(Edit: it was mark maras, madkaw, and eurodat that got me thinking it was possible and helped inspire the methods i used. I wanted to refer to their previous comments but had to go back to find their names, thanks each of ya. It's the only reason I made an account here, just to thank you.)

I just did a bit different approach to the similar problem, not with an opel but I have a Ford truck with a head gasket failure, and found it warped about .033 up in the center.

I didn't have a thick plate of steel to bolt onto, but found a girder and hoped to make it work.

The approach I took was much different, rather than air heating and cooling, I figured that oil heating would more effective to thoroughly heat everything through to temp, taking notes from the kitchen chefs, and also slowly cool it. Borrowing from old blacksmith forgings.

So far it appears that the head is not nearly as crooked, wheras before you could stand back ten feet and eyeball it and see where it warped at.

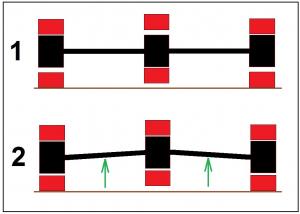

I used washers about .090 thick, heated the head, and bolted it to the cool c-beam, bastardizing a feeler gauge set to do some math and combine multiple shims to brace between the beam and head, stacked between each L-R row of head bolts:

Began with .033 warp, with .090 washers at the corners, and from what someone said here I went half the distance past center? It was a long weekend, but I basically stacked the feeler shims in a combination equal to what distance was needed, increasing in the stack sizes towards either end, with the old head bolts, nuts and lock washers on the beam side

And with an old metal oil drum cut in half, two old gasoline Coleman camp grills, a propane weedtorch, digital thermometeras well as industrial use temp needle gauge that is fitted in processing equipment, I basically deepfried the cylinder head. It had already been fried once! But this time, heated the head upside-down so the c-beam would be out of the oil, in an attempt to keep it from distorting as well, if I could manage to keep it somewhat cooler than the head and thus remain more rigid while subjecting the head to the heat, and also left the mounting bracket on the head so I could dip it in or pull it without reaching in.

I also had several fire extinguishers on hand, and a forklift to lift or lower it.

Currently, I'm looking at it, it looks like it may be straighter, but I'll admit I'm nervous to unbolt the thing. Even with the criss-cross outermost and working in, what if somehow I made it worse?