It is really past time for an update... 35 pics of body work follow - a lot of work to resize and upload and format ?. As always, clicking on the images gives you a large version.

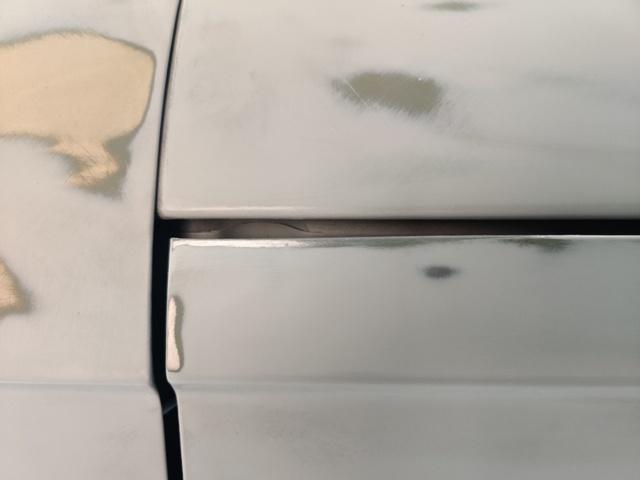

Passenger side door (upside down - front door gap to fender is the vertical gap) - cleaned of primer, and touch up weld to fill gap (center pic):

Fiberglass headlamp housings had not been primed yet - they were just sanded down. You can see the original primers that were used, first red, then dark grey. Following shows after guide coat and sanding of the two coats of high build primer. I broke through in lots of places. The panels were not nearly as straight as they needed to be.

I switched to a higher quality, fine body filler for the areas that needed it, like the passenger door:

Again, and I can't stress enough, if you want to spend less time and less aggravation on body work, spread your filler across large expanses of the panel (even the whole panel) instead of a little bit here and a little bit there like I always think I can get away with.

Left rear quarter panel, one of the straightest panels on the car, needed some filler in places at this "late" stage of the game. Imperfections of literally a thousandth of an inch can be seen when looking at a glossy panel. Using proper sanding technique is also very important to achieving a panel without waves.

3+ more coats of high build primer applied over the weekend. Places that I knew were not 100% right got an extra 1-2 coats, for a max of 5 in certain areas. I am hopeful that guide coat and sanding process will get me where I need to be, but I suspect that the car will still require another round of primer and sanding after this one is worked down.

Body lines are kept really sharp at this point in the game. They can be softened and made consistent later.

The body line above the rear fender appears to be a bit light to me, indicating the area is a touch low. We'll see how things take shape (or don't) as the next round of guide coat and sanding progresses in this area. Damaged rear edge of rear quarter panel looks much better now:

Door gaps (to fender, to quarter, to rocker, etc.) and alignments of all panels have to be done before you get to this high build primer stage. You can't be yanking and tweaking metal now.

I am letting the primer dry for a week so shrinkage can occur. I may leave it for two weeks, and then do the guide coat and sanding process. Plenty of other work that can be done in the meantime.