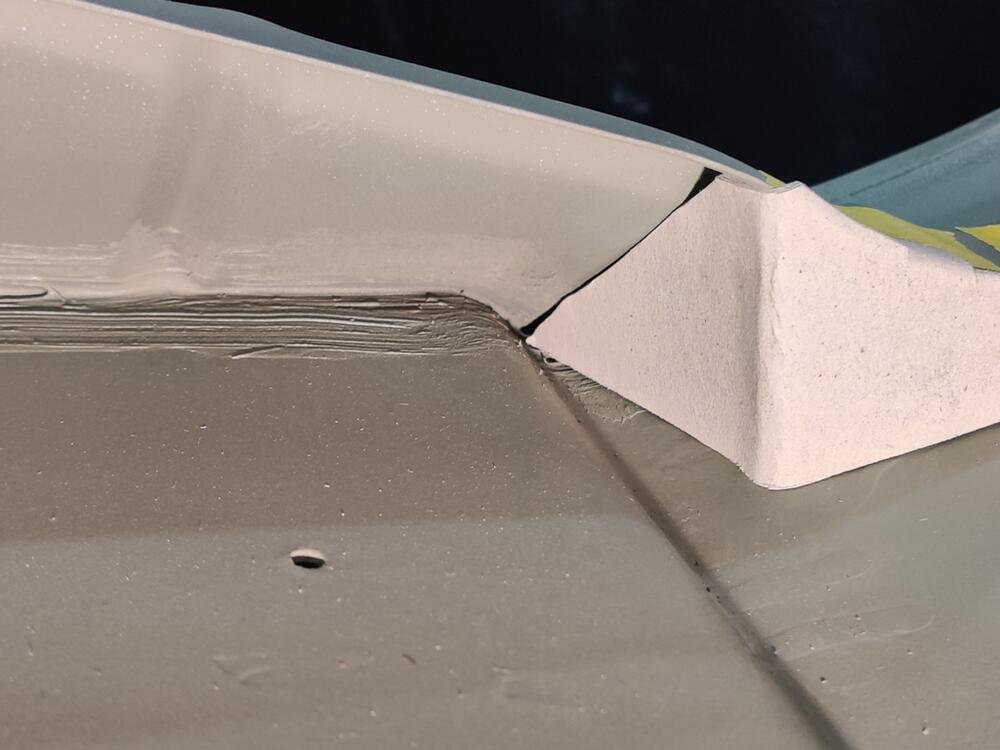

I've been thinking about how best to address one of the most common rust out areas on our cars, the bottom corner of the front fender. There is a reinforcement panel which is crimped into the back edge of the fender, and where it twists at the bottom of the fender, it creates a trap for dirt and debris, which over time, collects in the bottom rear corner. The debris which gets trapped here allows no air circulation so it holds moisture for extended periods of time, over and over again. Eventually, bare metal gets exposed and rust starts.

On my first 240Z, I bought brand new OEM fenders, and I sprayed epoxy primer inside this area along with paint. That was in 1993. Even though that car has seen relatively little weather (it has been stored in a garage for most of the years since), the lower corner of the passenger side fender started showing some raised bumps (indicating rust through from behind around 2011. I also, unbolted the bottom of that cars fenders and blew out the debris and dirt a few times over the years with compressed air. Still, these preventative efforts did not work. With the 240Z I am restoring now, I want a better solution.

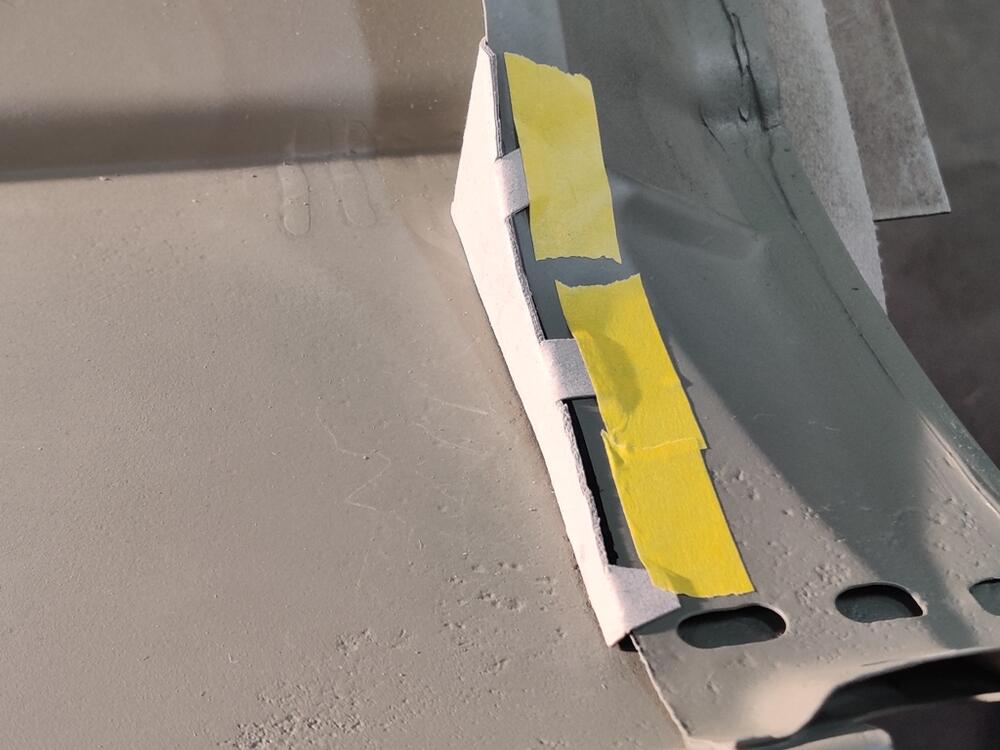

Initially, I thought I would address this problem area by cutting some oval vents to allow additional drainage from this corner, and additional air circulation for drying. However, I think that would only be a slight improvement. Instead, I now have in mind fabricating a small metal panel which will seal off this area completely, and therefore, not allowing any dirt or debris or moisture to collect in the corner at all. Here is a cardboard mock up:

I will extend the actual metal piece I fabricate a little further down than this cardboard template, so that the gap is closed. I may pop rivet this piece on using the little tabs. Once secured, I will use seam sealer to seal all the gaps. Of course, I now need to do something to seal up the oval holes that I cut into the reinforcement panel, or water and debris will enter there and I will still have the same problem for the bottom inch or so of the fender corner.

Subscriber

Subscriber 5Points3,770Posts

5Points3,770Posts Subscriber

Subscriber 4Points381Posts

4Points381Posts