle the transmission. The main (output) shaft should not move like that. If it does, then your centre bearing in the adapter plate has collapsed. The bearing kit for the FS5W71B will not work on the F4W71A. Different bearings. I have the bearing numbers somewhere, but it has been 7 or 8 years ago since I last needed them. I will see if I can find them for you. You can also dismantle the transmission and take the bearings to a local bearing supplier. They are common bearings.1 point

-

How Do You Properly Run An Oil Catch Can?

I used Toyota black FIPG(form in place gasket) on mine. It's holding fine after 1,000 miles at least, and the PCV system seems to be functioning fine. I'll bet that if I went and pulled on it with a bit of force it would break the seal though.1 point

-

Z31 N/A RB project

1 pointThis is just a remote base tune. It needs serious tuning STAT but at least it runs! https://youtu.be/xuvIezKbdXY1 point

-

How Do You Properly Run An Oil Catch Can?

Ok, here is my plan. It's a bit complex. Some pcv grommet from a multi pack, fits the stock check valve and block perfectly. I might end up moving this upstream, I am a little afraid of it getting oil trapped in it. Then BSPT adapter to hose barb. Hose barb to a true air filtering catch can. Catch can will be a billet version of the mann provent 100 or 150. Filter media gets 93% of particles prior to hitting my intake. I plan to change the filter every 1-2 oil changes. It will mount to existing 240z holes on the fender. Then from the filtering catch can, to the intake. This is all just for the lower block PCV. I haven't decided what to do about the valve cover one.1 point

-

How Do You Properly Run An Oil Catch Can?

I've run into the same thing and I was planning to use the green loctite sleeve retainer. Haven't tried it yet, but I have high hopes for that. And I agree that it's weird that the original pipe was in there so firmly, but pretty much shows no retention at all when pushed back in once it was pulled out. As for the PCV and catch can thing... With the EFI, things get a little more complicated. You need to either vent everything upstream of the AFM, or vent everything downstream of the AFM. But don't mix the two. Or vent everything completely separate from the EFI system. In theory, PCV systems change direction depending on the engine RPM and load. So the whole notion of "inlet" and "outlet" is a little troubling for me. At low load (low blow-by), high intake manifold conditions, the flow goes one way. But at high load conditions when the blow-by is higher and the intake manifold vacuum is pretty much non-existent, theory says that the flow direction reverses. I guess the "normal" direction is pulled out the large pipe in the crankcase, through the PCV valve, and into the intake manifold. So if I had an "inlet" and an "outlet", I would connect the inlet to the big pipe on the crankcase and the outlet to the valve cover.1 point

-

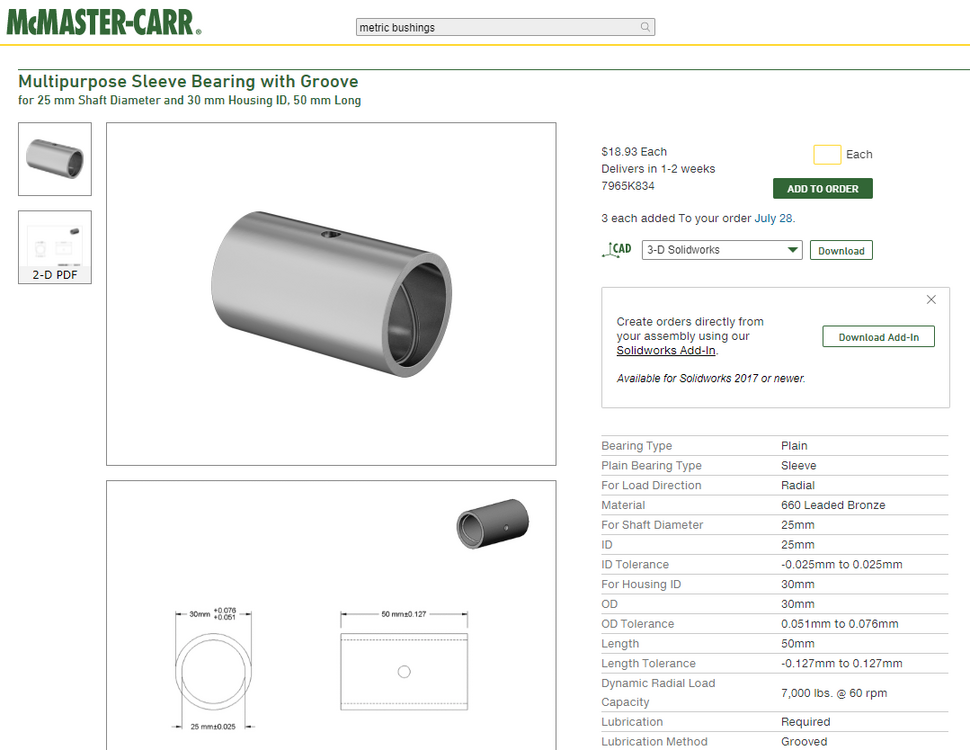

Steering Rack Disassembly and Refurb

My thoughts (for what they're worth): There are those that say machining the sintered oil impregnated stuff can be problematic. Unless you do it right, you can "smear" some of the material and close off the oil holes. That said, if you're only machining the OD, then that shouldn't matter. Also, SAE 841 is softer than the traditional "bearing bronze (932 or 660 leaded)". It's probably going to be softer than the original bushing, but for the steering rack application, it's probably good enough. As for the second choice from McMaster, I like that it's made from 932, and I like the oil groove. But if you cut 20mm off, you'll be cutting right through the middle of the oil groove. Now since we're using thixotropic grease and not oil... Does it really matter? And as you mentioned... I think a lot of this will all come down to how you like the fit on the ID. Good luck with the lathe work and keep us posted!!1 point

-

Did Nick ever finish this car?

1 point

-

How big balls

1 pointGentlepersons: I wonder if anyone can/will relate the actual size (in. and/or mm) of the distributor mech. advance bearing balls. My thanks for your considerations.1 point

-

How big balls

1 point

-

Getting the 73 Back on the Road

1 pointI finished the assembly of the Quickjacks today. Unfortunately, one of the air cylinders will not hold pressure. I even swapped the valves between the two ramps to see if it followed the valve. Nope. It was the cylinder. Bendpak has acknowledged the help ticket. While I wait for that to be resolved, the next round of parts arrives tomorrow, and I hope to get the screens for the banjo bolts on Friday. With car meets on Saturday and Sunday, I won't be spending as much time in the garage, but I hope to get a couple of more items crossed off the list.1 point

-

Can i use broken drivers side door handle on passenger side??

As I look back over this thread we should have asked you for a picture of the broken handle so we could have helped you better.1 point

-

Steering Rack Disassembly and Refurb

1 point

-

Intermitent start and no turn signals when it does not.

I took the hint from the turn signals not working. There are only a couple of common points between the start circuit and turn signals that would display intermittent failure. These common points are the battery terminals, the ignition switch, the ammeter, and the fusible link. The last two are not as likely to have intermittent failures. It's probably the switch on the back of the ignition switch. By the way @240z70, the turn signals not working could easily be the ignition switch. I do not make random suggestions often, especially about the s30 electrical system. Try operating the turn signals with the ignition off. If your car is wired as stock, they won't work. https://fiddlingwithzcars.wordpress.com/2013/01/20/hazard-switch-brake-light-turn-signal-circuit-analysis/ Now, here is how you can test what I said. When you have a hard time starting the car, leave the key in the ON position. Try turning on the fan. Likely it will not run. Also, the wipers probably won't work. The turn signals, fan, and wipers all get their power through the ignition switch.1 point

-

Transmission Noise in 3rd Gear - F4W71A

Sounds like something on/in the coupling sleeve and hub gears. Could be a chunk stuck in the teeth or a broken tooth. The shafts and main bearings are all shared between and the gears themselves are constantly meshed so a gear problem should be heard all the time. Only the coupling sleeve and hub meshes when you select a new gear. Although, there is a needle bearing under each gear that might deflect under load. Others have more transmission experience. Seems like you'll need to take it out and apart though to know for sure.1 point

-

15x7 Konig wheel tire thoughts?

1 point1 point

- Restoration of HLS30-12070

1 point- Technically, I bought another Zed....

Here is how I buy BMW Z4's I really like the color and the wheels. Most of the Z4's are silver, grey or black. Not many in other colors. It's an Si. I was watching a wrecked M roadster with 70k on it recently but just couldn't pull the trigger.1 point- Technically, I bought another Zed....

1 point- How Do You Properly Run An Oil Catch Can?

It's a press fit... once opened.... yeah your f***** 🙊0 points - Restoration of HLS30-12070

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber