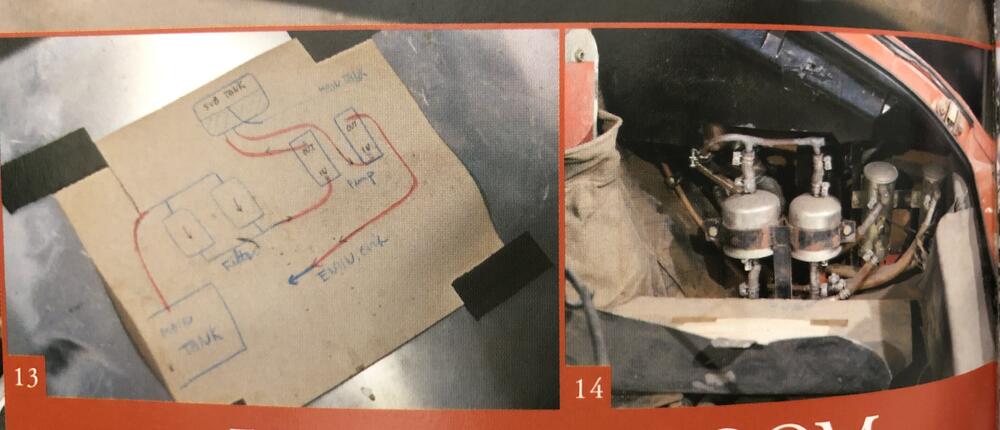

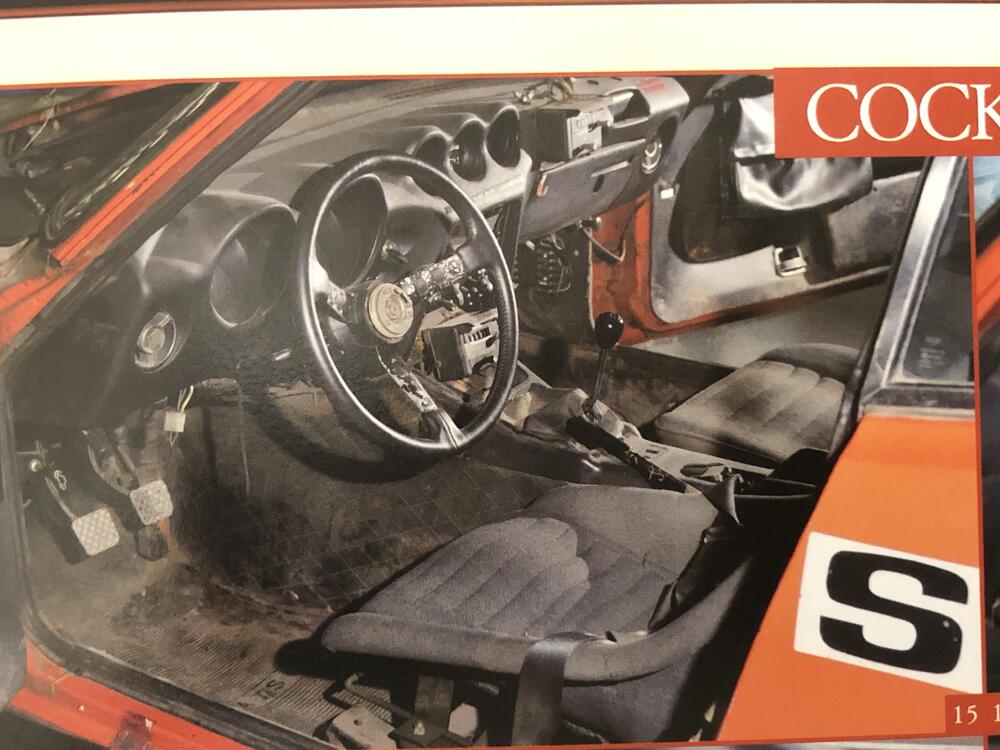

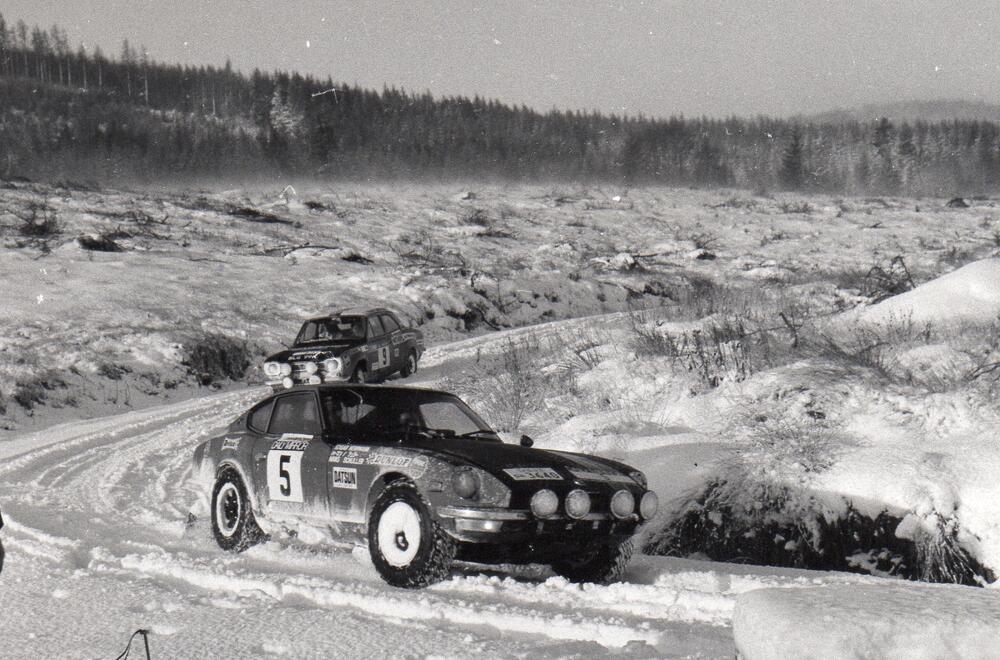

Nissan had used the little fuel/oil heat exchanger (its actually a 130-series Cedric/Gloria part) as a diff cooler on the 510-series Bluebird Works rally cars (winning the East African Safari Rally with them in 1970) and engineered a similar system for the first batch of 240Z Works rally cars (entered in the 1970 RAC Rally).

However, there was some debate over whether diff cooling would be an issue given that the RAC Rally was traditionally held in the depths of the British winter, and before the rally the team mechanics removed the heat exchangers and pumps from the cars in a quest to save weight and simplify. Cue trouble. Without the coolers the diffs got very hot indeed and that extreme heat weakened the thread locking compound on the crownwheels, causing bolts to loosen, back out and catch on the housing. Spare diffs were carried on the team service cars, but they used them all up. The replacements - of course - failed in the same way.

Aaltonen and Easter managed to nurse their car to a 7th place finish, but Fall/Phillips, Herrmann/Schuller and Bloxham/Salt all retired with differential failures. Seems the diff coolers would have been beneficial after all.