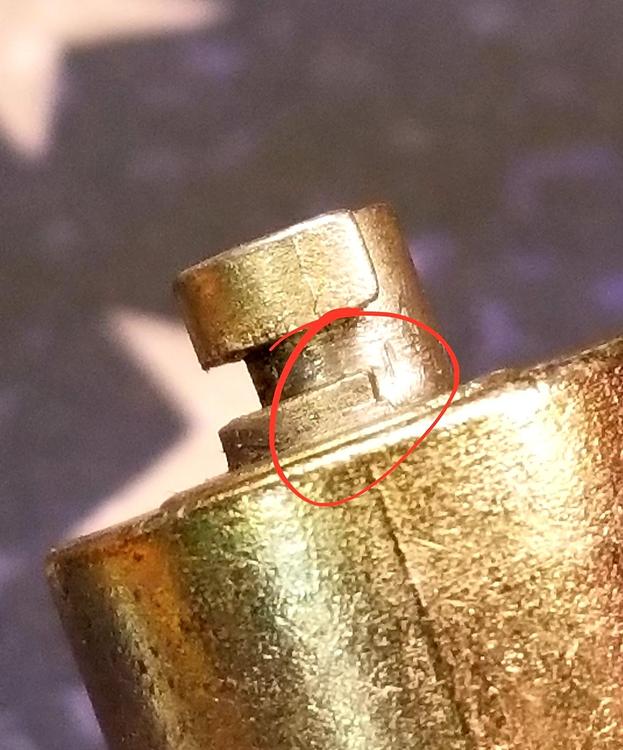

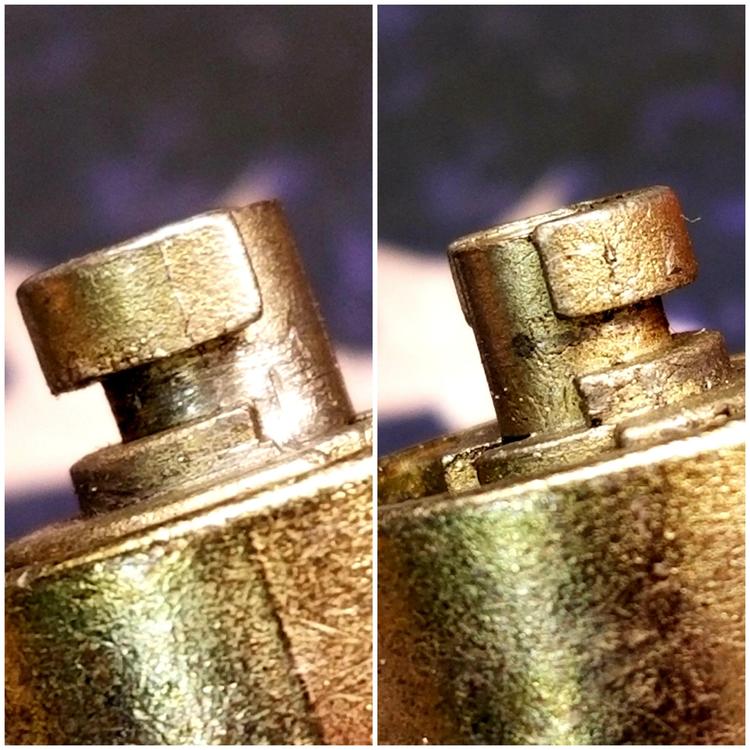

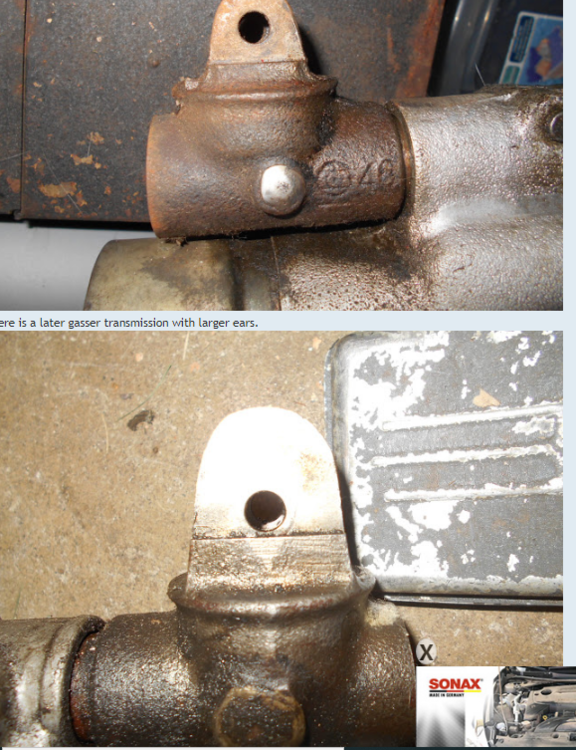

So I just bought my first Z (Yay!) and it had the same lock issue, along with a bunch of other ones. A slightly different solution worked for me, so I figured I'd share. Unfortunately, in all my excitement in getting it to work, I put everything back together before taking any pics, but will try to describe it best I can. My lock problem was as described in this and other threads. The lock cylinder looked exactly like the one pictured in this thread. I didn't have any metal wire which I would trust to retain its spring constant in the long run to make the "wire hanger" repair last. I did have some softer metal wire; one of those shiny steel types you see at hobby stores. So instead, I drilled a hole right in the location where the lock cylinder lever arm is worn down (where the metal used to be, but is now gone). Drilled straight in, perpendicular to the shaft, about 2mm deep. Then jammed a small length of wire into the whole and compressed it in there with pliers. Matched the drill bit and the wire size closely so the wire barely fit and, upon compression, the wire expanded in the hole and pretty much stayed there for good. Then file the excess wire down to resemble the original shape of the cylinder and done! If anyone wants more info, I can try to draw up some explanatory diagrams. (This probably makes a lot more sense to me than someone reading it) Hope this helps.