The 25 mm ones are challenging to use for the differential front mount cross member if installing new control arm bushings. I couldn't get the bushings to compress enough by pushing the arm into them to get the 25 mm bolts to start threading properly. I'll be able to use the two 30's I've got to get it started. Once it is close enough, I will use two of the 25 mm for the other two holes. I'll probably swap out the longer ones after the cross member is in place and move those two to the transmission crossmember. Then, it looks like I will have the right fasteners in the right locations.

Working on the putting things on the car yesterday was very pleasurable. Not a lot of effort required, and was able to take my time and install parts that needed nothing other than taking them out of boxes and bags.

I cleaned and installed front wheel studs into the hubs. I believe the front face of the hub came from the factory with a machined surface. I elected not to remove the paint on that surface. If I had a lathe, I may have dress it and clear coated. Oh well.

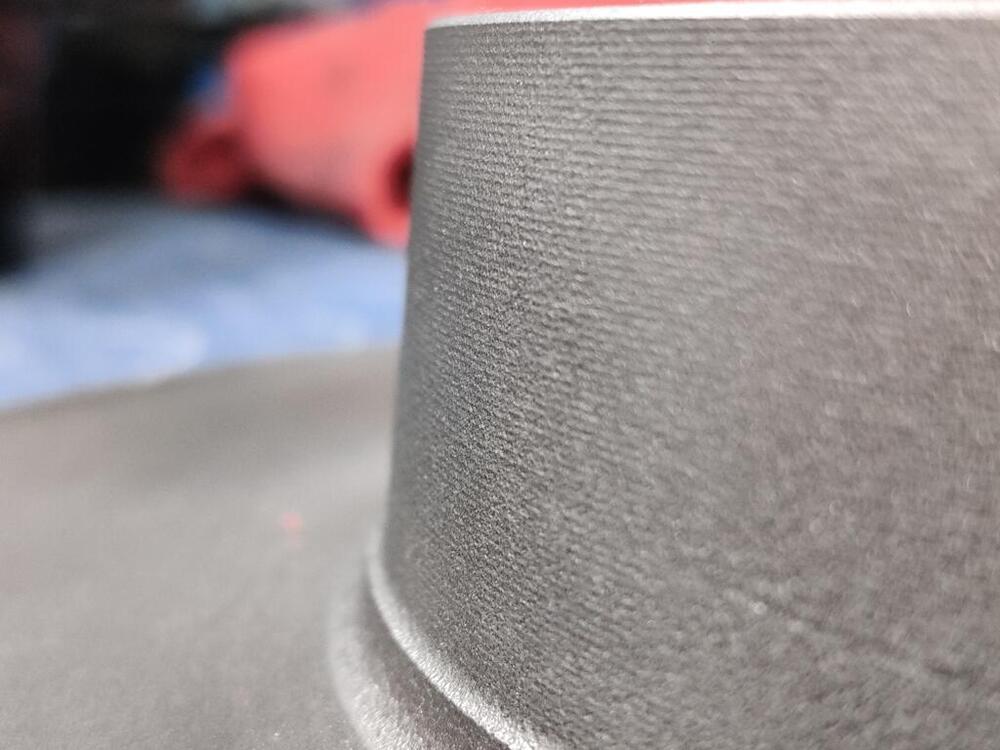

The brake discs that came with the car are interesting. I note that the hat part is tapered - in the picture I have the camera resting on the disc surface. You can see the side of the hat has an angle to it. The quality seems higher than many I have seen. I believe these may be OEM, but there are no markings which confirm.

I glass bead blasted the minor surface rust from the rotors and applied clear coat (spray can) to the front and back of the hat areas.

I worked a little more on the rear brakes, installing the left wheel cylinder (anyone know why both left and right hand brake levers have a big "R" on them?), hand brake brackets, and the small sections of rear brake hard lines. I also tossed one of the drums on and a wheel, just to have a look see. Still waiting on brake shoes to arrive.

I am also still waiting on the gland nut from Motorsport Auto. That is holding me up from putting together the front suspension.

Next, I moved to the steering rack installation:

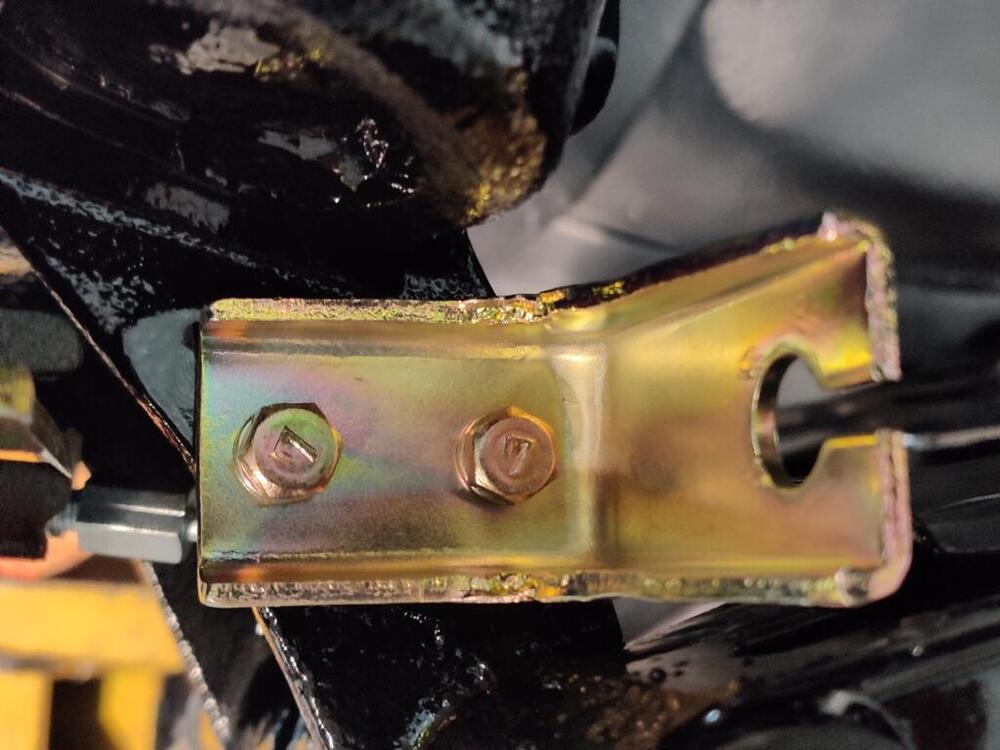

For whatever reason, the steering rack clamp brackets were semi-gloss instead of gloss. Original finish pics - anyone know the correct orientation of the paint dots? Front/back, left or right?

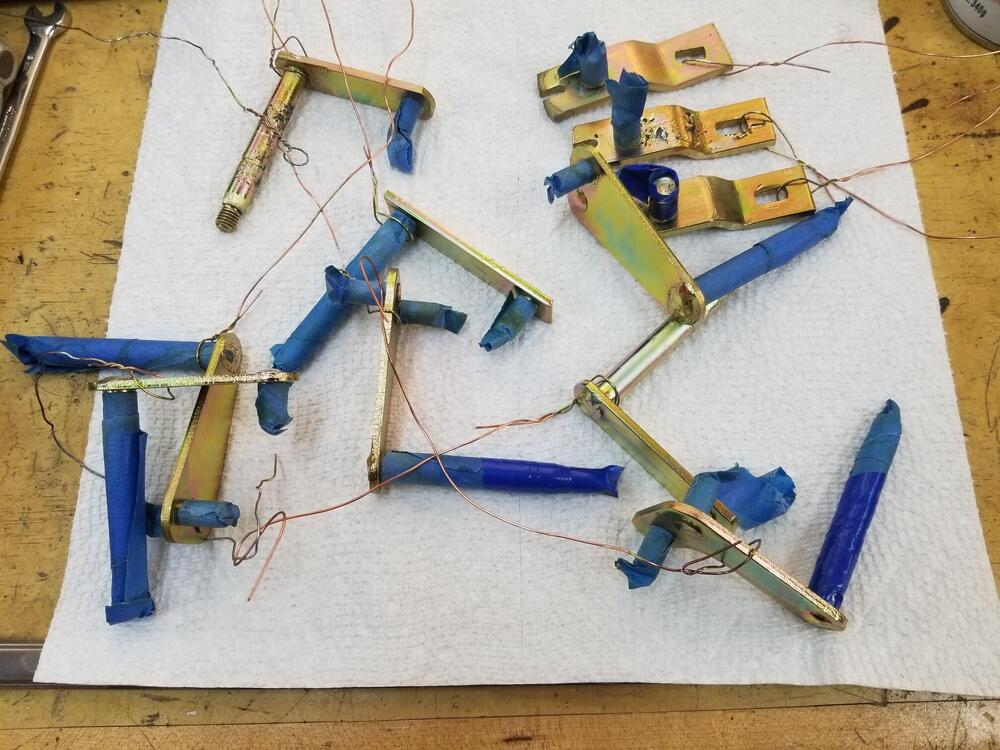

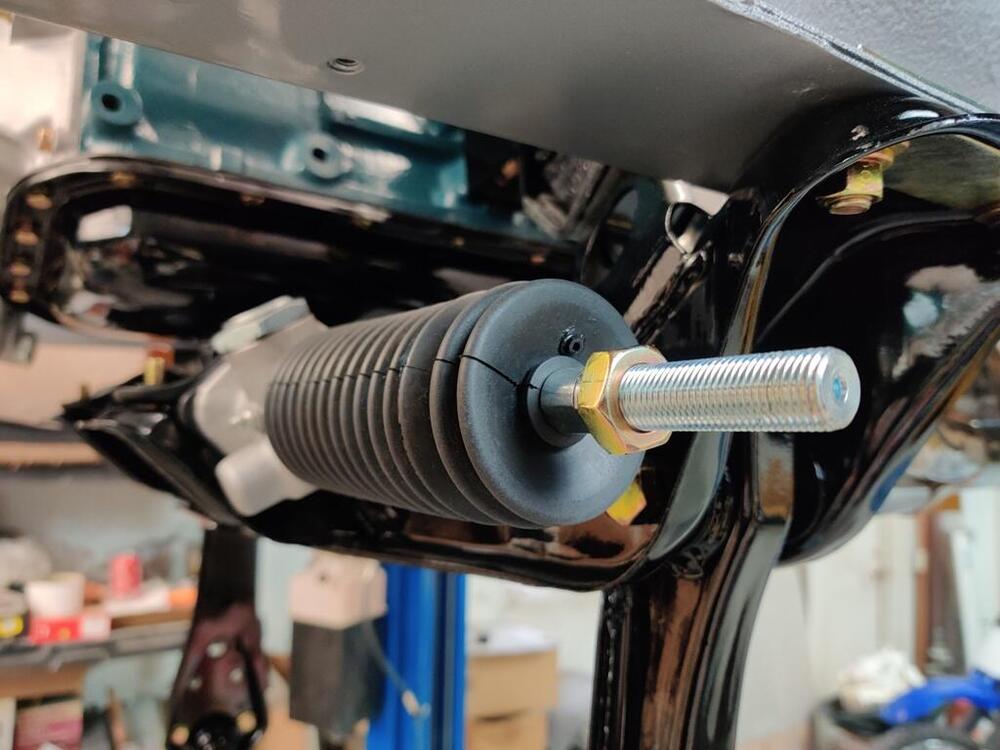

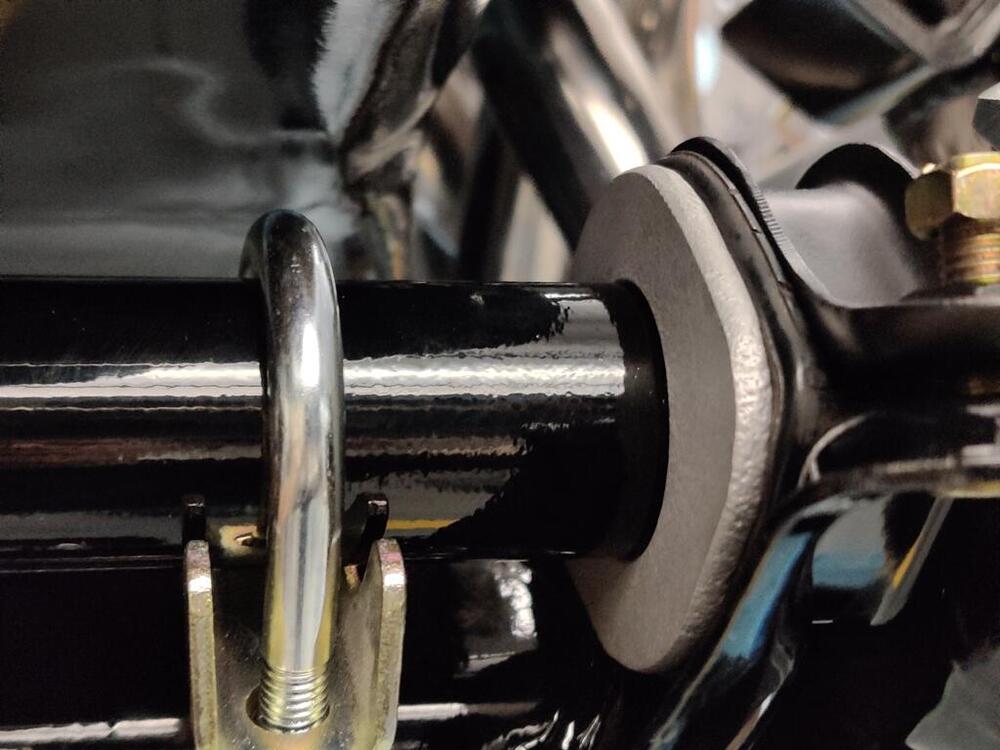

Steering rack brace. If you look closely at the U bolt, you will see that one side has more threads than the other. That longer side goes towards the front of the car. The brace is not clamped down yet in this third pic.

Don't think it matters, but used an old rack to determine the location of this brace.

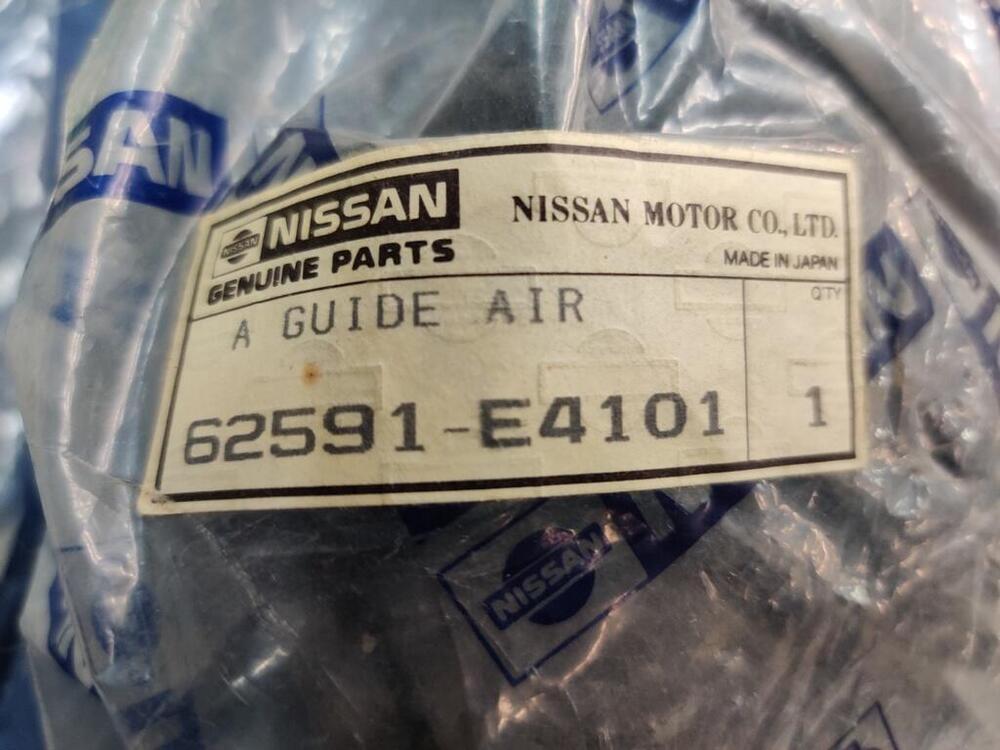

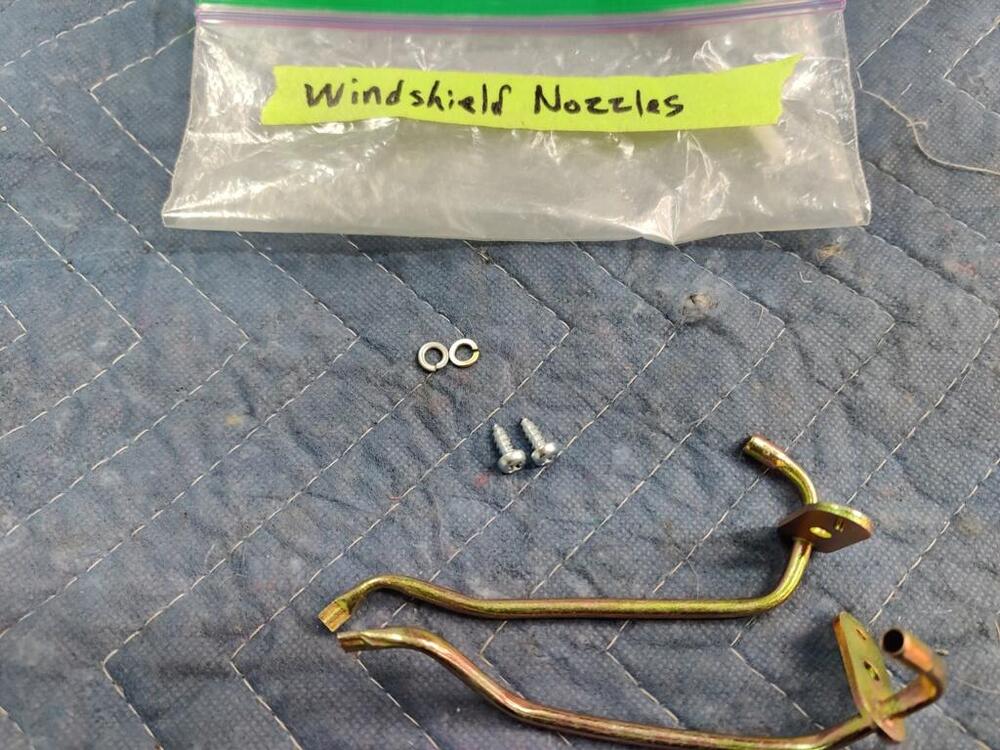

Today, I will be adding items to the engine compartment.

Subscriber

Subscriber 5Points11,142Posts

5Points11,142Posts