(Stating the obvious) A structure won't deflect unless it's subjected to a load. If the centre and rear sections of the unibody are supported (axle stands under the pinch welds at the front), then everything from the firewall forward will 'droop' because of its weight (i.e. load = force of gravity). However, there's not much weight left up front after you remove the engine/transmission, the hood and fenders, the bumper, the front suspension/steering and the front crossmember. As a start-off guess, I'd say maybe 150 lbs, tops.

In vertical bending, each side of the front part of the unibody gets its strength from a ~ vertical panel (the inner fender) that's reinforced by an upper and a lower boxed section. The upper box section is sometimes called the 'horn' and it's made from very thick (0.050" steel). The lower box section (aka the 'frame rail') is also made from 0.050" steel. The inner fender panel is the usual 0.032" (20 gauge). Both box sections are pretty deep vertically (which is what you want for vertical stiffness). The inner fender isn't really a 'vertical' panel, but it serves the purpose and it ties the upper and lower box sections together.

The center part of the unibody is boxed by the firewall (which is, in turn, helped out by the transmission mount frame that helps to reinforce the open trans tunnel area). The front frame rails aren't needed to box the center section of the unibody (as I think you would intuitively expect), so cutting one out isn't going to cause the centre section of the unibody to twist.

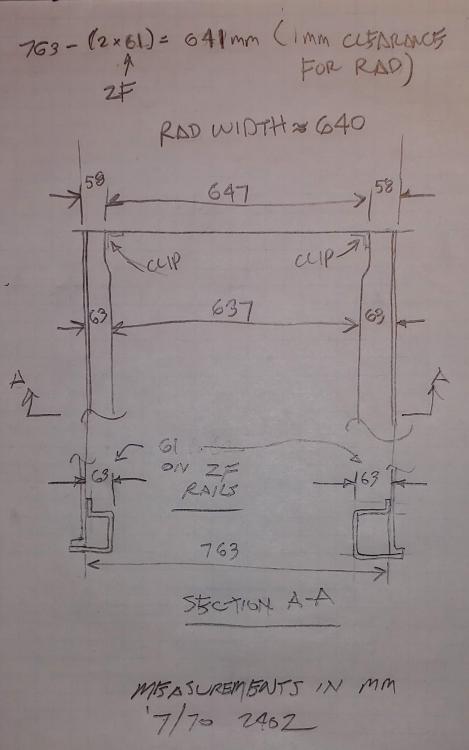

Ahead of the firewall, when you cut out the frame rail on one side you weaken that side of the front unibody structure somewhat, but the upper boxed section and the inner fender panel are still intact. I expect they're plenty strong (see next paragraph) to support their respective shares of the weight of the front section of the unibody (150 lb?) without any any droop, remembering too that the 'cantilever' effect of the structural weight steadily diminishes the closer you get to the firewall. The boxing of the front unibody structure at the front by the rad support frame will further serve to resist any differential droop (i.e. twist). Let's break it down...

I have one of ZeddFinding's replacement frame rails in my shop. It's made from 0.062" steel and weighs 8 lb. Let's say the upper frame rail weighs 10 lb. Then let's say the inner fender panel adds another 10 lb. Add 2 lb for the T/C Rod bracket. Add 5 lb for the shock tower blister. Add another 5 lb for the upper ledge panel. We're up to 40 lb per side, 80 lb total. Let's add another 15 lb for the front rad support bulkhead. That's 95 lb. Add another 5 lb for miscellaneous. Hard to make the whole front structure as being much over 100 lb. That's just 50 lb per side. And it's distributed over a length of about 4 feet (from firewall to front of structure), so it's not like a 50-lb point load hanging off each front bumper bracket.

When you cut out the lower frame rail on one side, the 50 lb on that side reduces by 10 lb. So 50 lb on the intact side, 40 lb on the cut side. 10 lb difference. Same as two 5-lb bags of sugar. Not much of a twisting load. If you're still worried, put an axle stand under the corner of the rad support bulkhead and shim it up to take out all the clearance.

If you're still feeling uncertain, put a dial indicator on the underside of the rad support on the cut side before you cut out the rail and measure the droop after the rail comes out. If you don't like what you see, use the axle stand and shims to push things back up into a zero-droop state before you weld in the new rail. If you do this, I'll be curious to learn what you measure. My guess is 4 or 5 thousandths of an inch (but I'm ready to be shown wrong). Maybe someone else has already made this measurement?

Everything I've said depends on your car having good structural integrity where the front unibody elements join the firewall (and, to a lesser extent, where the rad bulkhead joins the inner fenders).

You may find the attached article, 'Analysis of Early Z Chassis' informative. Credit to the author, James Lux. It appeared in an old edition of a unknown club publication called 'NewZletter'.

Analysis of Early Z Chassis - NewZletter - James Lux - 19xx.pdf