Well I wasn't there at the factory when they were swaging those bushing, but I suspect they did it in just one step. Keep in mind, however, that they have access to machines and processes that I don't. I'm also sure they heat treated their dies, and I did not. I started with a mid-hard heat treatable steel that I could heat treat to a very suitable hardness, but I figured I'm only going to be doing this a couple times, and even without the heat treat, my dies should outlast me.

So IMHO the bottom line is that I think it's possible to do it in just one operation, but I wouldn't recommend it unless you really know what you're doing (and I do not).

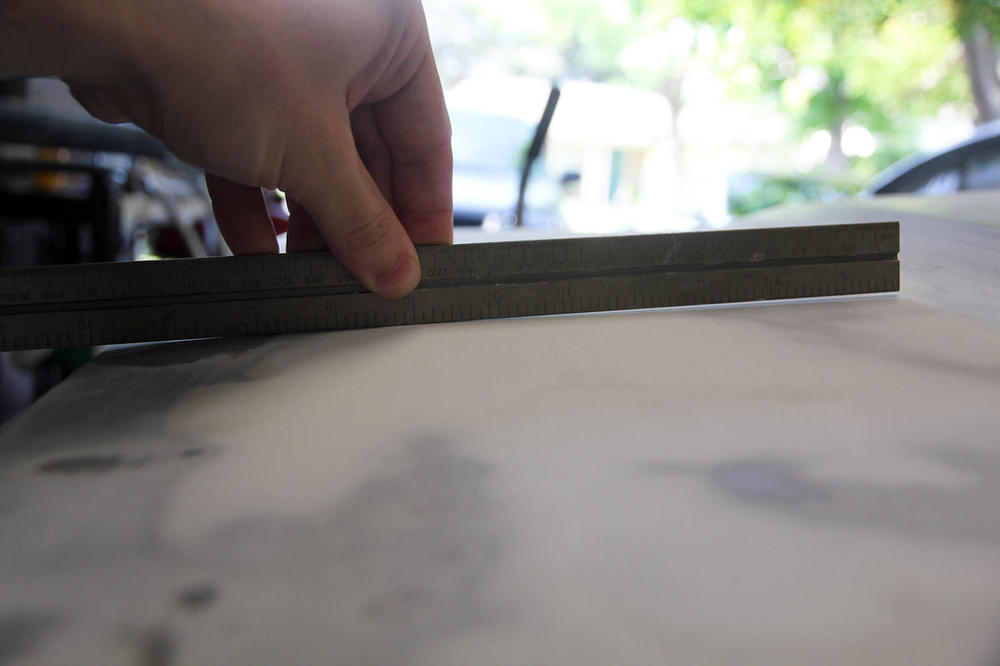

However... After going through this, I believe that I can simplify the die design. You see... The first flaring die did such a fantastic job of tapering the material outward that the curved section of the second did never even made contact with the bushing wall until the flange was pressed completely flat.

In other words... The complicated portion of the second die (the carefully radiused and polished center section) is pretty much unnecessary and that second die could look just like a donut with a hole in the middle. That raised portion isn't even necessary. In fact, I believe I could have simply flipped my tapered first die over and used the flat side to press the flange to it's final position. I think that if designed properly, you could get two forming operations from two different sides of the same die.

So, if you're looking to minimize the cost of having dies made, I would try that.

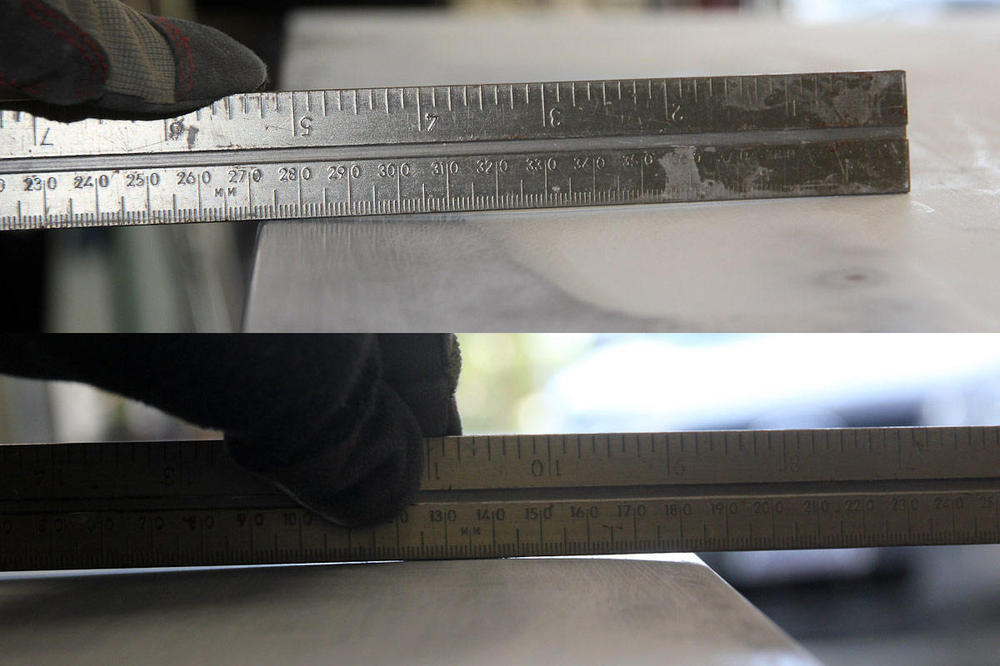

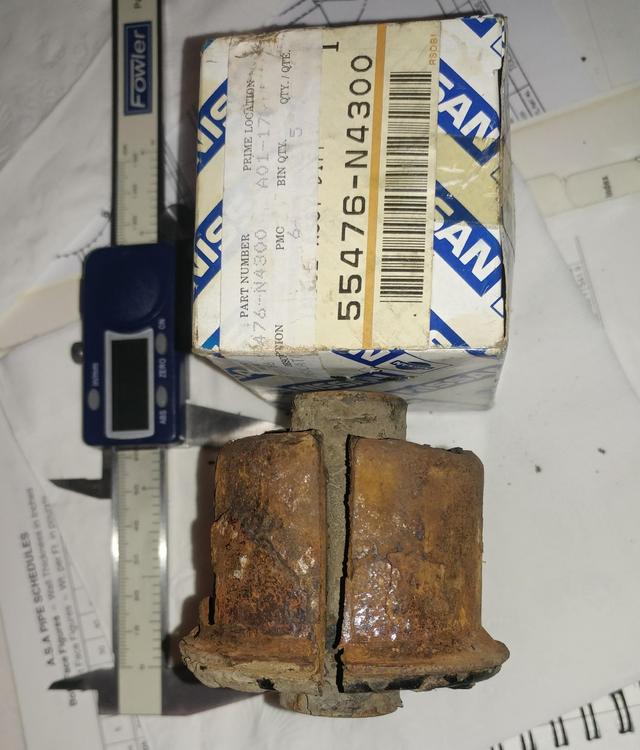

Here's a pic at the very start of the first tapering operation:

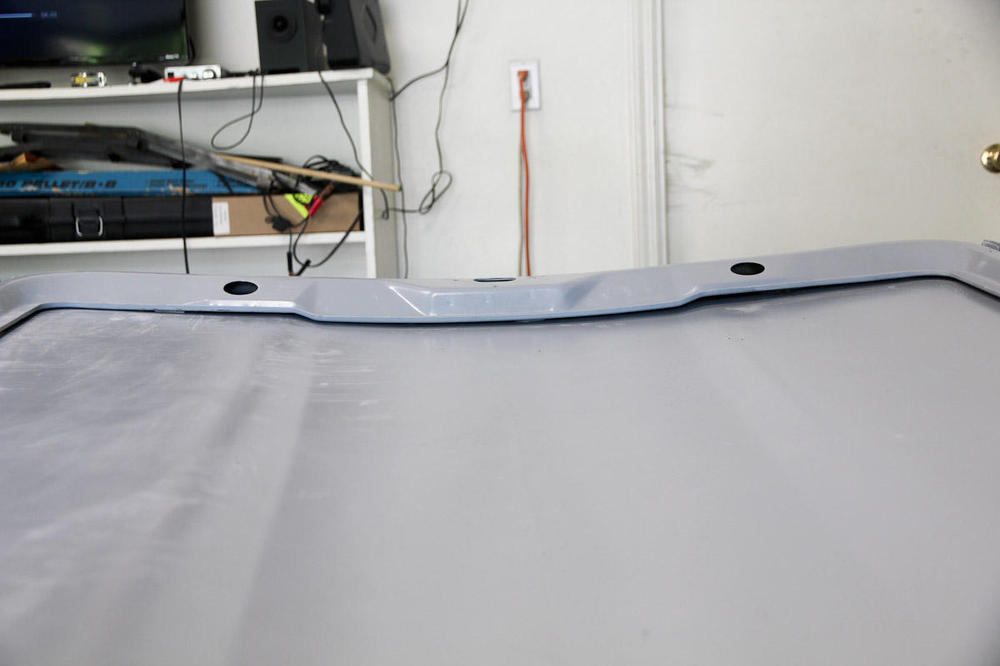

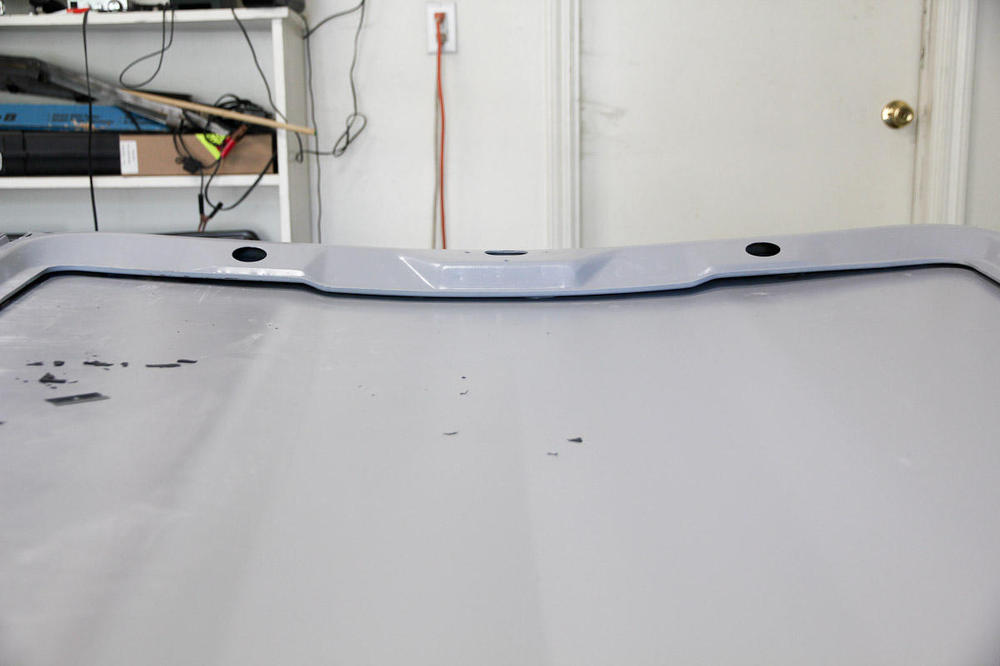

And here's how it looks fully tapered with just the first die. You can see that the material is "rolled outward" so far already that it never even contacts the curved portion of the second die:

If I had known that a the beginning, I may not have even made two dies. I may have made one "reversible" die instead and saved myself that polishing time.

Subscriber

Subscriber 3Points2,228Posts

3Points2,228Posts Subscriber

Subscriber 3Points11,142Posts

3Points11,142Posts

.thumb.jpg.16ecc7caece57094c8f0cef5c29693bf.jpg)

.thumb.jpg.2c7e175be6aa5d54fd6716965da4c230.jpg)