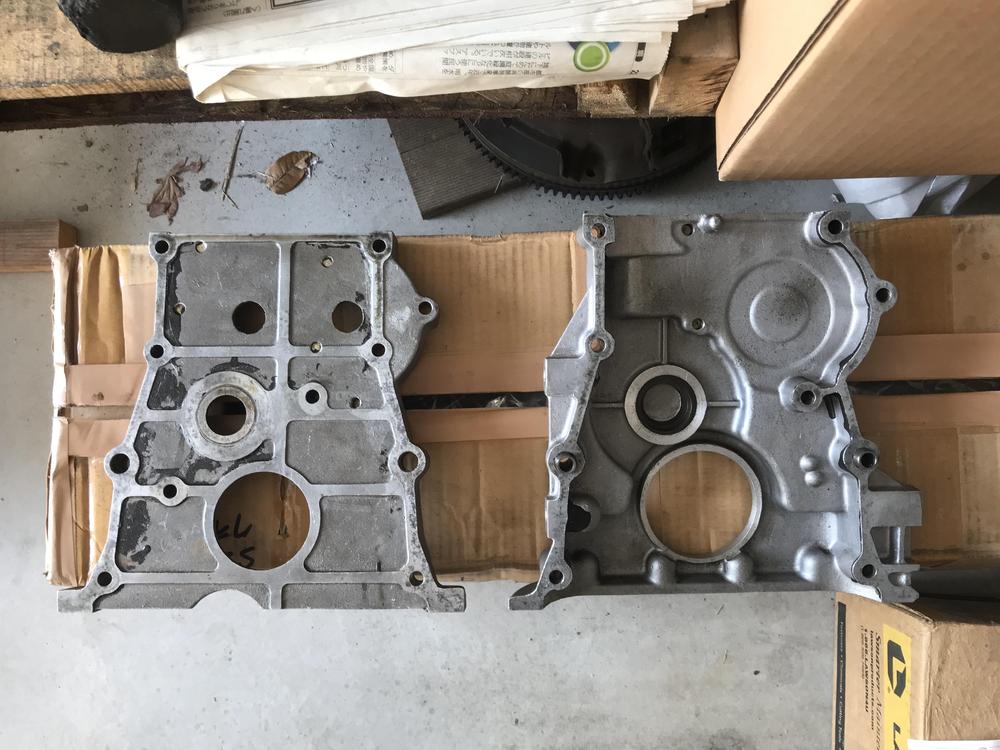

There are two techniques used for industrial plating, rack plating and barrel plating. Barrel plating is used for small parts. The parts are dumped through the hatch of a plastic barrel, the hatch is shut and the barrel is sent down the plating line. Think nuts, bolts, washers, windshield washer nozzles, hood latch parts etc. Rack plating is as the name implies, the parts are secured to a rack by fine wire or hooks. Rack plating is used for parts like the plate between the engine and transmission, long brake, clutch and fuel lines (more about these long lines later) water pump pulley, etc. Be careful, the plater may want to put some of the larger parts in the barrel so have your preferences decided ahead of time. Sometimes rack plating may leave a dark spot where the wire or hook touches the part. The more conscientious platers will work with you to minimize or eliminate the chance of the dark spot, plan ahead. Here's how I deal with the long lines. I first use Brakleen to remove any oil or grease. Then I use single O steel wool to remove any rust, paint, etc followed by the same texture steel wool to polish the lines. I have yet to find a plater with tanks large enough to plate these long lines so I carefully bend them around a 55 gallon drum making the overall length small enough for the plating tanks. Because I want to be very selective about reusing replated 50 year old lines through which flow critical fluids under pressure I always take another step. I bend and flare a complete set of new brake, clutch and fuel lines which I have plated at the same time as the original lines. I buy a length of line from my NAPA store in each of the sizes required and NAPA fittings which happen to come with the correct 10mm flats and are already plated in yellow zinc. Yes, a lot of work but when all the lines have been replated I can choose the best, and safest, of the litter. Damn, he sure goes through a lot of work but hey, I've been doing this long enough that making a new set isn't a big deal and I know I can have confidence in the finished product. Prep work for everything else - I start with brakleen - a product that doesn't leave a residue - then glass bead blasting to remove paint, rust, etc followed by many hours of tumbling in a rock tumbler filled with my small parts and crushed corn cobs. The end product will have a lightly polished finish. An excellent start to the zinc plating process. Yes, Jfa.series1, your use of wire to keep the small stuff together is an excellent idea, a must for SU carb parts. For the past 3 loads I've been using a shop just south of Philadelphia. Every time I drop off a load they ask me about the environment the parts will live in. I'm impressed by that as I had NEVER been asked that before. However, I've gotten good reports about Sav-On from more than one source. If I ever have issues with the Phila folks I'll give Sav-In a go. The Royal Pain In The arse work I've outlined is what separates a quality restoration one can be proud of from everything else. Good Hunting (plating)!