I took a break from the car to do some self care and get my mind in order by getting my tools in order. I bought myself a few packs of Toolbox Widget organizers, and so far they are doing the job. The box doesn’t hold quite as much now, but I also don’t have wrenches and sockets sliding around all over the place and piled up on top of each other.

Putting a layer of anti-slip foam on the bottom first really helps it feel slick. Not sure how I’m going to keep the dust out, though.

…

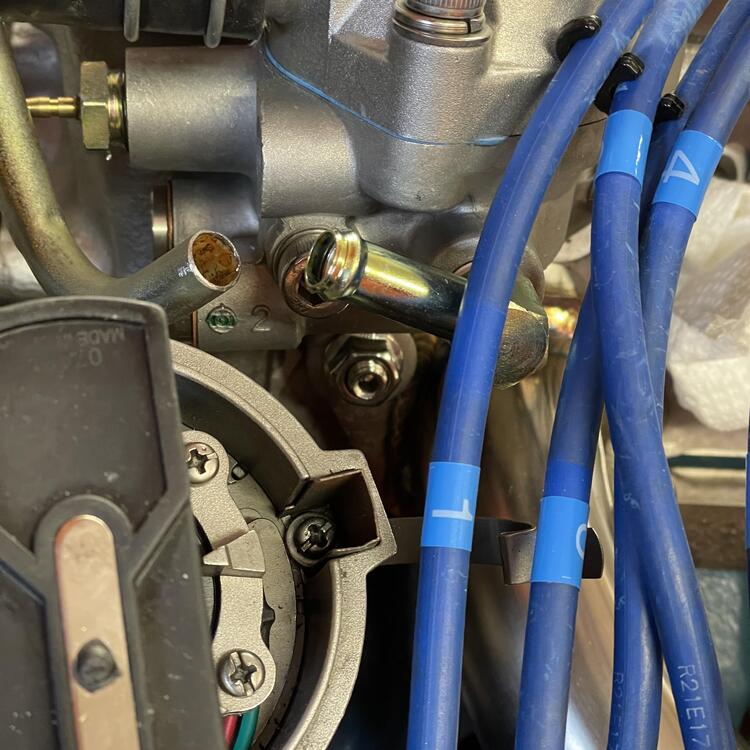

So you may remember that I was having a hard time adapting the 240z coolant routing to having Mikuni triples because that eliminates the carburetor warming channel that connects the bypass tube to the thermostat housing. I had experimented with just running a stainless steel tube in place of that system, but it fouled the manifold and front carburetor.

After much back and forth with various thermostat housings I found that the early ZX housing is the one I wanted. It has many extra ports, but these can be plugged with various fittings. The hardest one to find is the 1/4” BSPT, but McMastercarr had them.

Next I tried a few different Nissan fittings that are 1/4” BSPT male to a 3/8” hose barb. I found the 105° angled one to work best for clearing the distributor.

Then I found a 280zx bypass tube, which more or less mounts right up, but because it is meant for the fuel injection system I had to remove approx. 9” from the side that wraps around the thermostat and put a new bead at the point where I cut it. It also needed some spacers to change the geometry and allow it to clear the temperature sensor and point the tube at the 3/8” fitting mentioned above.

After that I needed a ZX water inlet with the 3/8” tube coming off the threaded adapter that connects to everything already discussed. That has a 5/8” tube pointing back to the heater hoses, so I had to replace all of my 3/4” hose. It also meant going full ZX with all of the fittings and getting rid of the 240z y-pipe. I had to find a coolant regulator/check valve, which is nearly a unicorn part. I know seller with some that are NOS in the box, and normally I wouldn’t go with used parts on a fresh engine build, but I’m not paying $175 plus shipping for something I can get for $30 in good used condition and is essentially just a 3/8” tee with a check valve.

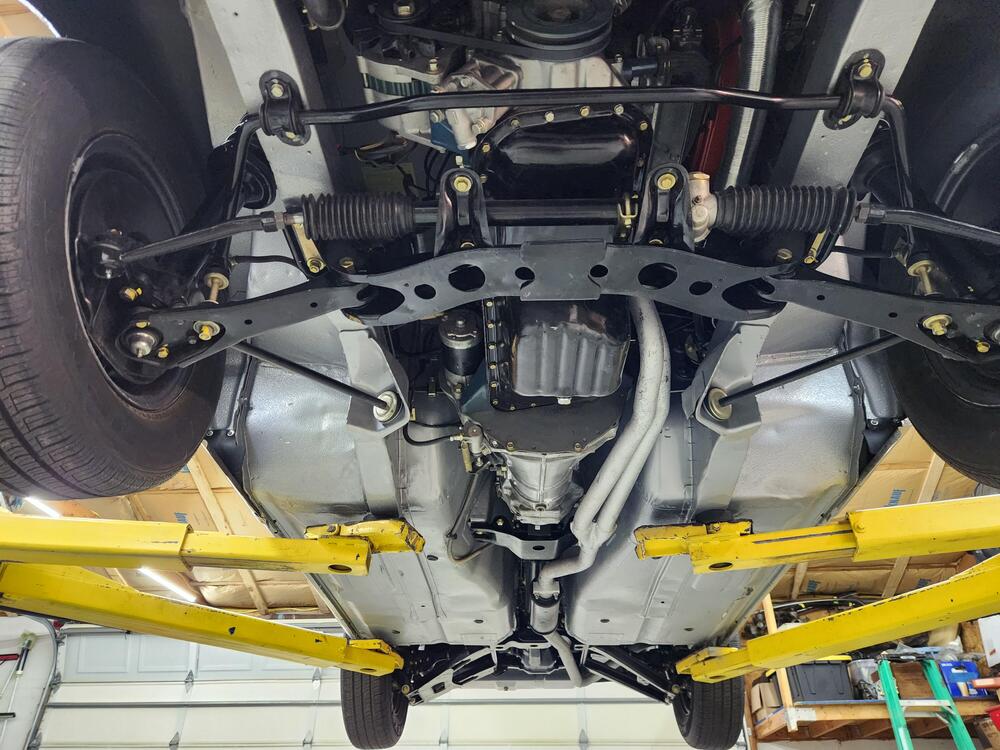

The coolant system is now closed. After much trial and error and purchasing too much hose, I have the whole system plumbed and clamped.

I only used one of the OEM 240z hoses, and I cut it down significantly. They wouldn’t have worked at all with the Vintage Air system I have, so I put a pair of their bulkhead barb to threaded fittings coupled to their 90° barb fittings. I bought a pair of Continental hoses with a bunch of turns from Summit Racing, which allowed me to keep everything under the dash pretty snug. I was worried I would need to make a bracket for the heater control valve, but it’s floating pretty far from everything so it should touch anything even with a huge amount of vibration.

So now I just need to check all my fasteners and get a radiator overflow tank. Next is decide whether to move on to the fuel system or put the AC lines in.