-

Johnny280 started following Random Misfire while cruising , '78 280Z blows Hazard fuses - solved , '69 through '73 Steering Wheels - Wood, or Plastic? and 4 others

-

'78 280Z blows Hazard fuses - solved

Hello, just want to share my today's experience - maybe someone can benefit from it. I recently had a heat problem with my combo switch connector so I replaced it and also had a go at refurbishing my T/S and combo switch. Everything worked fine and I was able to use my headlights again (one day I will add some relays there). Some weeks later I noticed that the voltmeter was behaving strangely. It was jumping up and down and then suddenly stopped doing anything. I checked the wiring diagram and saw that the hazards are also involved in that circuit and that the hazard fuse was blown. So I put a new one in and it immediatelly went up in smoke. After ripping apart half of the interior I came to the conclusion that there is a short and that it is somewhere around the "key in lock" switch. A close look revealed that the switch came apart and the metal part that should be in the slot in the plastic part was shorting out against the shell. In my case the garnish ring sits so tight in the black metal bezel that when you try to remove it to get the plastic covers of you remove the garnish ring aswell. I remember that I did that when removing the T/S and Combo switches but never noticed that the contact was not in his slot.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

But Goertz still designed our car - yes?

-

280Z 5Speed transmission noise (with video)

First of all, thanks for your input. Unfortunately, there was no progress with the transmission yet due to some urgent problems with my daily car (1989 Mercedes 190D). The rear axle frame was rusted through + some 'minor' ventilation holes around the spare wheel well and rear wheel arches: Full rear axle restoration later + patching up ~5 holes I am now ready to get back to the transmission noise. @EuroDat Just saw that you are living around the corner. People are saying you are an expert in those transmissions. Maybe I can bribe you into a transmission-rebuild-weekend with some jerry cans of 'tax free' Aral Super Plus (Or other German 'Köstlichkeiten' of course)?

-

280Z 5Speed transmission noise (with video)

Yes, I read some of those threads. Especially, the one with the mostly missing bearing was impressive. I am just hoping that I can postpone the repair for a little while. I Don't want to miss out on the good weather days this year.

-

280Z 5Speed transmission noise (with video)

Thanks for the info. I guess it is time to start the planning phase - what is needed and how to get it to Europe.

-

280Z 5Speed transmission noise (with video)

isolated to the shifter. If I understand you correctly by pushing further into the gear the noise should get louder? In the video I tried to not move the stick but only touch it to better caught the sound on camera. I saw the process of replacing the o ring in some other thread and was amazed that one has to dismantle the whole afair to reach it. Is there a recommended bearing kit for these transmissions?

-

280Z 5Speed transmission noise (with video)

Good day, for some time I am trying to understand a transmission noise that is bothering me. As you can hear in the video the gearknob is transmitting some buzzing noise which can be altered by holding the hand in front of the knob to act like a kind of sound box. You can best hear it toward the end of the video. I read about the buzzing problem related to worn gearstick bushing and ordered a new set of oem bushings, cup and pin. After the change the noise persisted I also changed the old after market wood knob to an oem rubber one. Also no change. Next step was to check for wear marks on the stick (read it in some other post). I found some small ones, ground the stick a little bit so it wouldn't touch anymore but still no luck with the noise. As far as I can tell the transmission is a wide ratio FS5W71B (two ears at the extension housing). Oil is one year old Redline's MT-90. There was a little bit of 'metal dust' on the plug. I wouldn't call the noise a grinding noise. It is more 'fine grained' if you can call it like that, more like a buzzing. Like a very fine sandpaper on a piece of metal. It happens in all the gears and gets worse with speed. In the video i am driving between 75 and 70mph above that it gets even louder and becomes more like a hum. It would be awesome to hear your opinion on this one. Especially, if this is something to be concerned of or maybe even normal (don't have much experience with old transmissions). Three things came to my mind: 1. something related to the clutch/flywheel? 2. worn bearing in the transmission? 3. propeller shaft (u-joints, unbalanced)? I definetly have to drop the box in the future, because of some oil leak at the striking rod (leaks at the plug in the rear). So it would be nice to know if I should replace some parts to fix the noise in the process. Before someone asks - the butler creek flip up is covering some AFR display in case I don't want to see it.

-

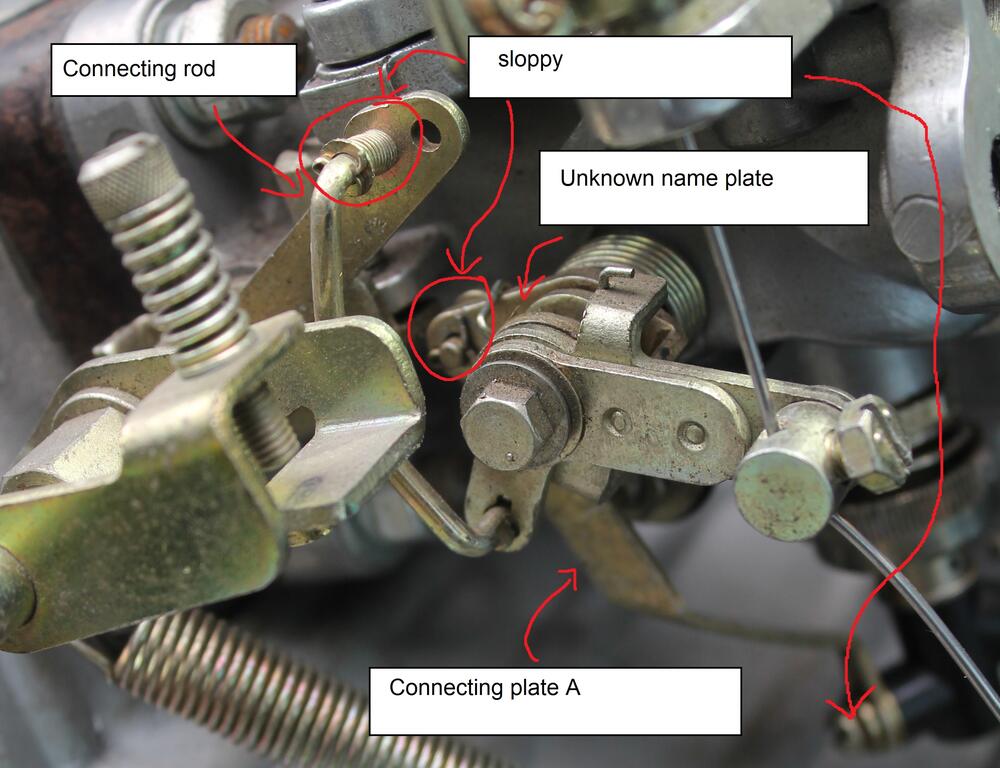

Play in Choke connecting plate 1 and connecting rod

Update: I removed the carbs and had a good look at the linkages. There were multiple things wrong: 1. the choke cable was indeed too tight and was preventing the spring to get rid of the play and keeping the nozzle completely up. 2. a wrong bend in connecting bar A resulted in the sticky nozzle situation. After some time I was able to bend it in a fashion that a) the nozzle stays up b) the nozzle is not sticky c) both nozzles move the same amount 3. had a look at the connection rod to the butterfly and bend it to match the specs in the service manual (between 0.59-0.69mm butterfly opening on max choke) Next step is to refit the carbs and get the choke cables on a little bit more loose then the last time. The original plan was to just swap the SM needles to SB needles to see if i can lean out the idle (had some filthy rich idle hot @10.5 while cruising @16+) a little bit while keeping a richer mixture at full throttle and cruise - lets see if that works out. Thanks again for the input and the reassurance that there was nothing wrong with the linkage.

-

Play in Choke connecting plate 1 and connecting rod

Thanks a lot for everyones input so far. A lot of stuff I have to think about. I will try to analyze the clamping situation first and fiddle around with all your different methods, then probably get the carbs out to check the linkage for canting. @siteunseen: The carbs are suppose to be ZTherapy rebuild ones and the rubber hose seems to be of the right type - flexible silicone ones. Regarding the Choke attachment. Yes, i replicated that one after wasting half a day building my own idea (wasn't aware that the internet had a pretty good solution). Mine was working but too bulky to fit under the console. One day I will place an order with ZTherapy and on top get one of those famed DVDs. @Captain Obvious: The flooding was pretty close to us but luckily we dodged that bullet. It was more to the south but a lot of the water was flowing down via the rhine which is only 300 meters away from our place. Waterlevels were not critical but unusually high for summer. Fortunately yesterday was only constant heavy rain (real German summer). I read somewhere that original SUs are first opening the butterfly and then enriching the mixture. Are our Hitachis the same in that regard?

-

Play in Choke connecting plate 1 and connecting rod

Hi, good to hear that sloppy is normal. First I will check the choke cables. Last time I worked in that area I was adding a floor mount for the choke lever and swapped the old cables with new piano wire (very smooth action now). I know that i brought the 'clamp lever' up to the point that i could feel the spring resistance starting to have immediate action when moving the choke lever. Should I leave some margin there? If that doesn't solve the problem I assume that the up and down play in Connecting plate A to the 'unknown plate' needs to be adjusted by bending Connection plate A in such a fashion that 1. the nozzle is not canted, to prevent any binding (current situation) and 2. in case of choke off keeping the nozzle completely up (in that position no up-and-down play should happen). Currently i would need to swim to the car. I will try to get fresh pictures of the return spring assemly as soon as possible.

-

Play in Choke connecting plate 1 and connecting rod

Hello, I was chasing down (again) a problem with a stuck open nozzle when easing out the choke on my SU carbs when I noticed some weird play between the Connecting plate A and the attached 'unknown name plate' on the choke shaft. Both carb have it - more pronounced on the front one. Also the connection between the connecting rod and the fast idle lever (the connection with the small spring) looks very loose. I added three videos to show the current situation. Any help and feedback is appreciated. If someone is wondering about the throttle return spring custom setup => i had to circumvent some fitting issues with the heatshield and Zstory headers. Also the dome screws are not tight on purpose. 1. Connecting Plate A This play results in the nozzle to not fully stay up when the choke is off. I wonder if this play is normal or if the linkage is worn out. I tried to decipher the parts manual (Carburetor L24 (To Aug.-'71)) and don't see any part missing (the 'unknown plate' seems to be 41 - PLATE "D" CONNECTING). The nozzle is able to roughly move 0.5mm. I can only assume that this is not ideal for fine tuning those carbs. If the play is normal would I need to adjust Connecting plate A to mitigate the up and down movement of the nozzle? Or do i need to somehow sleeve the pin on Connecting Plate A? There is also some play where the connection plate A is screwed into nozzle head (longitudinal). I added two videos, one showing the play on the rear carb and the movement of the nozzle on the front one (was unable to film both videos on one carb. But they behave very similar). 2. Connecting rod to fast idle lever My second concern is the slopiness between the connecting rod and the fast idle lever (the connection with the small spring). I added a video showing it on the rear carb.

-

Technically, I bought another Zed....

And will you go for tripple weber or stay SU?

-

$2.75 in N. Alabama

Can confirm from Duisburg - Germany. One Gallon of 'Super 95 (95 RON) today costs 6.77$ Don't ask for the premium juice. Edit: Of course those are our normal prices without any crisis 😂

-

Random Misfire while cruising

Hi, can you elaborate a little bit why you still want to remove the head to change the valve stem seals? The video I posted (pretty easy to find for everyone) shows exactly what needs to be done. I did it together with my girlfriend and it was pretty easy. You just need a valve spring compressor tool and some rope (and maybe a new valve cover gasket if yours is done).

-

Random Misfire while cruising

I used this video as a reference: worked like a charm for me (with the right tool).

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.