Leaderboard

Popular Content

Showing content with the highest reputation on 03/24/2017 in all areas

-

280z RACK RE-BUILD

2 pointsSo here's an update from my last post on the similarities / differences between the different steering racks that were used over the course of the S30 series. 1. The racks themselves are the same across both generations of steering systems. The dimensions between the two are identical (25mm rack OD) and as such the bronze sleeve bushings used on each of the rack housing are the same across all models. I can confirm that these bushings fit in either an early rack housing (manufactured up to July of 73) or a late rack housing (manufactured from August of 73 on). I have pressed bushings in both housings and they are the same. 2. There were two styles of inner tie rod ends but these do not seem to correspond to the timing of the different generation racks. I have a rack in my possession that uses the newer style inner tie rod end but was a part of the early rack generation. These later units were the ones that were welded together and not serviceable (although I do believe that Eurodat has successfully dismantled one of these and refurbished them). The earlier style inners could physically come apart although it is not clear to me what you could actually service other than cleaning it out and applying new grease. I have included a photo at the end of this post showing the 2 different generations of inner tie rod ends. 3. As I stated in my last post, the most significant difference between the two generations of racks was in the design and implementation of the pinion. The early pinion design used only a single ball bearing at the top of the pinion which was pressed onto the pinion shaft and held in place with a C clip. The bottom of the pinion rode in a bronze sleeve that is pressed into the bottom of the rack housing. As near as I can tell this sleeve bushing cannot be removed and therefore is not serviceable. This corresponds with the statement in the FSM which indicates that if there is excessive play between the bushing and the pinion, the entire housing needs to be replaced. The pinion diameter (where the ball bearing sits) is also physically bigger on the early generation (17mm versus 15mm for the later generation). The second generation pinion uses two angular contact bearings, one at the top and one at the bottom. The bottom one is actually pressed into the rack housing but can be removed with a blind bearing puller. Therefore both of these are serviceable. 4. The pinions are also secured into the rack housing differently. In the early generation, the pinion is held in the housing with a large C clip. On the newer generations the pinion is held in place with a "cover" that goes over the pinion shaft and bolts into the rack housing. 5. There are also differences in the rack adjustment system as well. The early generation uses a smaller bronze / brass "slug" (which rides on the rack) than the later generation. As a result, the adjustment screw and lock nut are smaller on the earlier racks as compared to the later ones. I have included a picture below which will highlight all of these differences. So that's it for now. If I discover anything additional, I will provide an update to this post.2 points

-

DIY Gland Nut Socket - With PICS!

1 point

-

1970 SCCA runoffs artilcle with pictures

Great read. I was THERE. I was home on mid-tour leave from Korea. Came down from Ohio with my Brother who was a D Prod TR4A racer not qualified (wrecked at MO). :-( Wife and I saw the beautiful BRE Z cars, came home in May 71, put $100 down at the Bel Air MD dealer. Top of the list in Oct..no cars...Dock strike...Dec they shipped cars from Vancouver BC. Got the pick of five Z's. Unheard of as then you got whatever came in next to the dealer. The blue and white Z has 89,000 miles and took 2nd at ZCON in Toronto last summer . Lots of Autocross trophies in Baltimore/Washington Council of Sports Car Clubs. Joe Ruffing and I did three evens in three states one Sunday. He had a 2000 that he ran the stuff out of. Fast. Miss him.1 point

-

78 280Z Electrical Fan (Not how to install)

I've seen that "cooling fan" circuit before but never seen an actual fan. There are a few things in the 280Z diagrams that don't seem to exist, but they persist in the diagrams. Have you actually found the plug at the end of the wire? I've never seen it. According to the diagram that circuit starts at the fusebox and also runs the defogger. It's a 20 amp fuse. Most of the Z car plumbing is BSPT. It's stock, to Nissan, but it's not common. The stock factory fan and fan clutch work really well. No big benefit to an E-fan.1 point

-

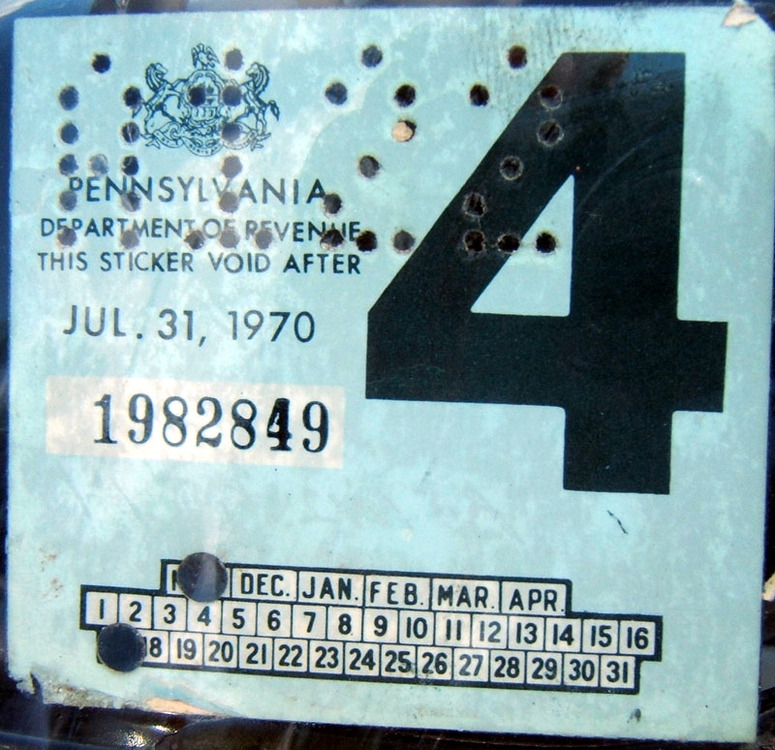

Showroom Z 1970 month???

1 point

-

1971 Series I Project for $3K in Orlando

1 point

-

1971 Series I Project for $3K in Orlando

I found its cousin in the Atlanta area: https://atlanta.craigslist.org/wat/cto/6056995502.html $1500 for a roller missing doors, glass, and most of the sheetmetal. Also what is there is somewhat rusty.1 point

-

Low miles, original paint 280z

1 point

-

This has Captain Obvious all over it

I just contacted the seller with an offer. If they bite I'll have it shipped to CO and we can divide the cost then. Anyone with a FI Z can then go to any hotel and have a tune up.1 point

-

This has Captain Obvious all over it

No, I'm a sparky. That's why I'm interested in the TIU tester.1 point

-

1971 Series I Project for $3K in Orlando

1 point

-

1971 Series I Project for $3K in Orlando

Unreal! When they sober up we'll talk. 5k!!! Insane!!1 point

-

Let's show vintage racing pictures. I'll start.

Yes, Paul says Sebring. I got lucky on today being race day though. I'm all the way across the country!1 point

-

[2017] What Did You Do To/with Your Z Today?

I was forced to drive my Z around today by this miscreant (@Captain Obvious). He demanded that I take him to the Georgia Racing Hall of Fame/Dawsonville City Hall. (Fortunately it's the same building.) We look homeless in this photo, don't we?1 point

-

[2017] What Did You Do To/with Your Z Today?

Received my Mikuni RamAir filters from the UK. With my old filters, I could not run the air horns with them.1 point

-

Amelia isl lot 244. $170k

1 point

-

L24 Battles Six S20's. Guess who wins?

Hey everyone. Thanks Alan for introducing me to this forum. What Alan said about the home prepped cars is very interesting. I was recently in a conversation with a man who's father raced a home built Z. His racing career ended like Sakurais. Interesting to think about that at the time a stock 432 demanded a much higher price than a standard L equipped Z. Now the men building these cars at home did not always have the budget to race with 432s. Some of the L series cars were built on a very low specs with low budget that barely made the cut. Where as factory cars were built with no holds barred. Even though these cars were built for the same category where they really built to the same level? Personally I think you should not base the success of a car on a single race. Nor the legacy they leave behind due to it. Racers have bad days and good days. Just like how the Ferrari had a 1st, 2nd, 3rd finish at Daytona with the P4's during a time when they were not considered a main competitor. Does this make the P4 a good car? Not really. They never achieved the same wins that they did in 67 ever again. Respect the car for what it is. Winner or looser. Unfortunately we will never know which is the "better" engine but at least it allows us to have conversations like this hah.1 point

-

Toyota 4x4 race pads

1 pointI am now sold on CarboTech pads for my 240 race car and I'm in the process of getting some truck pads made up.1 point

-

What goes on A Driving Suit?

1 pointMy wish for a better run government would be for all local, State and Federal reps and senators to wear a NASCAR style suit with all their sponsors/donors patches so everyone can see who their beholding to.... ....be nice if one of them is a SCCA patch (that they earned).1 point

-

Toyota 4x4 race pads

1 pointAll I can say is that suppliers like Carbotech http://www.ctbrakes.com/ will make up pads for you if they don't have stock. I've used their XP10 compound and found it very good if you like true race performance from your brakes.1 point

-

Early Horn Differences

1 pointHi Mike-- Your horn project looks great and your revival of an old thread is very interesting! I can't help with the date of the change to 115db, but did notice while refurbishing my 6/73 240Z original horns (both dated W7) that the color was definitely not black as was referenced in thread you provided. Comparison to many black painted objects around the house and shop helped to confirm this. The manufacturer, (Miyamotohorn) really put some quality materials into the fabrication of these horns. The paint they used was very durable---about as close to powder coated as I can imagine-- being applied 40+ years ago. I used medium grade steel wool and even a very vigorous scrubbing does not phase it. I don't know what caused the vertical barring in the paint (see left horn), but both horns exhibited this. Near as my eyes can tell the color is a very dark olive drab---and could easily be mistaken as black. In the photo, the horn on the left has only been cleaned. The one on the right has been cleaned and the painted portions re-painted to simulate the original. The closest I could come was to spray them with olive drab camouflage (too green), followed by metallic bronze (not green enough) and then a very light misting of the olive drab camouflage again to give it a slightly greenish cast. The photos do not show up these differences as well as I hoped they would, but this process satisfied my eyes and those of several neighbors I asked for opinion. The mounting ear spring assembly portion is made of high grade stainless steel and all of the mounting and assembly screws are of high grade steel that does not rust badly. The stainless mounting ears, large mounting bolts and screws were not painted nor were the backsides of the horns as your photo shows. Only the outer front ring and center portion of the horn were painted. The nut, lockwasher and screw in the center were not painted. Hopefully others will chime in with their observations and experiences regarding horn restoration and paint correctness and insight as to the date change from 110db to 115db. My theory of why the date of manufacture of the car is 6/73 while the date of the horns is 7/73 is that the car is a very late 6th month build and the fitment of the horns was in the last stages of production of the car and as a result it received horns actually made in 7/73. I should add that the car was purchased from the original owner and has full documentation of it's mileage and service records. Jim D. "Zup"1 point

-

1970 Series I 240Z Unique Parts

1 pointThe eight counterweight crankshaft described in technical bulletin TS70-28 on August 21, 1970 replaces the six counterweight crankshaft beginning with engine serial number L24-3607.1 point

-

1970 SCCA runoffs artilcle with pictures

It was something to see these two cars together again, 40 years later...1 point

.thumb.jpg.2a6b7b0f1ce874b663ec8d81bc4614ed.jpg)