Today, I received some items I won from auctions in Japan. I use a third party, Jauce.com, to assist with the logistics. They handle receiving items... holding them until all are ready to export, and then packaging and sending them to me. There are many fees. There are bank fees when depositing funds. There are auction fees when you win. There are tax fees. There is shipping from the seller to the Jauce warehouse. There is the cost of shipping to the US. With all the fees and shipping, it can be difficult to determine whether what you paid was a good price. I thought it would be interesting to share a bit about my experience with purchasing and importing these items.

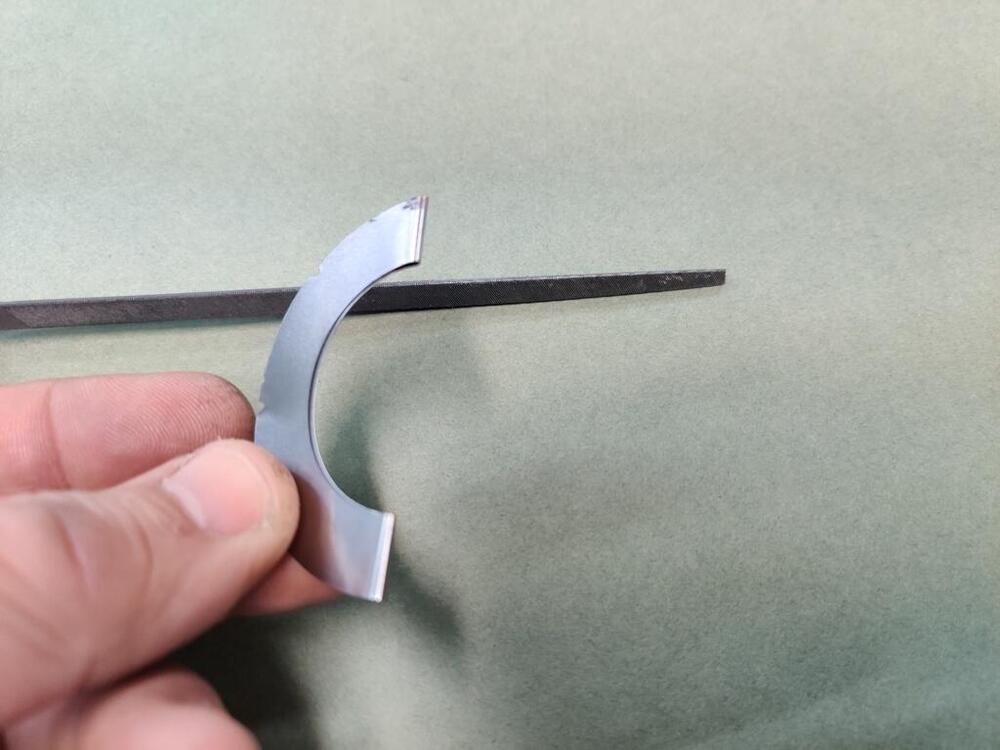

The steering wheel is a "Nissan competition replica" - this one is wood vs. others available which are vinyl. I also got several genuine Nissan parts including a front set of front bumper rubber strips (the horizontal ones), a set of matching rear bumper strips, an ignition switch, a couple of window cranks, a horn pad for the steering wheel, and a clutch slave cylinder reservoir.

Apparently someone made a batch of these replica steering wheels a while back, and you can still find them available in a few places. Generally speaking, without the horn button, you're looking at a minimum of $389 here in the US.

Pair of genuine Nissan front bumper rubber strips are discontinued and no longer available - $200.84 with free shipping from eBay

Pair of genuine Nissan rear rubber strips (the horizontal ones) $145 and $17 shipping from eBay and $66.51 plus shipping each from NissanPartsDeal.com

Original Kanto Seiki ignition switch is available on eBay for $398 plus $19 shipping

Set of two genuine Nissan window cranks $46.85 ($93.70 for two) currently, though they go on sale for about 15% off from time to time) plus shipping from NissanPartsDeal.com

A genuine Nissan horn pad for a stock steering wheel - $310 on eBay and $269 plus shipping from NissanPartsDeal.com (but not currently available)

A genuine Nissan clutch slave cylinder reservoir (old type) which is discontinued and no longer available

Adding in all the fees and allocating the final shipping to the US. proportionately per item with the final auction price with fees included, here is what I actually paid:

Replica steering wheel - $320.69

Pair of genuine Nissan front bumper rubber strips (NLA) - $96.46

Pair of genuine Nissan rear rubber strips - $109.77

Original Kanto Seiki ignition switch - $145.93

Set of two genuine Nissan window cranks - $63.16

A genuine Nissan horn pad for a stock steering wheel - $193.49

A genuine Nissan clutch slave cylinder reservoir - $21.30

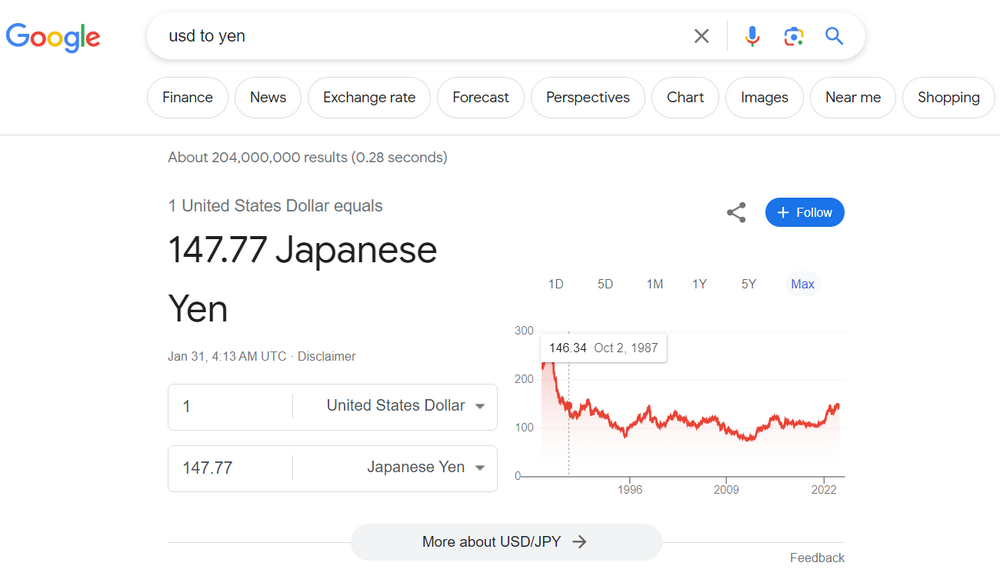

A dollar buys a lot of yen these days, historically speaking, as can be seen from the graph below. The exchange rate is pretty much what it was back in about 1987. Something to consider!

Subscriber

Subscriber 6Points1,282Posts

6Points1,282Posts Subscriber

Subscriber 3Points428Posts

3Points428Posts

.thumb.jpg.36554a7a8a1052df9098bf8213cde0cb.jpg)

.thumb.jpg.46a469740bf949f53777ae9621f7722d.jpg)