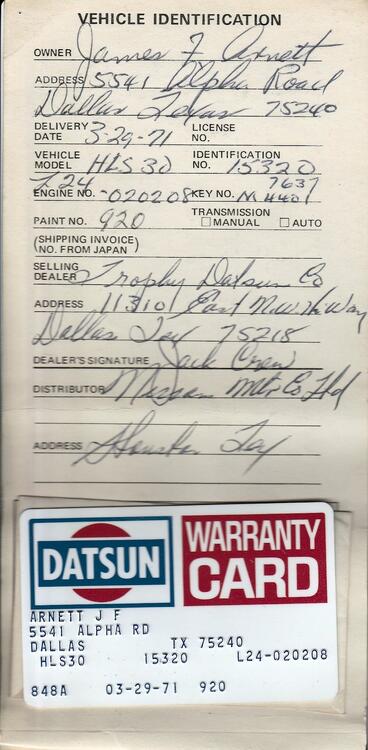

The EFI does depend on the coolant temperature sensor for correct fueling. As the coolant temp goes UP, the resistance DROPS. The FSM shows a table for expected temp vs. resistance values in the Engine Fuel section (page 53). Why would you want to ADD resistance to the signal using a variable resistor? Else, why would you remove the coolant temp sensor (thermistor) by replacing it with a manually controlled variable resistor? The aged wire and connectors in your engine harness may already be skewing signal with additional resistance. Additional resistance which would fool the ECU into thinking the engine was running cooler that it actually is.

I think a more productive route would be to measure the resistance at the sensor, and then at the ECU - to see how much additional resistance wiring and connectors might be adding. If the skew is significant, a new wire and connector from the sensor to the ECU might beneficial. In my years with this early EFI and ECCS in S30's and S130's, I've found 90% of the problems to be in wiring and connectors. I've always advised: Clean both sides of your connectors, then do it again, Ya... then do it again. and don't forget the ECU...

Most people ignore me and just go straight for the AFM. When you know everything there is to know about that Bosch L-Jetronic AFM, go ahead and bust it open. Trouble is, if you did know everything there is to know about that AFM, you'd never actually do that...

Subscriber

Subscriber 12Points11,142Posts

12Points11,142Posts