Everything posted by Mike W

-

Spicer U-Joints

I have used the Spicer U-Joints on both the half shafts as well as the drive shaft and am very happy with the performance. Most recently I rebuilt a used set of half shafts using the Spicer U Joints (5-1505X) when we upgraded our diff and have had no issues with them since the initial install back in 2017. I purchased them at Autoplicity as they had the best pricing at the time. You can find them here at an even lower price that I paid almost 4 years ago. https://autoplicity.com/2016476-dana-spicer-axle-products-drivetrain-components?openOptions=True Hope that helps. Mike.

-

1973 Rebuild

The threads on the valve itself are 1/8 NPT. You would either need to get an adapter that converts that to the metric fittings on the Z lines or remake the lines with the appropriate fittings. They actually sell a version with SAE adapters included. You can find it here: https://www.speedwaymotors.com/Speedway-Motors-Brake-Proportioning-Valve-Kit-With-Fittings,387281.html As far as mounting it, I attached a 1/8 inch aluminum "plate" to the side of the valve and drilled and tapped a hole in that plate. I then used a small right angle bracket that attaches to the valve in the new tapped hole and the other side of the right angle bracket goes into the original tapped hole on the firewall that used to hold the OEM valve. You can see the "plate" that I added in the last picture that I posted above. Hope that helps. Mike.

-

1973 Rebuild

I encountered the same issue when I changed to a big brake kit from Arizona Z car including the change to discs on the rear. In my opinion the Wilwood prop valve is big and clunky and I wanted something more compact that ideally could be installed in the same position as the OEM fixed prop valve. So I ended up using this: https://www.speedwaymotors.com/Speedway-Compact-Adjustable-Brake-Proportioning-Valve,1979.html It's really small and adjustable but does require conversion fittings to adapt to metric lines. Alternatively you could change the fittings on the lines themselves to match the threads on the prop valve. I ended up having to make a new line from the splitter to the prop valve as the original one was a little short and I had to devise a way to mount it to the firewall in the same OEM location, but it all worked out. Here's a few pictures of my install. The valve works great and I have it adjusted so I get an optimal bias between the fronts and rears. Hope this helps.

-

Arghhhh Harada Intake Manifold

Well I just checked my install as I do not recall any interference problems. I ended up plugging that hole with an allen wrench style fitting and it just clears the manifold by about a millimeter or so. Here a few pictures to illustrate.

-

led bulbs

Well I located my spreadsheet for the LED bulb replacement. I have a late 260Z but pretty sure all of the bulbs for the gauges were the same. I believe that all of the bulbs I purchased came from Amazon. When I decided to do this I bought a variety of bulbs to try out and I also performed a sort of longevity test on the bulbs. I had found when I did this same thing to my F-150 a number of the LED's from Amazon burned out quickly and given the tediousness of changing them in the Z I did not want to have to deal with bad bulbs right after they got installed. So far all of mine have been perfect. Also, bear in mind that I removed my green filters so I made more room for a larger / longer bulb. If you keep your green filters in my gauge bulbs will not likely work for you. Also the only bulbs I did not convert to LED's were the blinkers as I did not feel like messing with the blinker switches / relays at the time. At some point I may go back and change them too. In any case, I've attached my spreadsheet and I hope it may help you and others out. This is definitely one of the best upgrades I've done. Mike. LED Conversion 6_10_18.xlsx

-

led bulbs

The BA9 example I used was just an example of the ones that are not sensitive to polarity so I'm not sure if these are the brightest ones you can get. When I did my interior gauges I did a lot of experimentation on bulb color, and ended up trying quite a few different options. One thing to consider is the possibility of removing the green plastic filters inside of the gauges. With the filters still installed, you will be limited to the size of the bulb you can use as the filter will restrict the bulb length. I tried both green and white bulbs with and without the filters and in the end I removed the filters and just went with white bulbs. The really light up the gauges and for the first time I can actually see how fast I am going at night! Many people like the green glow and so you can achieve that by either leaving the green filters in place or by going with a green LED bulb. I believe that I have a spread sheet of all the bulbs that I used, both inside and out, and if I can find that I will be happy to post it. Finally, the bulbs can be dimmed but you will need to change the rheostat dimmer to a PWM type dimmer in order to dim the LED bulbs. I chose to use the original dimmer and I just keep them at the highest brightness level. Hope that helps. Mike.

-

led bulbs

You can get LED's which are not sensitive to polarity and that makes this job a lot easier. Go to Super Bright LEDs dot com and they have a variety of these for our cars. Here's an example: https://www.superbrightleds.com/moreinfo/ba9s-ba7s/ba9s-led-bulb-1-led-ba9s-retrofit-car/3/ Hope that helps. Mike.

-

ZCON 2020 Hotel Impact?

ZCON is still a go as far as I know. Chris Karl posted a few times on Facebook this past weekend when he and some of his ZCON team were in Nashville locking things down. Not exactly sure how they are going to deal with the big crowds, especially at the opening and closing banquets, but I understand they have a plan. If I hear anything else I'll try and provide an update here. Mike.

-

Where to locate a fuel pump inertia kill switch

I used this exact same switch that the OP posted. I ended up mounting it on the inside of the glove box so it could not be seen and would also provide a convenient way of resetting it from inside the car in the event of it tripping. I've been running it this way for quite a number of years and have never had an issue. Hope that helps. Mike.

-

[2020] What Did You Do To/with Your Z Today?

I plan to get rid of the downdrafts and in fact already have a new stroker motor in development. Will probably be going ITB’s on this build.

-

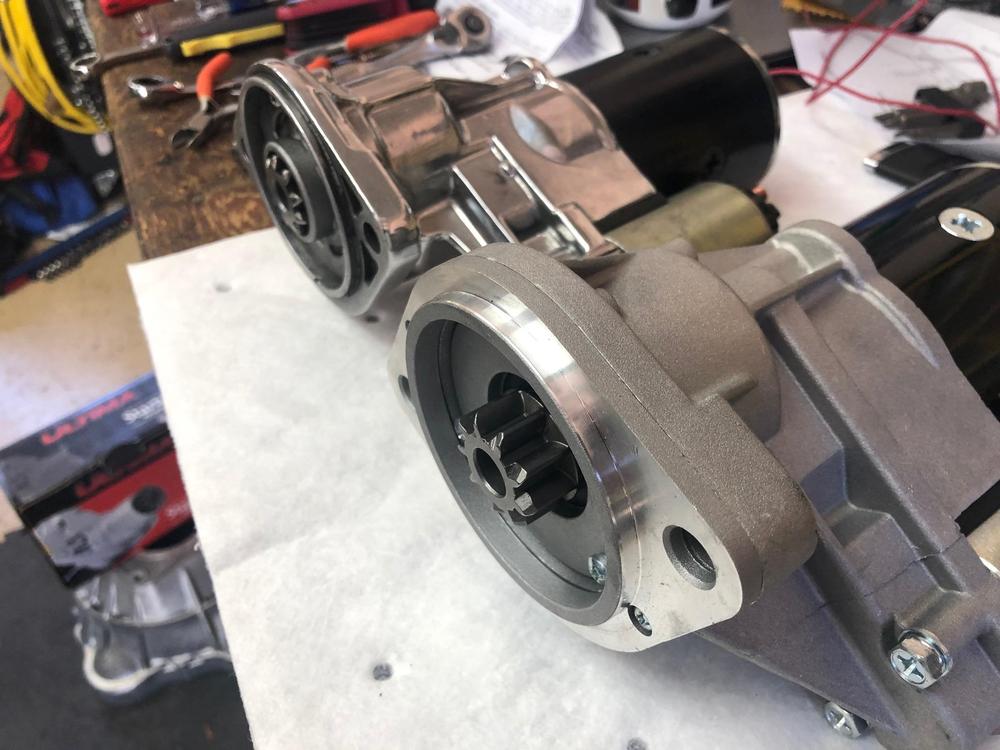

Source for BRAND NEW Gear Reduction Starters

Charles, Good to hear that someone else has used DB Electric and with positive results / reviews. They are only the distributor in this case but they appear to be a very solid company. Phil, Yes I think you can interchange a number of the individual parts. I was considering using the new motor, solenoid, gears, etc from the new one and the casing from the original Nissan one, but I haven't made that decision yet. Having said that I do think that swap would easily work. Mike.

-

Source for BRAND NEW Gear Reduction Starters

So for some reason I have not had a lot of luck with the rebuilt aftermarket starters that are available through most of the normal outlets. I have gone through numerous ones, both the original style as well as the gear reduction style, and for some reason they just don't seem to last. The most recent episode of this was while I was visiting my brothers in the Chicago area. I had hauled my Z up to my brother's home outside of Chicago and over the course of the week, we attended numerous shows and cruise ins in the area. Was a real blast until the last day, when the starter appeared to have failed. Removed it and took it to a local O'Reilly's to have it checked (my brother works there so it was an easy deal) and sure enough the starter would spin but the pinion would not extend. I ended up ordering a replacement (rebuilt) from O'Reilly's, got it installed the next day, and was back on the road again. When I returned back home to Austin, I decided that I needed to invest in a spare starter that I would keep with me when I trailered the car. From all that I had seen historically, new starters were NLA either from Nissan or aftermarket dealers, so I was resigned to the fact that I would have to go with another remanufactured version. So the search began. As I expected, all of the normal retail outlets could source a starter for me, but all were remanufactured (early as well as gear reduction style), were all in the $80-$100 range, and all required a core deposit ranging from $20-$30. So I headed over to eBay to see what I could find there. Hundreds of postings came up but on the surface, nothing new. So I hit the "new only" filter and as I expected again, the vast majority of listings were "newly remanufactured". However, as I was getting ready to leave eBay, I did notice one listing that actually said NEW, not remanufactured, so I decided to check them out. The listing was weird as the highlighted vehicles that this was meant for was a series of Massey Ferguson tractors, but further down the listing, sure enough the Nissan 280ZX was also listed. This was a gear reduction starter and so I looked at all of the pics and it almost exactly resembled the OEM one that I had on the car. After some further research I found that the supplier of this is a USA based company called DB Electrical. You can find more about them here but basically they are a distributor of auto electrical components (claim they are the biggest) and have direct relationships with the actual factories: https://www.dbelectrical.com/ After some further research I figured out that there are multiple distributors of this product and all of them list the 78 280Z as well as all years of the 280ZX. I also figured out the part number to be SHI0150. You can see details of it here: https://www.dbelectrical.com/products/starter-for-massey-ferguson-mf1010-mf1020-mf1030-mf1035-tractor.html Ironically, the part number that DB lists, item number 16584, is the exact same part number that O'Reilly's uses on the remanufactured one I purchased from them in Chicago. In any case, I decided to pull the trigger and try one out. DB had the best price $81.41, free shipping, and no core charge. Got it in a couple of days and already have it installed. The build quality is excellent, fit and finish is excellent, and most importantly it works like a champ. I have found only 2 differences from the original, but in the end they really don't matter all that much. The first is that the mounting plate of the starter is a little thicker than the original, so I had to use slightly longer bolts for the install. The only other difference is that the solenoid is clocked slightly differently than the original moving it a little closer to the fender well. No big deal and in fact made it easier to get to the top attachment bolt. All in all, very pleased so far with this upgrade. The only bad news I can give you is that it is manufactured in China and so I won't know for a while how reliable it is going to be, but from the looks of everything, I'm expecting its going to last for a while and can't be any worse than all of the remanufactured ones, which are probably also done in China. Here's some pics for your enjoyment. Hope this helps some others. Mike.

-

Switch from Cannon to Harada Triple Manifold

Here's a link to the same person in Japan that I bought mine from 4-5 years ago: https://www.ebay.com/itm/Datsun-240Z-260z-280z-Harada-Intake-manifold-for-triple-Mikuni-Webers/283568679779?hash=item420602ab63:g:upIAAOSwVvBdRLCj @Rio24 I do not recall that my issue was worse with heat soak. It seemed to happen all of the time so perhaps you are dealing with something a little different. Mike.

-

Switch from Cannon to Harada Triple Manifold

@Rio24 Yes I had a rather severe return to idle issue with my old Cannon manifold and it certainly contributed to the problem, but the manifold itself was not the only issue. The main issue with the Cannon wrt this problem is that the 3 heim joints do not line up and I found on my setup that this misalignment caused excessive friction and a very slow return to idle. I had to use rather heave return springs which really impacted the drivability of the car and so I needed to find a better solution. I ended up eliminating the center joint but doing this made the main throttle rod less stable and so I ended up going with larger heim joints and a heftier throttle rod. This change definitely helped the return to idle but did not eliminate it completely. The final solution to this, at least in my situation, was to replace the old worn OEM throttle linkage with a throttle cable. I used a universal throttle cable from Lokar and in the end this solved the return to idle problem. I was also able to change the return springs to something lighter and this really helped with the drivability. When I went to the Harada, I was able to eliminate all of the return springs except for the one that was integrated into the Harada. It really cleaned up the engine bay and also helped with drivability. You can also adjust the spring rate on the Harada and dial it in so it works in your setup. I would say that the biggest change to this problem was going away from the OEM stock linkage and replacing it with the throttle cable. I fought the OEM linkage for years and wish I had made the change to the cable long before I did. In any case, I hope that helps. If you have any other questions just let me know. Mike.

-

Firepower

I can probably help you with the 123 ignition. I believe that I was one of the first to actually install and use this in a Z and did a pretty extensive write up after I completed the install. You can find my thread here: All in all I am very happy with the system although there are a few quirks you should know about before you start. A quick summary for you: 1. On install the instructions will tell you to get the engine to TDC, install the 123 and apply power, and then turn it in the direction of rotation until a little green LED lights up. In theory that should put the 123 also at TDC with 0 degrees advance. Well that was not the case with mine. After I completed the install I programmed the 123 with a 0 degree advance curve and checked my timing at idle. It should have been at TDC but in fact I was about 12 degrees advanced. So I ended up loosening the dizzy like you would the oem one, and just turned it until I was at TDC at idle. 2. If you are running an MSD with the 123, you will likely experience random rotor failure over time. It turns out that the 123 rotor has an internal resistor embedded between the top contact and the end contact and it was not designed for use with an MSD type of ignition and will eventually burn out the resistor making the rotor useless. You can either carry spares (which is what I did until recently when I discovered the root cause of this issue)or you can Dremel out an old rotor and replace the resistor with a 12 GA wire. Interesting that 123 actually sells these modified rotors on their website so clearly then know about this weakness. Those are the 2 main issues that I recall. Other than that it is a breeze to program (I have the USB version) and performs well. Feel free to PM me if you have other questions or just respond to this thread. Hope that helps. Mike.

-

Do NOT buy a 123ignition distributor.

Thanks Blue for the compliments!! My engine bay is actually toned down a little now from the way it was in Memphis. I've replaced my valve cover with one that is powder coated black, moved the breather to the back of the cover, and routed my wires around the front of the cover rather than over it. You see more of the engine that way and given that its black its easier on the eyes!! Haha! Here's an update picture.

-

Do NOT buy a 123ignition distributor.

I was one of the first people to use the 123 ignition on a Z and I have been running this setup since 2015. I concur that the setup and install instructions are lacking and I too experienced an advanced timing situation after the initial "LED Install" procedure but unfortunately did not realize this for quite some time so I was running more advanced that I originally thought. Fortunately nothing catastrophic happened to my engine and I was able to correct this by checking the initial settings with a timing light. Although the 123 people indicated in their emails to the OP that timing should always be checked with a light, I have not seen that written in any of their instructions although it is possible that I might have missed it. One other issue that I have had with the 123 ignition is that periodically my car will refuse to start or it does start but does not run correctly (misfires) and the only thing that solves the issue is to replace the rotor. I was never able to completely figure out the cause of this or why the rotor just seemed to randomly "go bad" until I read through this thread and subsequently did some additional research. As it turns out, I also run an MSD with my ignition and when I was first considering the 123 distributor, I found a warning on their website that said not to use the 123 system with an MSD ignition. I did not understand the engineering reasoning behind this so I contacted the company directly to find out a little more. Their engineers told me that they already had customers using their product with an MSD with no issues being reported and so they really didn't seem to know why that warning was there. They basically told me that it should work without issues. Well fast forward to today and after a little more research I found the root cause of the problem. I happened to stumble on a Triumph TR site where the OP had a similar problem on a 123 ignition although in this case the rotor was actually burned. This led me to another thread on a forum called Pelican Parts and they apparently specialize in parts for older European cars. Well as it turns out, the engineers at 123 chose a readily available, off the shelf distributor where they could house their electronics and just change the drive mechanism to work with numerous different cars. So the cap and rotor, and I suspect even the dizzy body itself was very widely used in VW's, BMW's, Volvo's, etc of the late 60's going through the early 80's. Well during this time, the EU apparently was focused on RFI suppression in newer cars and mandated that auto electronics include RFI suppression hardware. I do not know exactly when this was mandated but I believe it was sometime in the 70's. Well believe it or not this mandate resulted in the inclusion of a resistor in the distributor rotor that sits between the center contact and the end contact. What I learned from the Pelican Parts forum (where a lot of these guys use this same cap and rotor setup as the 123 ignition as that's what the car originally came with) but they have also upgraded to MSD. Unfortunately these rotors with the internal resistors were designed and used at a time when ignition systems were not as powerful as today's systems, including MSD, and so the higher output power of the MSD essentially burns out the resistors over time. I must admit that I thought this seemed rather absurd as I had never heard of such a thing, but I happened to have a number of rotors that had "gone bad" so I decided to do my own checking. Well sure enough when I checked continuity between the center and end conductors, it was a total open! I really couldn't believe what I was seeing so I used a Dremel to cut away at the epoxy and sure enough buried under the epoxy and between the 2 conductors was a burned out resistor. The solution that I also found on the Pelican Parts forum was the Dremel out the epoxy and resistor and simply solder in a 12 gauge piece of wire to replace the resistor, and then simply use JB weld or some other suitable epoxy to seal it back up. You can find more info about this here: http://forums.pelicanparts.com/porsche-911-technical-forum/596559-msd-rotor-modification-detail.html Ironically, 123 Ignition now also sells a modified rotor that replaces the resistor with a wire: https://123ignitionusa.com/oem-rotor-modified-no-resistor-for-all-4-and-6-cyl-123-applications/ $45 for a rotor seemed a little excessive to me so I purchased a couple of Bosch rotors (p/n 04008) and did the mod myself. A little tedious but definitely better than paying $45. So after 4+ years of dealing with this random problem I believe it is finally solved. I will also say that despite some of the startup issues that I and others have had with the 123 system, I am very satisfied with the end result and would not hesitate to use this again. Fortunately my experience with the company and the product was a little more positive than the OP. I hope this helps others that may have experienced the same issue and that I've saved you from pulling your hair out as well. Mike.

-

Home Built Z 'Full video build'

I was one of the earliest users of the 123 ignition in a Z car and so have quite a bit of experience with it over the years that I have used it. I can also tell you that I had a similar advance problem at idle with my initial install. If I remember correctly, and according to the install instructions, everything needs to be at TDC on the engine. You install the 123 distributor, apply power, and turn it until an LED turns on and that's where you are supposed to lock the distributor in place. However, after some trial and error, I figured out that at idle I was at about 30 degrees advanced, and this was with a flat 0 degree advance programmed into the 123 distributor. I ultimately concluded that the distributor was not rotated to the proper point for a 0 degree advance, despite the fact that it had been installed properly (with the LED) as per the instructions. So what I ended up doing was unlocking the distributor, ensuring it was programmed for a 0 degree advance (up to about 1500 RPM's), and rotated the distributor until I was at 0 degrees as measured with a timing light. I then programmed in some additional advance at idle (I believe about 12 degrees) and double checked it with a timing light to ensure it agreed with the programmed values. So for some reason the LED install instructions did not work in my application, but by setting the initial timing of the 123 like you would a normal distributor, I was able to get it to work as expected. And the ease of changing timing curves is awesome. In any case, hope that helps. If you have any other questions on this just let me know. Mike.

-

Issues with mobile app

For the last few weeks every time I try to open the mobile app I get an "Invalid License" error message. It continues to say "This forum is currently not available on this app. Please contact the forum administrator." Is anyone else having this problem? Mike.

-

Very Cool Ignition Upgrade

Really glad this helped out!! Before I used the 123 system I ran a Mallory Unilite with the MSD box but found that the tach would not operate properly with the tach signal from the MSD. I tried a couple of different adapters, both passive and active, and the active one worked best, so that's whats in my car. However, it should not be required just to get the car to run. It is only used to provide a proper signal to the tach so it works correctly. Mike.

-

Very Cool Ignition Upgrade

OK. I'm the original poster on this thread and may have been the first, or one of the firsts, to use the 123 ignition on an L6 Z engine. I also use an MSD 6AL on mine and have had no issues with it since it was originally installed. I will say that when I was first contemplating using the 123 system, there was a note I believe on the 123 Ignition site in Europe, that indicated using a multi spark ignition system with the 123 was not recommended. I ended up contacting their US rep who put me in touch with their chief engineer in Europe so I could understand more about the MSD issue. Turns out that no one had ever really done this before with the 123 system and the engineer really didn't see any reason why it wouldn't work. So I went ahead and completed the install with the 123 dizzy and the MSD 6AL. So far I have not had any real issues with this system and I would characterize this as one of the best upgrades that I have done. Makes changing the timing curves a snap. I've attached the wiring diagram I drew up when I first did the install (including wire colors). I will provide one word of caution / advice on the original install. According to the 123 install directions, once you get the dizzy physically installed, you need to turn the unit until the green light just comes on. This assumes that your engine is at TDC and this "green light calibration" is intended to get the dizzy in timing sync with the engine. In other words this calibration should result in the dizzy being at TDC with 0 degrees of advance. However, after some trial and error, I found that this initial position actually introduced an advance of about 10 degrees so when I thought I was at 0 degrees, I was really at 10 degrees BTDC. So my advice is that once you have the dizzy initially installed and "calibrated" using the green light method, load a 0 degree advance program into the 123 unit and check your timing at idle with a timing light. Ideally, it should show that you are at 0 degrees advance, but if in fact it is off (like mine was) you will need to loosen the dizzy mounting clamp and turn the dizzy until you read TDC. Once you have this set as a 0 degree baseline, you can then load in programs with the desired advance curve. Hope that helps. Let me know if you have any other questions. Mike. 123 Wiring 2_19_14.pptx

-

1973 Rebuild

Thanks for the nice words!! All four corners are the same wheels. 16 x 8.25. Weird size but that's what they are. Rubbing in the rear occurred on the outer lip. At 0 offset there are no issues on the inside at all. Plenty of clearance with the strut and spring. Mike.

-

Shop says they can't perform an alignment

I would have to check my CD microfiche to see exactly when they changed the design of the rack, but I do believe that the Captain is correct that it was around the time of the 260 transition. As far as 260 manufacture dates, I'm pretty sure that the "small bumper" 260 ended production in 8/74 and the "large bumper" 260 went from 9/74 to 11/74. My car is a large bumper 260Z and has an 11/74 manufacture date. I believe that it was one of the last 260's to be built (for the US market). I agree with the other comments about the rack bushings. Those definitely need to be changed. If that does not completely cure the problem, you may consider changing out the inner / outer tie rod ends or perhaps source one of the new racks that have become available recently. Mike.

-

1973 Rebuild

I'm going to chime in on this as I just went through a very lengthy exercise to source a new set of tires and wheels for my car. So for reference, mine is a late manufacture 260Z (read that as 280Z). I run Eibach lowering springs and Tokiko illuminas. My present setup uses 16 x 7" Konig Rewinds (0 offset) on Michelin Pilot Sport 225-50X16. I have zero clearance problems on the front and some very minor rubbing on the rear when I go over hard bumps at speed. Rolling the rear fenders solved 90% of that problem. My only regret is that I did not do the rolling before the car was painted which made the task a lot more challenging. I would suggest that if you are going to go with a more aggressive setup that you have your fenders rolled prior to paint. My initial motivation was to get a set of real summer tires that would provide a stickier grip for summer driving. I really liked the Michelins I have on the car now, but they are more of an all season tire and I really wanted to switch to a summer tire. In discussing this with my son Alex (and for those of you who know him, his feedback will not be surprising), his input was "Hey dad, if you are going to get new tires, you may as well get a new set of wheels as well so you have the option of switching tires and wheels and achieving a different look". Extra expense aside, his feedback made sense to me so I was off to the races seeking a new set of wheels and tires for my car. On the wheels, I really wanted something that was different from the most common wheels used on the S30's (ie Watanabe's, Konig's, Enkei's, etc) but I had no idea that finding something a little out of the ordinary was going to be so difficult. The big issue here is finding a wheels with the right bolt pattern and the right offset with a width that will not interfere. For the front, I found that a 0 offset was ideal but try finding a modern, non-standard Z wheel that is visually appealing and meets all of the specs. I spent weeks looking for something suitable and frankly only came up with a couple of options and almost all of them were wider than what I was already running (either 8 or 8.25" wide) and this raised concern about clearance in the front. As it turns out, a 0 offset will clear the strut and spring and will also clear the fenders. The strut clearance is acceptable but it does not provide a lot of room for error, so in my opinion any wheels with a positive offset would potentially interfere with the strut / spring and a negative offset would likely result in fender clearance problems. The rears are a lot more forgiving on the strut side but I wanted wheels to match the front so I also decided to go with 0 offset for the rears as well. So in the end I decided on a set of XXR's in Chromium Black, 16 x 8.25, 0 offset. Unfortunately I did not find a lot of summer tires that would fit this wheel, but ended up with Pirelli Trofeo R's. They are basically track tires meant to be used on the street, and are pretty aggressive, very soft compound, and sticky as hell. I also decided that I wanted to try a staggered tire setup as I do like the visual look of slightly larger tires on the rear than on the front. Totally understand the downside of doing this (ie can't rotate, etc) but my main motivation was visual appearance along with acceptable performance. So in the end, I went with 225-50x16 up front and 245-45x16 in the rear. Finally, I am not a huge fan of black wheels and had a high level of concern about how these were going to look, but my son convinced me to go for it, which I did. Fortunately, these are powercoated in chromium black and so look more chrome than black depending on the lighting, so I am quite happy with the end result. In any case a long winded story to a simple question, but I do hope it helps those trying to find something that's a little different than the ordinary. I will say that the easiest way to solve this problem would have been to go for a set of complete custom wheels made to my exact specs, but in checking into this as an option the cost was through the roof. For what it would have cost for one custom wheel, I got a complete set of 4 with money left over to put towards my tires. So that is definitely an option, but you better have deep pockets if you plan to go that route. Here's a few pictures with the final result.

-

Brake Fluid

So to add a little controversy to this discussion, I have had raging debates with a number of my Z club members about the wisdom of using Dot 5 silicon fluid versus the more conventional Dot 3/4 fluid. To me the benefits of using a non corrosive fluid (to paint) out weighed the negatives that I had read about Dot 5, so I gave it a try about 2 years ago when I installed a big brake kit on my car. I can say for certain that I do not have poor pedal feel and in fact my pedal feels a little better than with Dot 3/4. I have not noticed any differences in stopping power, although with the big brake kit installed, my car stopped significantly better than with the stock setup. Based on my experience, I have been very happy with the Dot 5 and it also gives me some peace of mind wrt paint corrosion. Having said that, if I were tracking my car or using it in other really high performance situations, I would probably stick with Dot 3/4 as it does have better characteristics under those conditions. Having said that, switching over to Dot 5 and actually using it is a little trickier than Dot 3/4. First if you have been using Dot 3/4, you will need to completely flush your brake system as the 2 fluids are not compatible. Second, for some reason the Dot 5 fluid tends to hold onto air bubbles and so you need to be really careful when you pour it into your reservoirs or into a pressure bleeding system. I use a pressure bleeding system and will let the fluid sit in the container for a few hours to let the air bubbles escape. I will also usually bleed the brakes completely, let the car sit for 12-24 hours and then bleed again. I have found that doing it this way lets me get all of the air out of the system and results in a very good pedal feel. Hope that helps. Let the controversy begin!! Mike.