I cracked the code on the horns.

I was working on getting @Tirnipgreen's re-plated horns working. I tinkered with them some a while back, but I needed some time to focus on them to get the bugs out.

Fortunately I had one of my old 260Z horns that was unmolested to use as a template.

Before I go into detail, let's talk about the theory of operation.

When you press the horn button, the relay sends voltage to the horn.

The coil in the horn is energized, pulling the diaphragm in.

The bar on the back side of the diaphragm hits a tab on a set of contacts on the negative side of the coil, de-energizing the coil.

The diaphragm snaps back into place, allowing the contacts to close.

Repeat steps 2 through 4 as long at the horn button is depressed.

The vibration of the diaphragm is what makes the sound.

So what appear to be the potential failure points?

The tab for the positive wire on the outside of the horn loses electrical contact with the coil inside the horn.

The contacts get carboned up.

The bar on the diaphragm is not aligned properly.

The tone screw is not adjusted properly.

I don't have a documented fix for #1. You see it by measuring resistance between the outside tab and the inside of the horn where the coil wire is mounted. Ideally, you should have continuity.

For #2, test by measuring resistance from the positive side of the coil to the body of the horn. It should be less than 2 ohms. To lower resistance, I cut a 3/4 inch wide strip of 1000 grit sandpaper and folded it in half. I worked it between the contacts and pulled it through a couple of times, using the tab on the contacts to moderate the pressure. I measured resistance from the positive to body of the horn until it dropped to less than 2 ohms.

For #3, I took a straight edge and held it against the side of the bar. There are two alignment holes on the diaphragm, and I noted the distance between the straight edge and the hole. It's between 1 and 2 mm. If the bar on the horn you're working on doesn't line up that close, loosen the M6 nut and rotate the bar. Hold it in place carefully while locking now the nut.

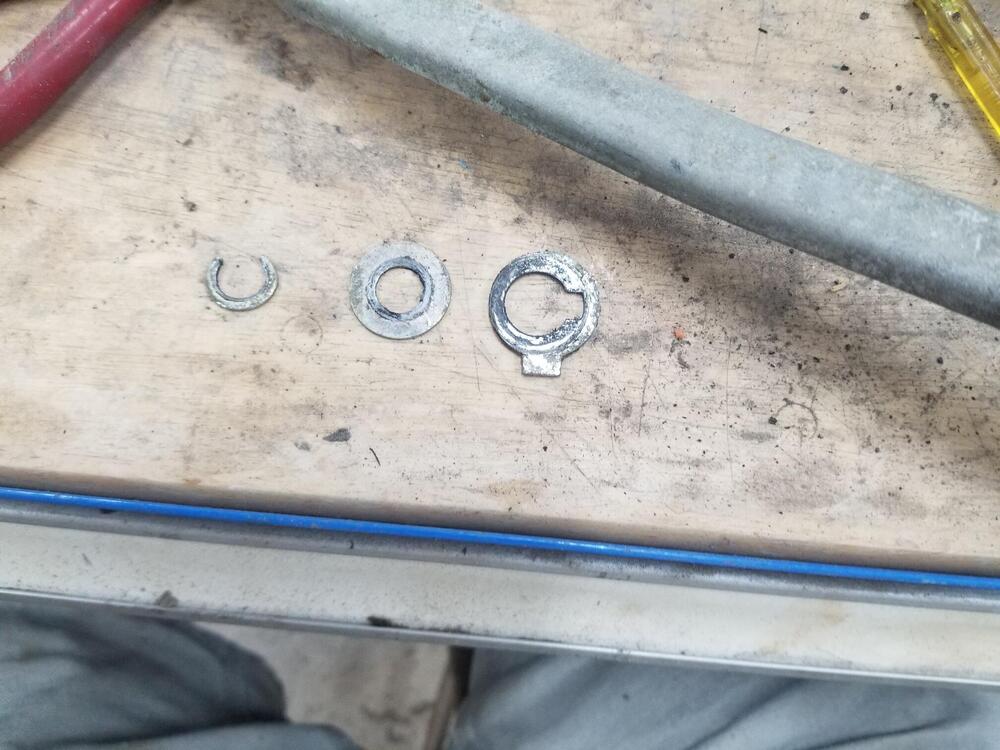

After adjusting the internals, put the horn back together. Measure resistance from the positive tab to the mounting bracket of the horn. If it's more than 20 Ohms, the tone screw is turned in too much. The tone screw is an M4 screw on the back of the horn. The screw in the photo below was powder coated onto the horn, and I had to break it loose. I got the resistance from being over 1 MOhm to around 2 ohms.

After that I used a car battery to test the horn and get a better tone. I had to work the screw in and out a few times until I was happy with the results.

20230910_153848.mp4

The other horn was a little more challenging. When I tried to break the screw loose, the screwdriver chewed up the head. I had to replace it with the only screws I had available, allen head screws.

After playing around with the height of the screw, I finally got a decent volume out of it.

20230910_160521.mp4

Subscriber

Subscriber 3Points11,142Posts

3Points11,142Posts