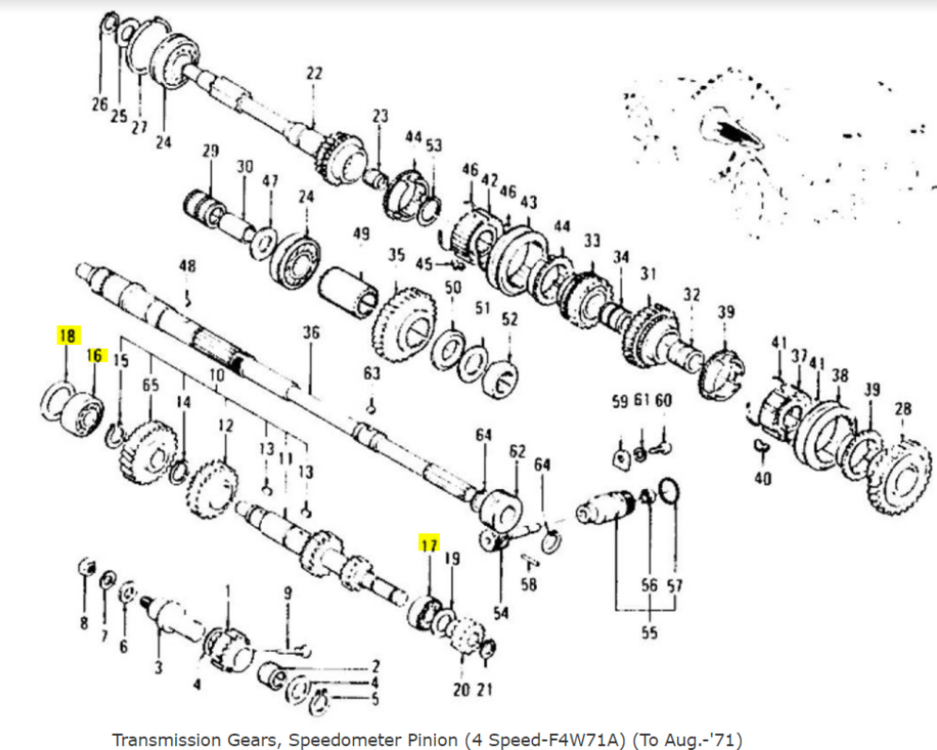

@EuroDat another question for you in the ongoing rebuild saga, item #18 below is some type of shim or spacer that goes under the counter shaft bearing in the adapter plate:

I am coming up empty on any information on the OEM thickness for this shim, it is NLA. Do you happen to have one to compare or know offhand? I am pretty sure the one in place currently is not OEM, and neither is the bearing sitting on top of it (item 16), looks like a cheap replacement. Item 17 at the other end of the counter shaft on my transmission is a Nachi bearing which is probably the OEM bearing, I am replacing both with new Nachi bearings. Just want to make sure the shim is the correct thickness, mine is a rough cut piece of aluminum with measurements O.D. - 51.5mm, I.D. 34.2mm and thickness 2.65mm.

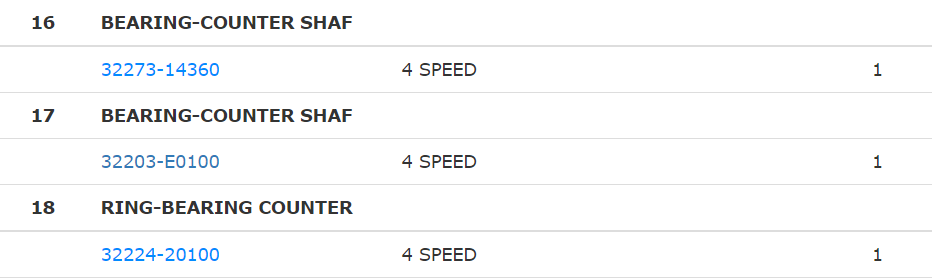

Picture of the bearing and shim:

Also, if it helps anyone in the future the countershaft bearings are listed as NLA but with a little digging I found the Nachi replacements:

Item 16: Nachi 6205 C3 Open Bearing (25mmx52mmx15mm)

Item 17: Nachi 6304 C3 Open Bearing (20mmx52mmx15mm)