I have been rebuilding an R180 and have learned a few things.

Regarding backlash, I don't have to hold the pinion gear. All I do is fix the magnetic base and arms and dial gauge so that the motion of the rod on the gauge, when rocking the carrier, is vertical to a gear tooth. You don't want the dial gauge motion to be at an odd angle to the motion of the gear. Moving the rear carrier assembly by pushing on the gear teeth of the crown gear is easy, and the free play as the gear teeth smack into the pinion gear is very easy to measure.

So, you have none... that is odd.

Differential problems more often occur with the front bearings. That said, don't go taking everything apart to investigate. If it was me, I'd double check the lash measurement first. If still zero, than I think I would assume that the pinion gear has moved toward the crown gear, from some kind of change (damage) one of the bearings on the pinion gear. Pilot bearing would be the first from a probability standpoint. The front and rear pinion bearings are very beefy.

That said, I would not remove the pinion nut or disassemble anything relating to the pinion. I would remove the carrier from the case, and then spin the pinion gear to check for bearing noise. It should be quiet. If not, then I'd suspect the pilot bearing.

Very important - Troy Ermish recently told me that he never takes apart the pinion gear/bearings... ever. The reasoning is basically that it is exceedingly difficult to get the pinion gear set correctly when replacing the bearings. Part availability is a big reason for not messing with it.

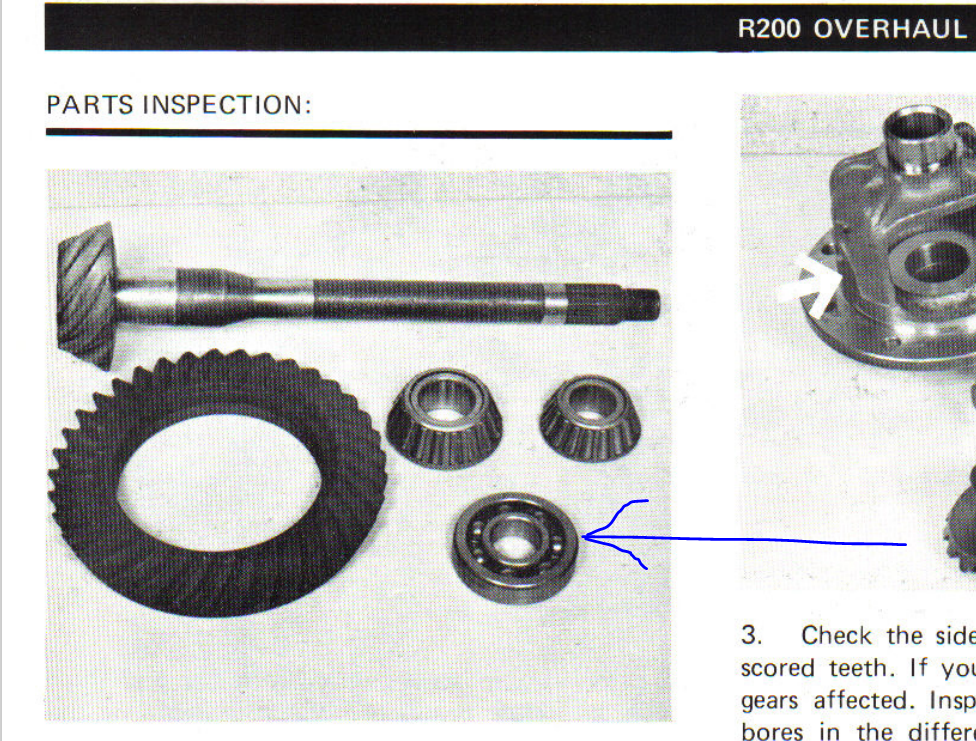

If it was me, and I confirmed noise was coming from a bearing on the pinion, I'd disassemble the pinion (hydraulic press work) and check the pilot bearing (after removal from the pinion gear and case. When you have just the bearing in your hand, you'll be able to confirm if it is bad. Before the next step, I'd put just the carrier back in the case, tighten everything down and check that there is some load (preload) on the bearings. Then spin the carrier by hand to check for noise from the side bearings. Depending on what you find there, side bearings can typically be replaced without additional issues/consequences.

Back to pinion. Remove the carrier from the case as you are done with testing that. Then, I'd put the pinion gear back in with the existing gears and spacers, etc. And I'd spin the pinion to check for bearing noise from the front and rear pinion bearings.

If they seem fine, then I'd invest in a new pilot bearing, install that, and follow the instructions VERY carefully for setting pinion bearing preload. When that is within spec, I'd install the rear carrier, and check back lash. Use all the stock shims everywhere they are - change nothing. If the lash is within spec, I'd proceed with checking the wipe pattern. That should look good if you don't replace the pinion bearings and use all the same shims/etc.

If that checks out, then install the diff in the car, put oil in and test drive. If you still have a problem, I'd recommend looking for another R200. Carriers, (your LSD unit) can be swapped to other differentials with relative ease.

Of course, if you have gotten to the point of needing another diff, then checking out the LSD thoroughly before you swap it is ground you should have already covered as well.

Subscriber

Subscriber 9Points11,142Posts

9Points11,142Posts Subscriber

Subscriber 7Points1,282Posts

7Points1,282Posts